July 2022

Dehydrating for Cruising Cuisine

Home-prepared foods that travel well and taste great

Sponsored By WoodenBoat School

July 2022

Home-prepared foods that travel well and taste great

June 2022

Running without rowing

May 2022

An interlocking plywood frame for hand-truck wheels

April 2022

Taming Paper in an Open Boat

March 2022

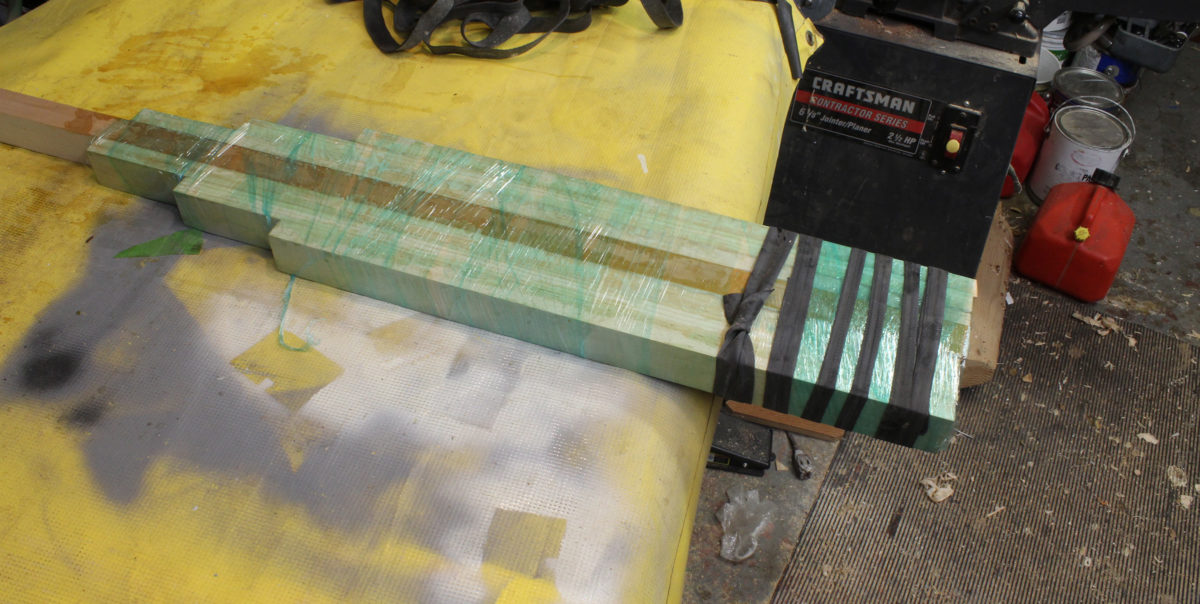

Clamping with stretch wrap and inner tubes

February 2022

Removable panels to protect and preserve

January 2022

DIY devices for forward-facing stand-up rowing

December 2021

Maintenance for long-term storage

November 2021

A table-saw accessory for ripping and crosscutting

November 2021

Better support for boats

October 2021

Replacing fabric with plywood

September 2021

Snap-on oar sleeves for rowing into a headwind

August 2021

Quick and simple protection for oars

July 2021

Comfort in close quarters

June 2021

An epoxy cure for weathered plywood

Small Boats Annual 2022May 2021

Safe towing to the ramp and back

April 2021

Leather and compound for sharper tools

March 2021

Trying a boat on for size

February 2021

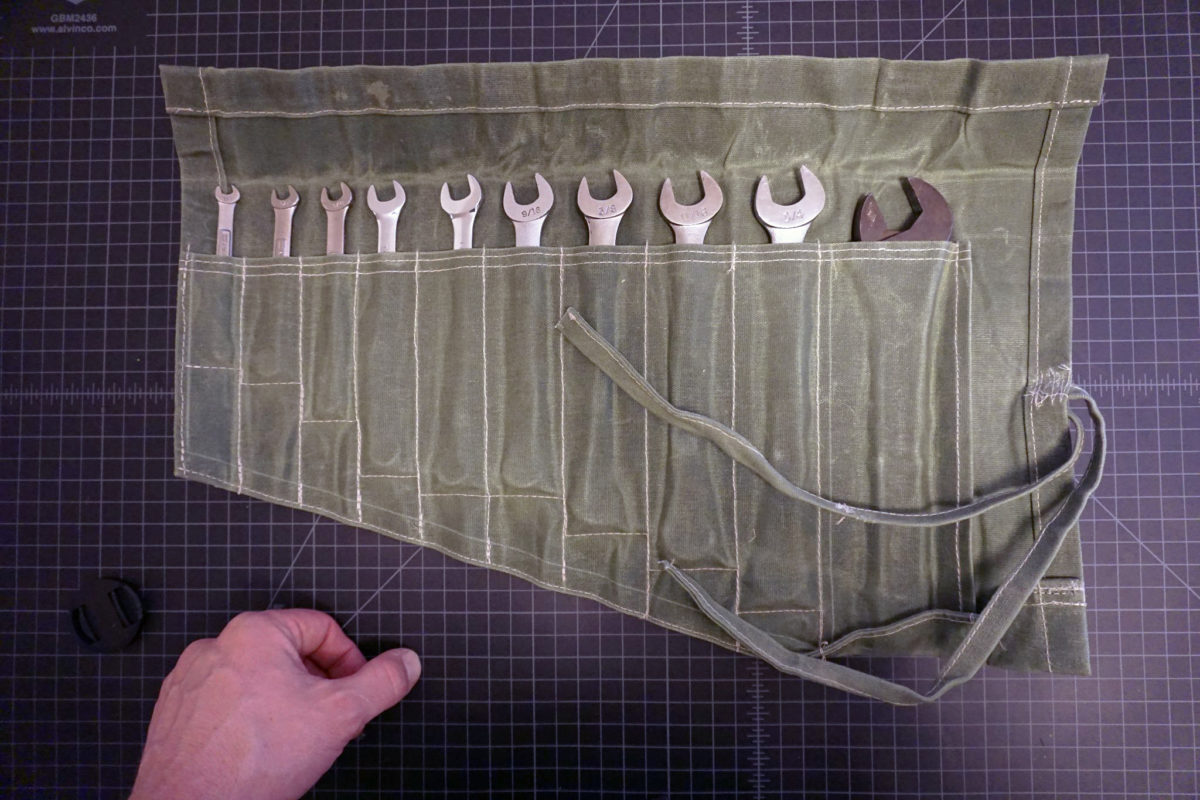

Classic fabric for home-sewn projects

9

Small Boats Annual 2008

A guide to orderly storage and transport

January 2021

DIY projects to make yourself heard

December 2020

A handful of useful projects

November 2020

An Evolution from the Joggle Stick

October 2020

Quick and hole-free strips

September 2020

An important element of boat trim