I had never thought that stropping a newly sharpened edge on a cutting tool did much. A few swipes back and forth on a piece of leather would break off the tiny burr left by the stone and that was about it. I knew that when barbers used straight razors they stropped the blade before giving a customer a shave, but didn’t take the hint that stropping is the key to a truly sharp edge.

Leather, I’ve learned, contains silicates—mineral cousins to the silicates in garnet sandpaper—which serve as an abrasive for honing metal. Horsehide has a higher concentration of silicates than cowhide and was the material favored for straight-razor strops. The steel edge of a straight razor is so fine that shaving can distort it and a strop works not only by wearing away a bit of metal, but also by pressing wobbles straight and burnishing thick and thin areas to make the edge uniform again.

The blades of woodworking tools are sturdier and need the help of stropping compounds added to the leather to speed sharpening. Some of these abrasives come in wax bars with different grits, each with a different color. Two of the most common compounds are white—aluminum oxide, comparable to a 2,000-grit stone—and green—chromium oxide, comparable to 6,000 grit.

Photographs by the author

Photographs by the authorEach strop gets two pieces of leather with one side flesh side out and the other grain side out.

The strops used for woodworking tools are not loose straps like the barbers use, but stiff leather mounted on wood blocks, usually with one side having the finished surface (grain side) out, the other side with the rough surface (flesh side) out. Vegetable-tanned leather is often favored for strops because it has a high concentration of silicates, but any stiff leather will work when stropping compounds are used. If you have any latigo left over from putting leathers on your oars, it will work well as a strop. I had a roll of stiff 1/8″-thick vegetable-tanned leather—bought at a thrift store—and used it to make a few strops. For the blocks to support the leather I used scraps of 3/4″ vertical-grain Douglas-fir, then glued slightly oversized pieces of leather to them with contact cement and trimmed the leather with a sharp knife.

I glued the leather to the wooden bases with contact cement and used a heavy steel roller to assure good, uniform bonds.

For most of my strops, the rough flesh-side gets an application of white compound and the grain side gets green. It doesn’t take much compound to charge the leather. Just rub the stick over the leather until the compound gives its color to the strop. If the compound begins to gather in lumps, warming it up (I used a heat gun) softens it and you can rub it smooth with your fingers.

My finished strops have been trimmed and are ready for use with or without compound.

Stropping is for honing an edge that has already been properly shaped with a sharpening stone. The strop will smooth the scoring left by the stone and make the edge noticeably sharper, and the edge can be maintained with the strop many times before it’s time to return to the sharpening stone. Since stropping removes very little steel, your blades will not age as quickly as they would if only sharpened by a stone.

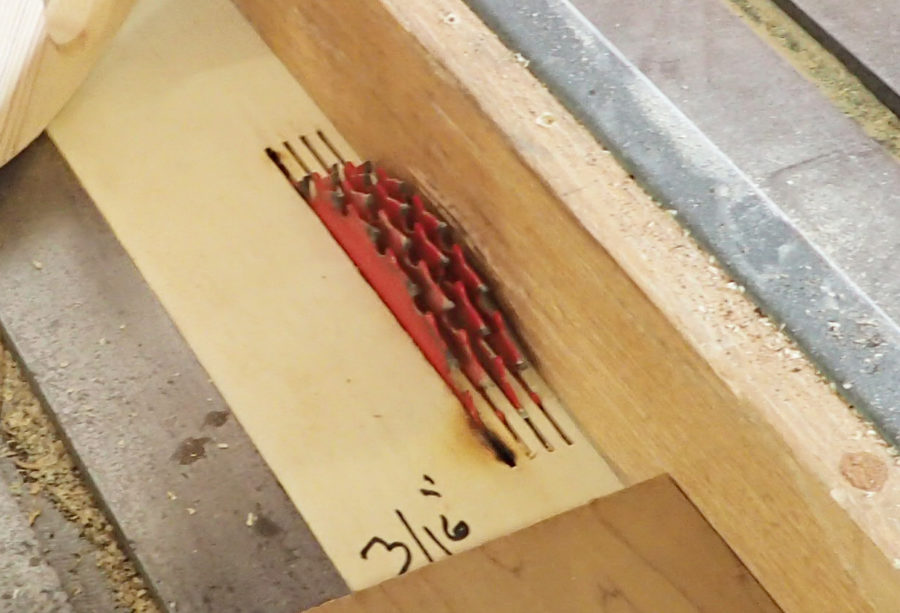

I got acquainted with stropping with these four strops. From the bottom, a large paddle strop with no compound, a medium paddle with white compound on the flesh side and green on the back, a small paddle made by Hutsuls with green and white compound. At the top a block strop with red rouge buffing compound on the grain side and emery on the flesh side

Blades are moved across the strop with the edge trailing, or, if you’re working with a large blade that’s better worked while stationary, the strop is pushed away from the edge. To do an initial stropping of a stone-sharpened blade, I start with the flesh side, charged with white compound, and do 30 strokes on one side of the blade, then 30 strokes on the other, then repeat the process on the grain side with the green compound. It is important to use a light touch and let the compound do the work. The leather is soft enough to make the surfaces of the micro-bevel along the edge slightly convex, making the edge stronger. Pressing the blade against the leather will exaggerate the effect, blunting the edge.

Small blades can be worked on the strop. This nata is being gently pulled from left to right, away from the cutting edge.

The work the strop does is right along the cutting edge, so you use the same angle as you would for the micro-bevels when finishing work with a stone. If you need a clear indication of where the strop is making contact, color the edge with a black permanent marker. The strop will uncover bright steel and alcohol will clean up the remaining dye when you’ve finished.

Stropping this large nata was easier moving the strop over the edge; it is being pushed to slide past the cutting edge.

The compound will turn black with the fine particles of steel it removes from the edge. It will continue to work through many sharpenings before it needs to be recharged. When the accumulation of compound needs to be removed, it can be scraped off. Alcohol works too, but may not be good for the leather. For scraping, I use a new replacement blade for a utility knife, held square across the strop and perpendicular to it.

One test of a sharp edge is slicing into the edge of a piece of paper. Stropping brought this axe up to the challenge.

A good test of a truly sharp blade is holding the edge of a piece of paper in one hand and slicing into it with the blade with the other hand. A sharp edge will slice cleanly through. An edge that needs more work will leave a fuzzy edge, tear the paper, or not cut into it at all. A really sharp edge will shave arm hair.

I did two trials with power stropping, one with a leather belt on a benchtop belt sander and the other with a 1″-thick wheel I made from eight layers of vegetable-tanned leather and mounted on a motor I use for a cotton buffing wheel. While both could bring a blade up to sharpness for the paper-cutting test, neither made the blade sharp enough to shave arm hair. That required finishing the edge with the handheld paddle strops.

A leather belt for my Harbor Freight 1 x 30 sander, charged with green compound, does a quick job of honing blades, but didn’t get them quite as sharp.

I glued circles of leather together with contact cement to make a 1″ stropping wheel. The edge of the wheel seems quite hard in comparison to the flat leather faces on my handheld strops. And the high speed didn’t seem to be a quick way to a sharp edge.

Leather strops and compound are now part of the sharpening arsenal in my shop and the system has helped me redefine what a sharp edge is. My woodworking is much the better for it.![]()

Christopher Cunningham is the editor of Small Boats Magazine.

You can share your tips and tricks of the trade with other Small Boats Magazine readers by sending us an email.

Jögge Sundquist uses Autosol for honing compound: watch his video.