Nelson Zimmer was born in 1922 and by the time he died in 2007, it is thought that he had produced some 500 designs, some of them while working for companies such as Chris-Craft and Toledo Ship Building. In 2018, Zimmer’s Utility Launch caught the attention of Peter Green, then an amateur boatbuilder originally from Ilfracombe in North Devon, England. Peter spent much of his career working in the oil and gas industry all over the world, and while he was based in the U.S., he built a Caledonia yawl. When the time came to move back to the U.K., he sold the boat rather than face the difficulties of shipping it. With a view to building another boat at some point in the future, he perused the designs in Fifty Wooden Boats, published by WoodenBoat. When he found the Zimmer Utility Launch, he immediately bought the plans.

Photographs by the author

Photographs by the authorDesigner Zimmer writes “Since this little launch is only 20′ long on the waterline, it cannot be pushed much beyond seven statute miles per hour, after which she will leave her stern wave behind and begin to squat, to the detriment of increased speed.”

According to Fifty Wooden Boats, Zimmer’s inspiration “came from the many slim handsome launches and cruisers that silently and gracefully passed by his waterside home following the First World War.” He designed his Utility Launch to transport passengers and supplies between towns and remote fishing camps in Canada’s North Woods. It had to be seaworthy enough to deal with the chop it might encounter when crossing large lakes but didn’t have to do so at any great speed. “So, they needed a pretty decent cockpit for six to eight people and some supplies,” said Peter, “and then occasionally, I guess, two people would end up sleeping on board, so there was a cabin with a couple of bunks and a bit of indoor storage for anything that needed to be kept out of the weather.”

Although Peter had never really been into motorboats, he was sensitive to the fact that his wife had “gone off sailing totally,” and he thought that this sort of boat would be the only way to get her afloat. And he very much liked the look of the design.

He was thinking of it as a long-term project and so when, after retirement, he enrolled in the 40-week course at the Boat Building Academy at Lyme Regis, U.K., he had no expectation to build the launch there as he knew it was a fair bit bigger and more complex than the boats that the BBA normally produces. So, Peter was pleasantly surprised by the positive attitude of the academy’s staff; the Zimmer launch would be one of the six boats to be built by the 18 students enrolled in the 2021 40-week boatbuilding course.

Zimmer designed the launch with “an able hull, one which could cope with the chop from a fresh breeze or glide silently through the water to avoid disturbing the fishing grounds.”

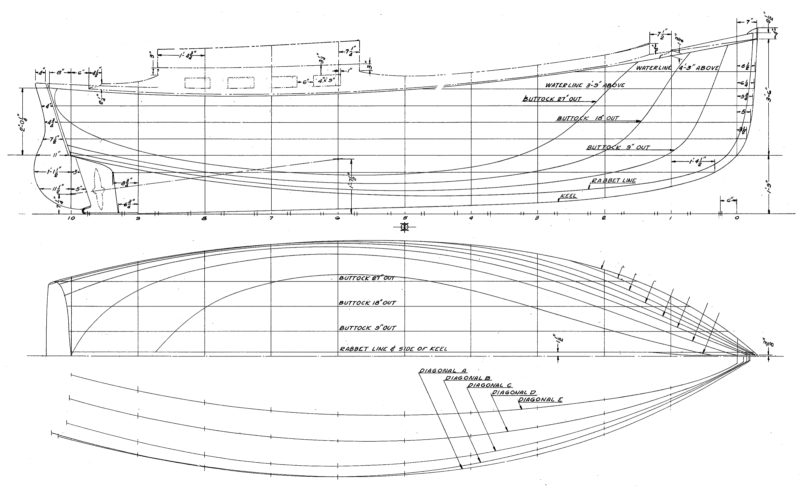

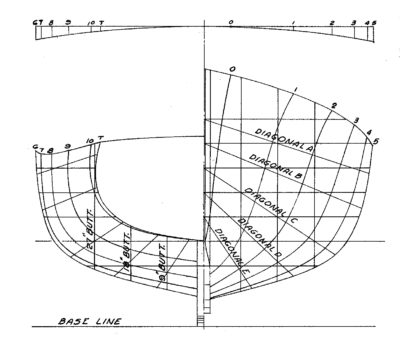

The four sheets of plans for the Utility Launch include a table of offsets, lines and construction drawings, and details for the steering and throttle hardware. The original construction is for 5/8″ cedar or mahogany carvel planking on steamed 1″ × 7/8″ white-oak frames. The hull is also well suited to the strip-planking method Peter preferred as well as cold-molding.

Starting with the table of offsets, a full lofting process was carried out. Eleven molds at 2′ spacings were called for, but it was decided to add two intermediate molds at the bow to give one-foot spacing to ensure fairness there.

The molds were set up upside down and construction began. The plans call for a backbone of 3″-sided timbers, but the BBA launch had a sapele centerline that consisted of a keel batten made up of two 1/2″- thick laminations with an additional 1″ thickness over the aft 3′, and an inner stem made up of thirty 3/32″ laminations. The slightly angled 3/4″ transom—batten-seamed oak in the drawings, plywood in the BBA launch—was fitted with sapele fashion pieces around its inside perimeter. Then the 3/4″-thick bead-and-cove Alaska yellow cedar planking was laid around the molds, starting at, and parallel with, the sheer and working up over the bilge, letting it run out naturally over the hog and stem. None of the planks had to be steamed. The outside of the hull was then faired before two layers of biaxial cloth were applied with WEST System epoxy resin.

The outside of the transom was veneered with sapele, and the exterior centerline components were fitted. The outer stem has the same make-up as the inner stem, while the keel and deadwood were made up from pieces of solid sapele. Twin pieces of timber were fitted to leave a ¾″ square hole that would be a starting point for boring the larger round hole for the stern tube. Cheeks paralleling the hole on the outside strengthen the deadwood there. After further fairing, bilge keels—about 5′ long and a maximum of 5″ deep—were fitted. These were not called for in the plans, but Peter wanted to make sure the boat could take the ground satisfactorily.

The plans call for 1 ¾″-thick oak engine beds to support a Norwegian-built single-cylinder Sabb HG diesel of 6- to 8-hp. The floors supporting the engine beds are 1-1/2″ thick, while the rest are 1″ thick.

The helm is well forward in the cockpit, leaving plenty of room for passengers. Zimmer’s plans include a cockpit covering and he suggested “with the mellon hood indicated on the drawings and some camping equipment she can even double as an overnight cruiser.”

Zimmer drew the deck with 3/4″ × 1-1/2″ pine on white oak deckbeams. All of the BBA launch’s deck structure is sapele. The 1-1/2″ × 2-1/2″ sheer clamp was tapered slightly toward the ends and was glued and screwed to the inside of the hull. In the plans, it is fitted to the inside faces of the timbers. The forward cockpit bulkhead is 1/2″ plywood clad in 3/8″ painted sapele to give the tongue-and-groove effect of the 3/4″ V-groove staving the plans called for. Four beams support the foredeck and three support the aft deck. Carlins were jointed into the forward cockpit bulkhead and the next deckbeam forward, and into two deckbeams aft. A subdeck of two layers of 1/4″ plywood followed.

The plans specified a coaming of 5/8″-thick oak, presumably steam-bent around the forward end of the cockpit. Sapele was used at BBA and the curved section was achieved—without steam—with six laminations. Some 3/8″ iroko was used instead of oak for the covering board and for the straight laid decks, originally specified for pine. The 2″ x 1″ rubrail—iroko, opted for in lieu of oak with a metal half oval—had to be steamed over about 5′ of its length forward.

The coach-roof beams are made up of six laminations of sapele, giving a molded depth of 1-1/2″; two layers of 3/8″ plywood were laid over them, and then sheathed with ’glass and epoxy. It’s a more contemporary approach than Zimmer’s tongue-and-groove staving covered with canvas.

The design shows a pair of double-hinged cabin doors to give a particularly wide opening of about 55″ through the forward cabin bulkhead, but with a sliding hatch of the more conventional width of 26″. However, as there were no details showing how this might be constructed while keeping it structurally sound, it was decided to fit a pair of single-hinged doors with the overall width of 39″ for both hatch and doors.

The cuddy was designed not as a cabin but as a place to stow gear and take temporary shelter from a spell of wet or cold weather.

Inside the cabin there are two settees/berths, though their use as seats will be severely restricted by the engine. Zimmer provided footwells only 10″ wide on either side of the engine, and the engine Peter bought for the boat afforded even less room. Peter decided to position the settees farther forward and added trotter boxes in the cockpit to maintain their length for use as berths. Mini bulkheads at the settees’ after ends serve as backrests for sitting while facing forward and create storage space aft.

In the cockpit, the sole was made of iroko instead of pine as indicated in the drawings, and fitted 4″ lower than designed, because Peter felt it would otherwise be too high; and 3/8″ sapele ceiling strips were fitted on non-structural laminated ground timbers glued to the inside of the hull.

Instead of installing the Sabb HG single-cylinder diesel engine called for, Peter found a used Yanmar 2YM 15 two-cylinder diesel with just 44 hours for a good price. He also found a second-hand 16″ three-blade propeller to take the place of the 15″ prop drawn in the plans. The design also specified a pair of cylindrical 12-gallon fuel tanks under the side seats in the cockpit, but Peter has fitted a single 16-gallon plastic tank made by Vetus under the foredeck. The transom-hung rudder is controlled by a steering system which has three-and-a-quarter turns from hard-over to hard-over.

The rudder has a brass pipe for a tiller. It runs through a slot in the transom and is covered by the deck. A line attached to the tiller runs around the perimeter of the boat and takes several turns around a drum connected to the wheel.

After Peter’s launch, MON AMI, was completed, he and a couple of other BBA students took her to her new home in Plymouth, a sea voyage of around 70 nautical miles. He told me that the sea was “mostly like a mill pond but a bit lumpy round Start Point,” the southern tip of Devon, and that the boat behaved very well. This bodes well for his plans to occasionally take her to open sea in the vicinity south of Plymouth Sound. He mostly intends to explore the extensive but more sheltered bays and tributaries around Plymouth, where he and his wife will use her for anchoring, picnicking, and swimming, with the occasional night on board.

I joined him on a calm but cold day for a short trip. MON AMI’s top speed at her maximum rpm of 3,600 is about 6.75 knots. Her stern squats significantly then, but Peter says he won’t often exceed 2,800 rpm. That gives her a speed of 6 knots and a fuel consumption that he thinks will be about 0.8 gallons per hour. At the tickover speed of 900 rpm she does about 1.8 knots.

Peter hasn’t had a chance to weigh his boat, but she is definitely lighter than a carvel version with a Sabb engine would be. She floats high on the designed lines and feels a little tender, so he plans to add some internal ballast—a little at a time until she feels right. It seemed a little strange, at first, steering from so far forward, but I soon got used to it and the view looking forward could hardly have been more unobstructed. I asked Peter if he had felt vulnerable to spray in a chop, but with the rising sheer and flared bow sections, he said that hasn’t been a problem. The Zimmer plans show a spray hood at the forward end of the cockpit, and an overhead cover for the whole of the cockpit; Peter might add the spray hood, although it would certainly restrict visibility from the helm.

It is easy to imagine that the cabin will be very cozy for sitting and sleeping when lying peacefully at anchor, but with the engine noise while underway it could only really be thought of as somewhere to shelter in wet weather.

Nelson Zimmer, apparently, envisioned that the Utility Launch would be a “good, common-sense little boat,” and MON AMI certainly does seem to be just that.![]()

Nigel Sharp is a lifelong sailor and a freelance marine writer and photographer. He spent 35 years in managerial roles in the boat building and repair industry, and has logged thousands of miles in boats big and small, from dinghies to schooners.

Utility Launch Particulars

[table]

LOA/ 21′ 3″

Beam/ 7′ 0″

Draft/ 1′ 7″

Displacement/ 3,467 lbs.

Power/ 6- to 8-hp diesel.

Crew/ 2 people cruising or 6-8 people day running.

[/table]

Plans for the Utility Launch come in four sheets and are available from The WoodenBoat Store for $105.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us!

What a beauty! Would love to build one of these with electric power and a bit more height in the cabin

Stephan, electrical power would be a great option assuming you can resolve charging issues. It would gain a lot of cabin space currently taken up by the Yanmar diesel.

We looked at various options to improve headroom whilst not spoiling the lovely low coach roof lines. Final approach was to raise the roof very slightly and lower the bunk level. That has just allowed sitting headroom, but it’s tight.

I purchased the plans from Nelson Zimmer in the mid to late 1980s, as I recall. After the arrival of the plans, there were a few letters back ‘n forth with Mr. Zimmer discussing various questions and specifically a bill of materials so I could estimate the cost of construction. Never did build the boat but cherish the letters from him to this day.

What a beautiful and purposeful compact boat she is, and I particularly like the forward controls.

With a Lenihan Charcoal Heater, that tiny cabin would make a comfortable spot for winter camping.

I’d recommend not using a charcoal heater. Carbon monoxide is deadly.