The summer high-pressure systems that bring sunny days to the Salish Sea are known for their accompanying lack of winds. After cruising British Columbia’s Discovery Islands in a small sailboat, I decided I’d enjoy the area more aboard a small motorboat, one that I could use to poke and prod my way along the meandering coastline, tucking into the small bays along the way.

I began a search for a suitable small motorboat to build. I studied the offerings from local designers who knew my local waters, but ultimately settled on a boat by Harry Bryan, a boatbuilder/designer based on Canada’s opposite coast. In 1998, he envisioned an update to the deep-V inboard-powered boats William Hand developed from 1900 to 1920. “The hulls Hand developed,” Harry writes, “do not skip along the surface of the water like fully planning boats. They will, however knife through the water at well over displacement speeds. Hand commented that he could recommend these boats without reservation as wholesome, steady, fine little sea-boats capable of really surprising speed.” Harry wanted to combine the advantages of the deep-V hulls with the clean and efficient four-stroke outboards, which were emerging at the time he was studying Hand’s work. Harry’s design was the Handy Billy 21.

I was sold on the boat’s classic lines, and its construction seemed to be within my abilities and budget. Fortunately for me, WoodenBoat ran a series of articles in 2001 on how to build the 21′ Handy Billy in issues 159 through 161, and I used them as my guide. At 21′, the boat is very close to the dimensions of a typical garage. I had enough room for it, but if a smaller Handy Billy is a better fit for the workplace you have available, Harry offers an 18′ version.

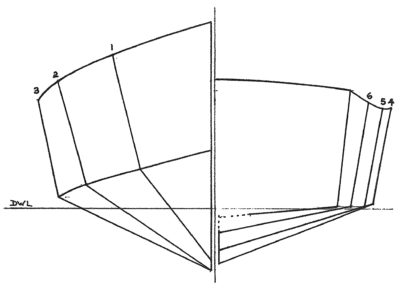

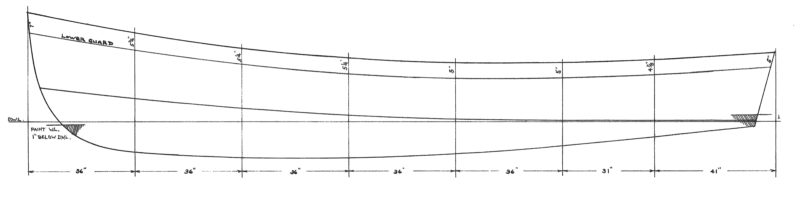

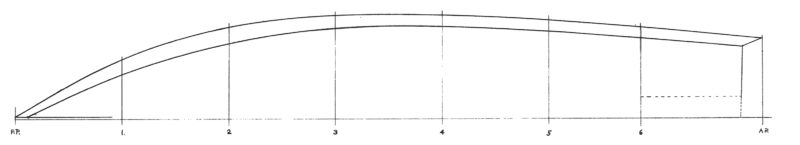

The Handy Billy’s long, lean, semi-displacement hull would marry well with Harry’s intention to use a modest outboard, just 25 hp, with electric start. His plans include three sheets of drawings—lines and offsets, construction details, and miscellaneous details—and a 21-page booklet. The plans detail batten-seam construction with 5/8″ cedar planking on oak framing. The outboard is enclosed in a covered well, so the boat can move along quietly and with little disturbance to the environment or the crew.

Photographs by and courtesy of the author

Photographs by and courtesy of the authorThe Handy Billy was designed for batten-seam construction and the battens would be let into the frames. The author opted for cold-molding, which didn’t require the battens.

Harry’s website designates this build as best for someone having intermediate skills. It is helpful to have some skills in woodworking (cutting, fitting, and shaping) and problem-solving, but having good work habits and a capacity for project management and planning will also really pay off. For anyone new to boat construction who is contemplating this design, it would be worthwhile to attend a workshop course and/or study many of the great books on construction. An intermediate project like the Handy Billy is mostly about having the perseverance that it takes to learn and to see the project to the end.

Building on my experience gained from constructing a plywood flat-bottomed sailing skiff, I waded in guided by the three WoodenBoat articles. They seemed to cover most, if not all, aspects of the procedures. Construction went as I had imagined with only a few difficulties. I did not have an easy time bending the single-piece sheer clamps into place as they wanted to split. Eventually, I did get them to fit. Today I would laminate the sheer clamp in place using more easily bent pieces.

The batten-seam construction would have three planks above the chine and four below. Like the William Hand boats that were its inspiration, the Handy Billy has a high and fine entry that will cut through chop.

While the framework is designed for batten-seam construction, Harry offers a single-sheet drawing by Doug Hylan for plywood construction. Harry’s website also notes the hull can be strip-built, but there are no instructions for that method. I went with cold-molding the hull; as with plywood construction, it eliminated the need for the seam battens in the framework. I applied 1/4″ x 3″ western red cedar in three layers with the outer layers laid fore-and-aft sandwiching a middle diagonal layer. The exterior has 6-oz fiberglass set in epoxy.

Harry writes in the Handy Billy booklet: “Motor boats have always carried with them the burden of noise.” He addresses the problem “by placing the engine within the hull and adding a barrier of acoustic insulation. The result is probably the most quiet outboard boat on the market.” To make sure the motor you’ll use with the boat will fit its housing, Harry notes that it is advisable to have it on hand in case you need to modify the well and engine box to provide full range of motion for the outboard.

The Handy Billy weighs around 1,300 lbs; an electric winch and guides on the trailer simplify launching and retrieval.

Towing the 1,300-lb boat and its trailer may require an SUV or a pickup truck. Launching at the ramp is straightforward. I have a 2,000-lb single-speed winch that is adequate for hauling out. Trailer guides have proven their worth to me while loading and unloading such a heavy boat by myself.

There is adequate room around the center console for passengers to move safely about the boat. Just below the aft end of the foredeck is the opening for the shelf that holds the fuel tank.

The cockpit is 13′ x 5′ and has enough space to move around while tending docklines and attaching fenders. It is deep enough to give you the feeling of being inside rather than on top of the boat. The center console gives the skipper an unobstructed 360-degree view and has room for instrumentation, binoculars, sunscreen, sunglasses, and other items. Forward of the helm there is a thwart with room for extra clothes in dry bags. In front of the engine compartment there is a bench seat with a fold-down backrest that gives access to two small storage compartments that are approximately 15″ x 15″ x 24″ deep on either side of the motorwell. There’s plenty of room to stow fenders under the rear bench. Beneath the foredeck, the Handy Billy has a shelf for the fuel tank and another above it for a fire extinguisher, spare ropes, and other items. I recently refitted the gas tank shelf with a sliding shelf to allow for easier access when refueling. The boathook and spare paddle are hung on hooks fastened to the inside of the frames. Flotation is not mentioned in the plans, but it could be put forward under the deck and in the rear compartments alongside the engine if desired.

The cutout for the motorwell is the only visible sign that the Handy Billy has an outboard motor for power. The large hatch on the back deck provides easy access to it.

I went with a 20-hp four-stroke motor, but on many occasions, especially with guests aboard, wish that I’d stayed with the 25-hp suggested in the Handy Billy instructions. The trade-off would be a marginal increase in gas consumption, but it would be worth the increased speed and power. With the 20-hp motor, the boat does get up to a top speed of 17 knots in a steady and gentle manner. The boat slices through the chop and is dry in all but the most extreme conditions, the ride is smooth and comfortable, cornering is steady and predictable, and the boat is easy to maneuver in tight spots and while docking. Passengers ride on the forward bench which trims the boat nicely and allows for easy conversation during all but the highest speeds. I have confidence in the Handy Billy’s abilities to handle moderate conditions on lakes and other protected waters.

The Handy Billy was not an overly difficult project, but it did come with a steep learning curve. In my 20 years with the boat, I have gained many skills as a builder and owner. Today, I use it for video recording, work for which the boat is very well suited. It would make a fine addition to a lakeside cottage as a runabout for fishing or transporting in style. It’s a charming boat that continues to resonate with admirers wherever she goes. ![]()

Steve Cormack is a self-taught amateur builder with a workshop in Pender Harbor, British Columbia. He started building boats nearly 40 years ago and has completed several small plywood kayaks and strip canoes. In addition to the Handy Billy, he has built two sailboats: a Selway Fisher Ptarmigan pocket cruiser and a Blackswan 22 for cruising. He is currently finishing a 32′ Lake Union–style dreamboat based on a Katherine 30, designed by William Hand Jr.

Handy Billy 21 Particulars

[table]

Length/21′

Beam/5′10″

Weight/ approx. 1,300 lbs

Capacity/1 to 8

Propulsion/ 8–15-hp outboard for displacement speeds, 25 hp for planing

[/table]

Plans for the Handy Billy 21 are available through Bryan Boatbuilding for CAD $80. Plans for the Handy Billy 18 are available for CAD $80. A single sheet of information for plywood construction for both versions is available for CAD $25.

Plans for the Handy Billy 21 are available through Bryan Boatbuilding for CAD $80. Plans for the Handy Billy 18 are available for CAD $80. A single sheet of information for plywood construction for both versions is available for CAD $25.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us!

Beautiful boat

Thank you very much. We’ve enjoyed many hours on the boat and look forward to many more. As I said in the article, the boat attracts a lot of attention wherever she goes.

Mr. Cormack,

That’s a beautiful boat! The helm seat catches my eye. I don’t think Harry’s plans show that seat. You wouldn’t have any details of your seat design that you would be willing to share, would you?

Thanks for the article.

Ted

Hi Ted,

I made that helm station as a one-piece console-and-seat unit which gives a bit (4”) raised platform between the two. I went with an Adirondack-style seat, which is fixed in place. I would suggest using a store-bought pedestal that would give you more seating positions. Hope this helps.

Thanks for the reply. I’m sure you are right about the practicality of the store-bought pedestal with more seating positions, but you can’t beat the aesthetics of your choice.

Thanks again!

Ted

Spent well over 20 years sailing the Inside Passage, Skagway to Seattle, on Alaska state ferries, as both passenger and crew. The beauty may be unmatched.

Sail or engine, this is a dream, and an ideal boat to realize that dream.

How does that Wind in the Willows quotation go: “…there is nothing—absolutely nothing—half so much worth doing as simply messing about in boats.”