When my wife wrote “Love it!” on the study plans for Ken Bassett’s 18′ Firefly, a performance rowing boat, it seemed I had the green light to build it. My boats had already filled the garage, barn, crawl space, and shed, and my wife, being more reasonable than passionate about my boatbuilding, drew the line at eight boats. When she began to get interested in rowing and having a rowing boat for herself, it became my opportunity to build another boat.

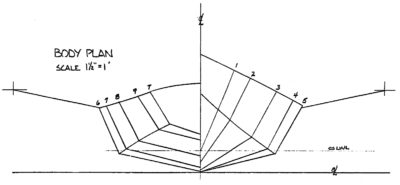

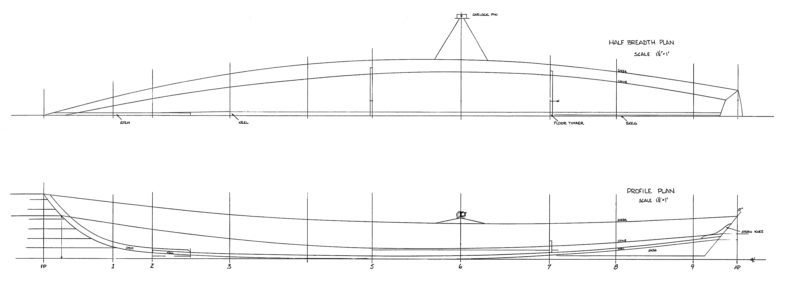

The Firefly, 18′ overall, has a waterline length of around 16′ for performance rowing. Its beam of 34″ means it can easily balance itself without the need for oars to be in the water. The low 7″ of freeboard would present a small profile to the wind, and the long chines and skeg would give it good directional stability. The Firefly has all the attributes for a fast boat appropriate for novices focusing on rowing for exercise or sport. The panel-on-frame construction lends itself to backyard boatbuilding, and the low count of individual parts signals a reasonably quick construction.

I ordered the plans from The WoodenBoat Store. They consist of five sheets of drawings: profile and inboard arrangement; lines, offsets and construction, and rigger details; sliding-seat mechanism, full-sized mold patterns, stem and keel details; and transom pattern, construction sequence, transom dolly, and keel details.

Photographs by the author

Photographs by the authorThe plans include drawings for a sliding seat and outriggers, but a drop-in rowing unit, like the Piantedosi Row Wing here, is a ready-made option. The bare hull, weighing about 85 lbs, can be cartopped, but with a small, lightweight aluminum trailer the heavy lifting can be avoided.

I got to work setting up a strongback and cutting out the molds. The full-sized mold patterns eliminate the need for any lofting. The hull frame is very simple in construction: a laminated stem, a keel, two chines, two laminated frames, a transom, and a knee. The frame is covered by bottom and side panels cut from 6mm marine plywood. A skeg, breasthook, knees, and gunwale complete the hull. I chose Aquatek’s meranti plywood for the panels, spruce for the frame, and local black walnut for the transom, knees, breasthook, and gunwales.

The chine makes a sweeping curve that starts at the stem, drops just below the waterline amidships, and ends at the transom. As the beauty of the boat lies in that line and the sheer, I wanted those chines to be very crisp and fair. The joint of the sheer panel and the bottom panel would have to join in a perfectly smooth, unwavering sweep for about 17′. I knew from experience as the chines get beveled, the pencil-drawn centerline that defines the sweep would get planed away and be tedious to reestablish. I needed a better way.

The 34″ beam provides good stability for getting aboard from either a beach or a dock.

To make a lasting centerline in the chine, I routed a 1/4″ groove about 3/8″ deep down the center of the outer face of each log. I then mounted the chine logs into the molds and planed them to create the bevels for the bottom and side panels. There was enough of each groove left to glue a 1/4″ × 1/2″ wood spline into it. The spline perfectly defined an accurate curve of the chine. Then, rather than butt the planking panels to each other, I butted them to the spline. With the spline carefully planed flush with the plywood, voilà, a perfect chine!

I sheathed the hull in 6-oz fiberglass cloth set in epoxy. After painting, the bare hull came in around 85 lbs. Although I didn’t keep track of time, I would estimate it took 150 hours of off-and-on evenings and weekends work to complete.

The plans detail a sliding-seat setup made of cherry wood and riggers constructed from 3/8″ stainless-steel tubing. Rather than fabricate all that, I chose to purchase a Piantedosi drop-in rowing frame. I thought the off-the-shelf solution would probably be cheaper than finding a metal shop to fabricate and weld the tubing, and I’d eliminate the time making the sliding-seat system.

At the catch, with the rower’s weight at the aft end of the slide, the transom just kisses the water.

At the finish, the bow supports the rower’s weight at the forward end of the slide without the hull going out of trim.

I mounted the rowing frame so that it could be easily detached from the two ribs. Separated, it would fit in the pickup bed and I could hoist the boat, right-side up, onto the boat rack above. With ratcheting tie-down straps and some auxiliary foam wedged around the shallow V-bottom, the boat rode secure. Although the plans detail a transom dolly for moving the boat around inverted, I simply shouldered the hull to the water and then attached the rowing frame to it. Eventually this car-topping approach got awkward, and I purchased a lightweight aluminum trailer to make a simple package for towing and hand launching off the beach.

Getting into the boat off a beach is simply a matter of floating the boat, reaching for the opposite gunwale, and hopping in. The boat keeps its balance while you grasp the oars and get adjusted. No need to rush. Getting off a dock is another matter. The rigger not only positions the boat 14″ away from the dock, but it can also wedge itself into the dock structure in a variety of ways and be quite a nuisance. Attention is necessary to ensure that the boat is not trapped by the rigger. One can step onto the bottom panel and once aboard, the boat balances itself and is as stable as a canoe.

On the water two pulls at the oars brings the Firefly up to speed. That is once you clear the dock or the beach shallows. The 298cm recreational sculls recommended in the plans (racing oars are measured in centimeters, 298cm is 9′ 9-1/4″) and 62″ outrigger spread are amazingly awkward in tight situations. Since the boat has good stability without relying on the oars, I sometimes use a kayak paddle as auxiliary propulsion to help maneuver in and out of tight spots to avoid using the oars.

The boat cruises easily at 4-plus mph, demanding no more effort than a brisk walk, and is surprisingly seaworthy. Once caught out in 1′ to 3′ waves by a sudden change in the weather, the boat found its way through the chop without shipping water. It stays where you point it; it takes a bit of coaxing on the appropriate oar to change direction. Underway, the boat feels fast and nimble, comfortable and stable.

I had no experience in performance rowing and at the time knew no one who had, so I set up the rowing frame according to Piantedosi’s directions. The first few rows were frustratingly awkward and brief, but there were one or two brief moments when it all came together and the boat flew along the water with such grace and ease that it seemed effortless to propel it. I felt a spiritual lift and delight and I had to have more of that. Those brief moments were enough to keep me engaged as I made guesses as to what were issues with the boat, rowing frame, or me. Over time, by trial and error and with incremental adjustments, the Firefly became comfortable for me to row. During the winter, workouts on the gym rowing machine got me in better physical condition. Some coaching tips from an experienced rower got me to the point where I could put miles on the boat.

The drop-in unit has a span of 62 1/2″, just 1/2″ greater than the outriggers drawn in the plans. The sculls used with the Firefly are between 9′ 6″ and 9′ 9″ in length.

The Firefly started out as a boat for my wife, but in the prolonged tune-up phase, I monopolized the boat to make the setup work for my tall stature. I thought I could dial it in for her smaller size, but after seeing me get used to rowing the boat, she was reluctant to take on the learning curve I went through. Casual rowing with a fixed seat and drifting were more to her liking. She’s now talking about a St. Lawrence Skiff, a boat more like what she had in mind from the beginning. No problem, it’s another opportunity for me to build a boat!

Coming from a boating background where each of my boats had multiple uses, it took time to recognize that the Firefly is a thoroughbred: it does only one thing and does it exceptionally well. It is meant to fly across the water in light wave conditions with grace and ease. It has the speed to put the miles behind without exhaustive effort, and when it’s time to rest one can drop the oars, unpack a snack, and comfortably drift while watching the scenery. Back at the beach or ramp the boat’s good looks draw comments from the passersby. The boat’s simple construction will get you on the water quickly and introduce you to lively, nimble performance. I’d call that joy. ![]()

Ed Neal of Cleveland, Ohio, started his interest in woodworking as an 11-year-old Boy Scout, whittling neckerchief slides. Twenty-something years ago he came back from a wilderness canoeing trip in Canada wishing to add an outrigger to the canoe for additional safety. He went to the downtown Cleveland Public Library looking for a book that might be helpful. There he fell down the boatbuilding hole and has yet to surface. He is now the executive director of the Cleveland Amateur Boatbuilding and Boating Society.

[table]

LOA/ 18′

Beam/ 2′ 10″

Draft/ 4″

Weight/ 90 lbs

[/table]

Plans for the Firefly are available from The WoodenBoat Store in print and digital format for $60.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us!

I built the Firefly and found it to be a great recreational rowing shell, but decided to improve on this design a little by slimming down the beam to 28″, using 4-mm ply, adding decks fore and aft with a reverse transom that keeps the length and adds a unique look to recreational rowing shells. It was a design that won ‘best maintained yacht’ at San Diego Yacht Club’s opening day event since they did not know how to otherwise rate it.

Now that would be something to see! Send a pix to [email protected].

Ed Neal, Cleveland Amateur Boatbuilding and Boating Society

Thanks for your article Ed. I enjoyed it and sent it on to the man who built the Firefly I have owned for over twenty years now. I use, it for more than just rowing. I’ve found it a very pleasant way to catch the odd fish in our river. Either by trolling, or stopping and casting. The stability is such that standing to fish is not an issue.

Like William, I have often thought about a new version. Maybe a couple of feet longer, lighter materials, even maybe dual rowing so my wife can come along.

Thanks again,

Dave

I find your method of making the chines intriguing. Obviously labor intensive, but the advantages for maintaining a precise chine profile should be very worthwhile.