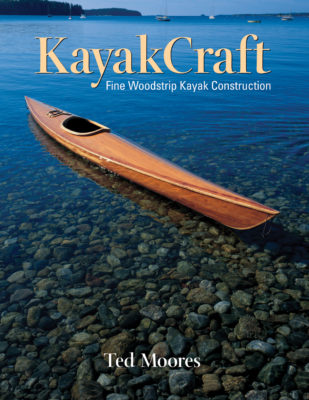

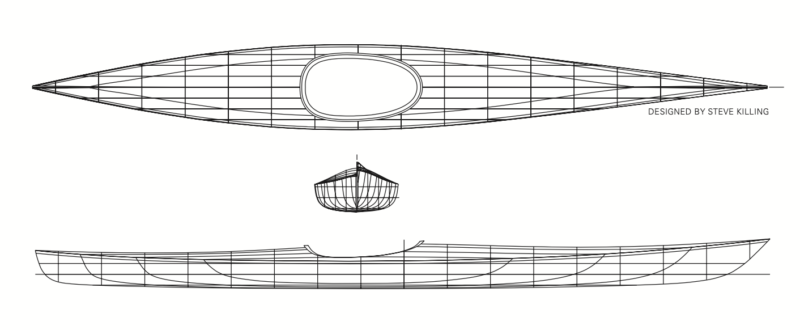

The Steve Killing–designed Endeavour 17, a kayak built of cedar strip planks and fiberglass, combines beauty, fast lines, load-carrying capacity, and relatively easy construction. Let’s have a look at each of these points—the last one, ease of construction, in some detail.

Photo by Darel Bridges

Photo by Darel BridgesThe Endeavour 17, a sea kayak built of cedar strip planking, fiberglass, and epoxy, is suitable for a wide range of paddlers. Sufficiently stable for a novice paddler, the boat also has performance characteristics to satisfy the more experienced. It’s a great kayak for skill development.

While the building of this boat has some challenging aspects, there’s nothing about it that should turn away a first-time boatbuilder possessing fundamental wood-working skills. Some processes — the bending and beveling of the stems, for example, or the trimming of the cockpit — might require the hand-holding of a good instructor, but we’re lucky in that regard: Ted Moores, one of the best builders of strip-planked small craft in North America, has written a book detailing the process of strip-kayak construction (KayakCraft, WoodenBoat Publications, 1999). The subject boat of that book is the Endeavour 17. (The book includes a gallery of designs, and all are of the Endeavour 17 family; the Endeavour is considered the patriarch.)

Construction, as with most (but not all) wooden boat building, begins with a series of molds that define the sectional shapes of the boat. These are set up at established intervals on a long, narrow table-like structure— a so-called “strongback.” The shapes of the molds can be determined by the laborious process of lofting—the drawing of the plans full-sized, from a set of numbers provided in Ted’s book. But we needn’t do that, for the plans include full-sized patterns. It’s best to use those, and to get on with the construction.

KayakCraft, by Ted Moores (WoodenBoat Publications, 1999), details the construction of a strip-planked sea kayak. The Endeavour 17 is the example used in the construction sequence, but several sister designs are also profiled in the book.

When it comes time to plank the boat, a first-time builder might find it best to purchase already-milled strips from one of several companies that specialize in producing these. Why? Because the milling of strips is a messy and mind-numbing job best left to shops equipped with power feeders, dust collection, and sharp power tools. Which isn’t to say that the home-based boatbuilder blessed with a good supply of rough-cut cedar should not do this. Rather, it’s to say that if he does, he should be prepared for a day or two of dust and noise and sweeping—not to mention a lot of pushing and feeding of stock through machines that require careful tuning.

One edge of each of the 1⁄ 4″ strips receives a concave profile (a “cove”), while the other receives a matching half round (a “bead.”) When these two profiles are put together, the result is a tight joint that can articulate around the sectional curve of the mold—sort of like a linear ball-and-socket joint. This eliminates the time-eating process of beveling the edges of the strips for a tight fit—something nobody in their right mind would do when building a boat like this. (Anymore. For that’s the way it was done in the early days of strip-planked canoes.)

The stems (the curved structural ends of the boat) are built from steam-bent laminates of ash or cherry. Steambending is often a daunting process to a first-timer, but it shouldn’t be. It’s fun. It’s easy. And with these small pieces, it can be accomplished with a stovetop teakettle and a rudimentary box. Ted Moores’s book will show you how.

The planked hull requires lots of sanding. Ted Moores has reduced this process to a series of steps which, if followed to the letter, will yield a flawless surface ready for fiberglass. A layer of ’glass on the inside and a layer on the outside completes the hull, though there’s still some filling and sanding to be done before varnish is applied.

The deck is built on a separate set of molds, in the same manner as the hull. When complete, this structure fits like the lid of a cookie jar onto the hull, and is glued in place, stiffening the whole considerably. Imagine a shoebox—a shoebox lacking a lid. Grab it in both hands and twist those ends in opposite directions. It’s flexible, isn’t it? Now put the lid on it. No more twist. The same mechanics apply to the Endeavour 17.

You can get fussy, or you can stay basic with the fitout of this boat. The choice depends both on your skill as a woodworker and on your intended use of the boat. If you’re a day paddler, you might not want to cut holes in the deck. If you’re going on an expedition, a couple of hatches, one forward and one aft, are in order. The average build time of an Endeavour 17 is about 150 hours. This varies, of course, depending on the builder’s skill and the boat’s level of detail.

Photo by Darel Bridges

Photo by Darel BridgesThe Endeavour can be configured for serious camping, with hatches in the forward and after decks.

The Endeavour is a good weekend expedition boat. Its payload range (paddler and gear) is 130 to 250 lbs, and its fine lines and stiff hull combine to make it a moderately fast boat. But is it durable? Yes, it is. Can you haul it up a sand beach and over rocks? No. Or, at least, you shouldn’t. There’s no doubt that one of the ubiquitous brightly-colored rotomolded plastic boats will serve a hardcore boat-dragger better than an Endeavour 17. But a kayak dolly, a strong back (not a strongback) or an extra set of hands will help to avoid such finish-marring behavior.

Is this boat heavy? Again, no. It weighs the same as an off-the-shelf fiberglass boat—perhaps just a little more. But for the title of this magazine, one might be tempted to describe the construction of an Endeavour as fiberglass with a cedar core. Cedar is a light wood. It is stiff and fatigue resistant, meaning you can bend it without weakening it. That’s not true of fiberglass alone, without a core. Bend that stuff a few times, and you’ve permanently weakened it. That’s the real beauty (besides the obvious eye-catching Beauty) of building a fiberglass-sheathed strip-planked boat. They’re durable. Wicked durable, the beach-dragging caveats above excepted. They’re stiff. And they’re a joy to look at.

The Endeavour 17 is among the best designs for strip-planked kayaks. If you’re an inexperienced paddler, it’s a boat to grow with: You won’t get bored with its performance as your skills develop. Ted Moores describes it as “mid-road between rock-solid platform for the beginner and a slim performance kayak.” He rightly says that “this hull suits just about everyone.”

The choice of kayak is quite personal: it depends on both the size and weight of the paddler, and the intended use of the boat. The Endeavour 17 fits a wide range of payloads and uses, but one of its sister designs, built using the same techniques as those employed in the Endeavour, may be better for some paddlers. Full-sized patterns for the construction molds are included in each plans package.

Plans for the Endeavour 17, and their companion book, KayakCraft, are available from The WoodenBoat Store.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us!

I have taken Ted Moores’ class at the WoodenBoat School in Maine and learned a great deal. Ted Moores walks on water and is a great human being. I have since built several Endeavor kayaks and have taught canoe- and kayak-building classes at North House Folk School in Grand Marais, Minnesota, for thirteen years. Cutting your own strips is easy if you have good in feed and out feed. Putting three thin-kerf blades on your arbor with spacers is the way to go when cutting your strips. You will not believe how easy it is and how the board you are cutting stays against the fence. Three strips cut on every pass. Putting bead and cove on your strips is highly overrated and a huge waste of time and wood. It is certainly not needed on the deck. Putting the bevel on few strips is easy with a small block plane or finger plane. Another set of forms for the deck is not needed. The instructions in Ted’s book, plus his videos, explain how the hull and the deck go together. The process is very strong and simple. If you want to build a strip canoe or kayak, go for it. If you can tie your shoes, you can build this kayak. Your first boat will take you 200 to 250 hours. Trust me. Thanks for letting me share my thoughts with you.

Best regards,

Ken Koscik

Monona, Wisconsin