I’ll put a case to you, as lawyer Jaggers did hypothetically to young Pip in Great Expectations. Put the case that a boat should be designed, and that this boat should be handy under oars. Put the case that this boat should also sail well, and further that it should accommodate a small outboard motor off the transom, should some unknown person desire to do so. Put the case, as well, that this boat must be detachable into two halves that may “nest” one inside the other so as to be hauled aboard and lashed down in the smallest possible space on the crowded deck of a long-distance cruiser, and therefore must be very light yet equally very strong. Put the case that this boat must also be attractive, and put that last case to yourself very carefully. These expectations are great, indeed.

Compromising to resolve such thorny conflicts is the intellectual challenge that Russell Brown, a designer and boatbuilder of Port Townsend, Washington, took on in working up a nesting dinghy that has one further twist: he wanted his company, PT Watercraft, to be able to market the boat as a kit that could be built by amateurs.

The result is impressive. Brown has been working a long time in lightweight boat construction, with an eye toward engineered solutions tending toward minimalism. Using thin plywood and powerful epoxy to best advantage, he strives for construction that is light in weight yet very strong, as many others have in using these techniques. He also spent a good part of his youth cruising the world’s oceans, first with his parents and later on his own, so he has direct practical experience of what works and what does not.

Tom Jackson

Tom JacksonBy extensive ocean cruising, Russell Brown came to know what he valued in a nesting dinghy, and his PT 11, which weighs just 85 lbs, balances conflicting purposes of sailing, rowing, light weight, and compact stowage while still remaining a handsome boat.

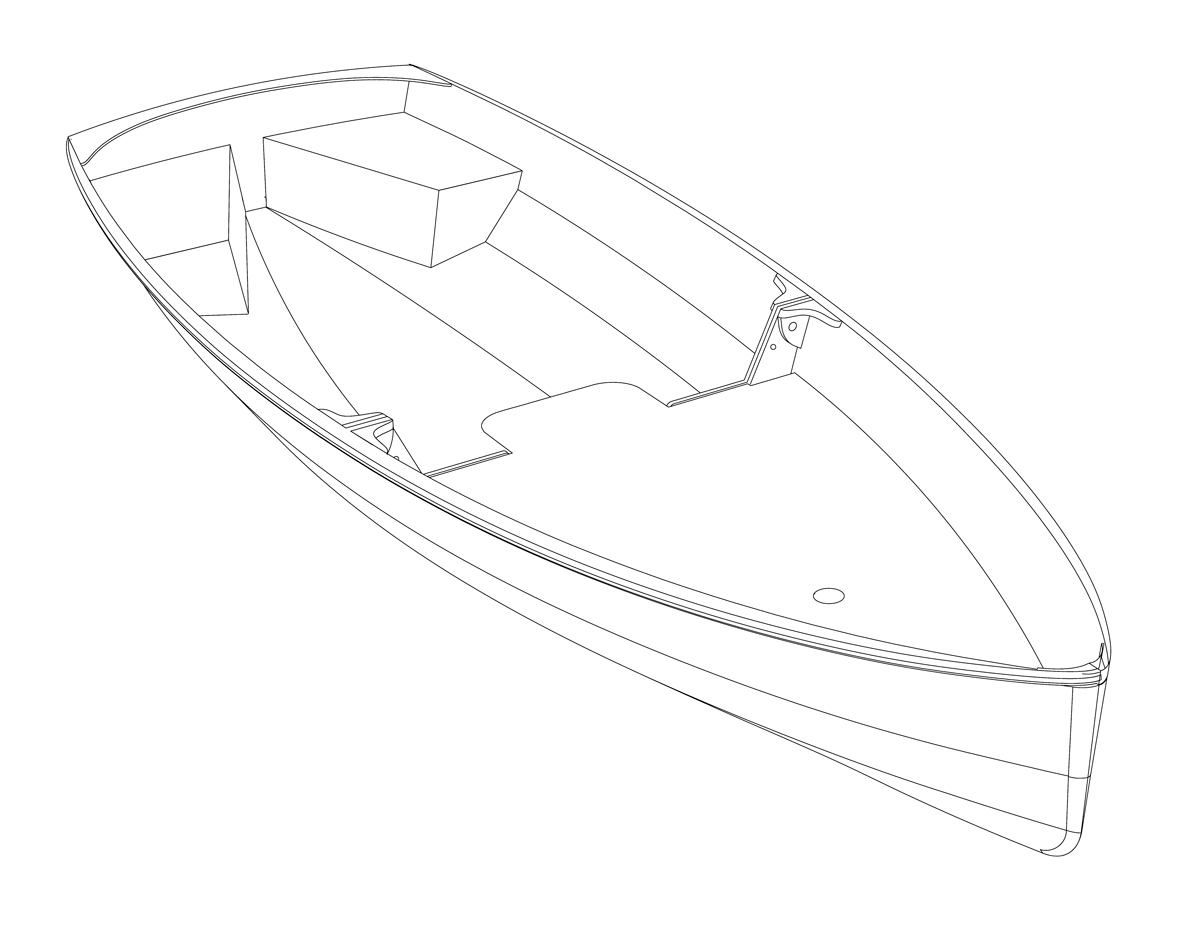

For light weight, Brown chose 6mm okoume plywood for the topsides and the bottom panel. Almost every part of the boat is made of plywood, sheathed in fiberglass cloth set in epoxy. Though 11′ long when joined, the hull weighs only 85 lbs. With its low weight, this boat’s halves can be manhandled ridiculously easily by two people, and probably very easily by a fit person working alone. To keep the dinghy to a minimum size for hauling aboard, Brown chose to make the hull flat-bottomed, with but slight rocker and a skeg of minimal depth. Plus, he made the boat’s profile very flat at the sheerline, that critically important curve formed by the top edge of the uppermost plank. Giving a boat a flat sheerline risks ungainly appearance, but to Brown it was imperative to do so to allow the boat to stay compact when nested on board: the bundle is only 5′ 10″ long and 1′ 8″ high at one end and 1′ 5″ high at the other, and more sheer would have made for a taller nested stack. Brown anticipates that most cruising sailors will lash down the boat under the swinging mainsail boom, so height is critical.

Brown developed custom stainless-steel hardware to join the two halves together, and the system seems to work well in the water or on land. In this type of boat, the hull is usually constructed in full, then two bulkheads are installed at or near amidships, and then the builder—no doubt after taking a deep breath—cuts his hull in half, a process fully described in the kit’s extensive instructions.

Tom Jackson

Tom JacksonThe 11’ hull divides to form a bundle only 5’10” long, 4′ 2″ wide, and a maximum of 1′ 8″ high, and the flat bottom makes nesting them easy.

The forward of the two sections is completely decked over at thwart height, which provides necessary hull stiffness and also sees to it that any water coming aboard is directed to the after section for easy bailing. At the top of the sheerstrakes, plywood pieces scarfed together and set perpendicular to the sheer planks make L-shaped gunwales that stiffen the topsides, deflect spray, and provide a flat surface to receive a glued-on continuous, low-profile rubber fender that actually accentuates the boat’s appearance. Brown kept his ’midships bulkheads low, so that the foredeck extends aft of the joined bulkheads when the hulls are assembled. This provides a comfortable rowing position, with no need for a thwart.

The joining hardware, meanwhile, consists of four knobs that screw through bushings in the after bulkhead and into threaded receivers in the forward one, with O-rings making the fittings waterproof. The sequence for attaching the hulls together is well thought out. The forward hull has two custom carbon-fiber brackets mounted on the deck and tight against the bulkhead sides. These brackets extend aft just far enough to have the after bulkhead slip behind them, which is easily managed. They hold the hulls together and in the right alignment while tightening first the lower knobs and then the upper ones. The hull halves join together surprisingly tightly, and in rowing and sailing (admittedly in light conditions) I never saw any water come through.

Tom Jackson

Tom JacksonThe two hull halves assemble easily while afloat.

Technology and innovations seem to have come together to make nesting dinghies more viable than ever. Lightweight plywood-epoxy construction makes a stiff hull, which is especially important when introducing the added complexity of cutting it in half. The challenge of lightweight structural design is what got Brown thinking about nesting dinghies in the first place. “A dinghy is really a tool, it’s not a pleasure boat. If you’re talking about a dinghy being a tender for a cruising boat, it has to be light, it has to be really tough, it has to be abrasion resistant, and it has to perform all the other functions it has to perform.

“The intent was to make a dinghy for serious cruisers,” Brown said. “I have a nesting dinghy that I built in ’85 that I took on most of the cruising I’ve ever done. It didn’t have the kind of sophisticated attachment hardware that this one does, but it’s what really got me into the whole idea of nesting dinghies. And cruising really led me to see the interest and need for a serious nesting dinghy. There’s more nesting dinghies out there than you can shake a stick at, but none of them that were ever really highly developed, as far as easy assembly in the water, light weight, complete kit package, good sailing characteristics, and really good rowing characteristics.”

Tom Jackson

Tom JacksonTwo carbon-fiber brackets (visible at the edge of the foredeck near the bulkheads) hold the hulls in alignment while knobs are tightened to hold them firmly together.

Brown started with pleasurable rowing in mind. He noticed other cruisers needlessly struggling with dinghies mainly because they were miserable to row, while his was comparatively easy. “That’s what I ended up doing with my nesting dinghy. I loved it. Other people had these god-awful inflatables, they were hoisting these 18-hp engines on and off, and going for gas all the time. It was my experience that got me going in this direction. This boat’s not a sprinter of a rowboat, but it really has very good cruising speed capabilities.” Brown earlier considered all-carbon-fiber construction for even lighter weight, but actually building a prototype gave him experience that came to the rescue: “I actually didn’t like it because it’s too loud. I don’t like rowing it, I don’t like using it. If you dropped the bow painter snaphook into the boat, the whole anchorage woke up.”

Tom Jackson

Tom JacksonComing onto a beach, the boat’s flat bottom, which is well sheathed in fiberglass cloth set in epoxy to resist abrasion, allows her to stand upright, and the long foredeck makes it easy to step ashore.

During my row, I found that the new boat, largely because of its light weight, feels a bit squirrelly at first, but in short order it’s very simple to find her sweet spot. The boat tracks well enough. The combination of light weight and slight rocker, or longitudinal curvature, to her flat-athwartships bottom, meanwhile, make her extremely maneuverable. She’ll turn with just a flick of the oar. That’s an excellent characteristic in a crowded harbor, where responsive turning and quick stops are often necessary. However, in my judgment she would be plenty able for gunkholing expeditions and amply commodious for ferrying supplies from shore. “We’ve rowed the boat with four 200-lb guys, and it still goes right along,” Brown said. I found her quite a pleasure to row; I could see Canada over my shoulder, and Brown coaxed me back to shore only with some difficulty.

Nosing into shore, the flat bottom proved its worth once more. The boat comes easily to the beach, and it stands upright prettily. The foredeck makes it exceptionally easy to step forward and out of the boat, dry-footed.

The sailing rig is deliberately simple, a modified windsurfer rig with the sail’s sleeve slipping over a two-part carbon-fiber mast, which needs no standing rigging. The mast itself fits easily into a tube mounted between the foredeck and the bottom. The entire rig weighs but a few pounds. Brown, who has long experience in developing foil sections in plywood, has also designed a daggerboard and a kick-up rudder, both of which would be very familiar to any dinghy racer. The designer likes to sit right on the boat’s bottom while sailing; in light air, I found kneeling amidships to work all right for me. It was a light-air day during our rendezvous, so I can’t say much about the boat’s sailing characteristics, though I found her quick for what little breeze we had. Heeling to the few puffs that materialized, she held out the promise of surprisingly good performance. Later, when Brown found a bit more breeze during his time at the helm, I observed that she accelerated quickly and tacked easily. Like any lightweight dinghy, she is very responsive to crew weight, yet she feels stable. An old dinghy racer would be at home here and would not be displeased by her sailing qualities.

Tom Jackson

Tom JacksonThe dinghy attains good speed quickly, tracks reasonably well, and rows very comfortably. Unlike many dinghies, she’ll make rowing ashore from an anchorage a pleasure.

As I sailed, in my imagination, I thought of anchoring down in some pretty harbor somewhere and spending the few minutes necessary to get the boat launched, rigged, and ready to sail into the golden light of evening. I put the case, further, that doing so would allow anyone so fortunate to enjoy such a harbor in a boat that is fine-looking beyond all expectations. ![]()

Russell Brown

Russell BrownTo keep the PT 11’s nested dimensions to a minimum, Brown made the boat flat-bottomed with only slight rocker and also quite flat-sheered. Nevertheless, the boat is handsome and sails smartly with her modified windsurfer rig. The boat is available in kit form only, and the designer has developed an extensive instruction manual for builders.

The PT 11 nesting dinghy is available as a kit from PT Watercraft.

I saw one of these at Russel Brown’s booth at a pre-pandemic Port Townsend Wooden Boat Festival. It was beautifully made, well thought out and totally impressive. Later I watched video of it sailing and my dinghy racing days came back in Technicolour. I am not a cruiser, but if I were I would make one of these boats. It would make your time in harbour so much more interesting and it would put a smile on the faces of many people anchored out. There would be envy.

My brother James M. Armstrong lives in Port Angeles, and is active in boating safety. I’m sure your activities are known to him. He’ll get a post on FB to see what he thinks!

Is the boat for sale? Are plans of this boat available?

I saw this when Leo was building the Tally Ho and wanting a yacht tender and was impressed. I really wish they would offer plans to build these instead of a full kit. I have built quite a few stich and glue and skin on frame boats over the years but have always found the kits to be overpriced. With the sail, the total rig comes close to $6k which is unaffordable for me.