Here we have an 18′ Hampton sloop, an evolution of a coastal workboat that developed for fishing in and around Hampton, New Hampshire, and spread far afield. The boatbuilding duo O’Donovan & Dole of Searsport, Maine, built the boat in these photos, modeling it on an original one built in the early 1900s.

Early Hampton boats were double-enders, and were common in New England beginning in the early 19th century. By the end of that century, transom sterns were more popular on this type, and motors eventually came to dominate them; the iconic Maine lobsterboat is likely an evolution of the type, as its bow profile and forward sections will attest. Hampton boats were carried on schooners and sold to ports as far away as Newfoundland and Labrador, where they were further developed as local types. The boats ranged in length from 16′ to 26′, and had a distinctive profile shape: a straight stem, a deep forefoot, a long, straight keel, and a generous sheerline. The boats were shapely in plan view, too, with hollow waterlines forward and aft.

Benjamin Mendlowitz

Benjamin MendlowitzJohn O’Donovan and Patrick Dole, doing business as O’Donovan & Dole in Searsport, Maine, chose this handsome Hampton sloop as their shop’s inaugural construction project. The daysailer is based on a century-old original in the collections of Mystic Seaport in Connecticut.

John O’Donovan and Patrick Dole opened their business in 2008. After an earlier career as a New York City stagehand, John had attended the Northwest School of Wooden Boat Building, and then moved back East to work for some of the finest shops on the coast: Ballentine’s Boat Shop in Cataumet, Massachusetts; Beetle Cat in Wareham, Massachusetts; and French & Webb in Belfast, Maine. At French & Webb, he met Patrick Dole, who had sailed tall ships as a young man, and had then attended The Landing School of Kenebunkport, Maine, studying small-craft construction and systems engineering, before moving on to jobs at Rockport Marine and French & Webb. The two builders had impressive résumés by the time they struck out on their own, and they were looking for a boat that would showcase this experience, to be built on speculation. Their requirements boiled down to these three points:

1) The construction had to be within the shop’s budget; as much wood as possible would be sourced locally, and as much hardware as possible would be shopbuilt.

2) They sought a workboat with Maine ties. “A Herreshoff design might have been a wise financial plan,” John acknowledges, but they wanted something even more traditional—more rooted in working craft.

3) Finally, the boat had to be adaptable as a recreational daysailer.

Seeking perspective, the pair sought the counsel of several designers. “One of the designers we talked to said ‘this Hampton boat [CUSPIDOR] would be your best bet,’” said John.

CUSPIDOR had been launched in 1902 on Bailey Island, Maine. Despite being named for a New Hampshire town, the Hampton boats were well rooted in that state’s neighbor to the northeast. CUSPIDOR had been designed as a pure daysailer, and as such it was finer lined than its working cousins. Forward, the boat is narrow and deep, but it swells out to firm-bilged ’midship sections, and then narrows up again in the stern. The layout and rigging were meant for recreation, rather than for fishing. O’Donovan and Dole had found their boat.

Benjamin Mendlowitz

Benjamin MendlowitzThe Hampton sloop is built traditionally, which is to say that it’s carvel planked on steam-bent frames. O’Donovan & Dole brought a diverse resume of boatbuilding experience to this project, and are quite capable in a range of boatbuilding styles.

The new Hampton boat is an “interpretation” of CUSPIDOR. The hulls are identical, but the new boat’s layout has been modified for family sailing, and the rig is a sloop, rather than the more typical ketch. “We didn’t want a mast right there,” John said, gesturing to where I was sitting as I steered the boat. “We weren’t trying to build a replica of the boat; we were trying to build a boat for young families,” he continued as we set out from the docks at Stockton Springs on a drizzly early September morning. “We pulled a lot of details from other boats.” They were particularly inspired by the sheet leads of the Herreshoff 12½, and the seating arrangement of the Matinicus Island boat. The simple bronze hook-and-eye gooseneck also came from a Matinicus Island boat at Maine Maritime Museum in Bath, two hours south of the O’Donovan & Dole shop on Route One. “We went down there looking for details,” said John. “We tried to make as much of the hardware as we could.”

Some other shop-made items on this boat include the jib-sheet leads, which are fabricated from bronze bar, bent and fixed to the coaming; the bronze-rod center board pennant; a simple bronze mast gate that can be unscrewed from the partners for unstepping; black locust bow chocks; and a rack of belaying pins for the halyards. Subcontractor Tom Ward made the blocks, strops, and shroud-tensioning deadeyes.

I’d brought my 22-month-old son along for the trip, and it was immediately apparent to me that this was, indeed, a family boat. A boy that age requires constant vigil onboard. The Hampton’s cockpit is divided into forward and after sections by a thwart, and the after section has side benches for the helmsman. Forward of the thwart the space is wide open, and it’s a deep, safe place for young kids to play. They can watch for birds and buoys over the side of the boat, but it would take some effort to climb those sides and get to the water. While I wouldn’t underestimate my son’s ability to do this, there’s a security to this arrangement that’s absent from many shallower-bodied daysailers.

You’d think that so deep a cockpit would indicate a deep-draft boat, but that’s not the case here. The O’Donovan & Dole Hampton draws just 1′ 9″ with the centerboard raised. “That’s what I love about the centerboard,” said John. “We can go over to the beach on Sears Island and step ashore.”

This shoal draft, however, does not indicate easy trailerability, for there are other factors that affect this. This boat is carvel planked, which means that “she really just needs to go in and stay in,” said John. “I guess if you wanted to build a strip-planked version or a cold-molded version, she could live on a trailer.”

The skies brightened, the rain stopped, and the wind freshened during our September outing. The boat tracked well, with its long, straight keel. But it turns well, too; even in the light breeze, I felt no threat of being caught in stays. Of course, it doesn’t spin on a dime—you sail it through a tack—but this is a surpris-ingly maneuverable boat, given the depth and length of its keel.

Because we had wind, we didn’t bother with the oars. John told me, though, that he’s still working out the best, most comfortable way of rowing the boat. Initially, he’d tried sitting in the center of the thwart and rowing with a pair of oars, but that put him right on top of the centerboard trunk—an okay position for brief stints, but certainly not for a marathon. Sam Martinelli of Shaw & Tenney, during the cover shoot for this magazine (yes, that’s the Hampton boat nosed into the beach on this issue’s cover), suggested that John try sitting off to one side of the thwart, rowing with one oar, and adjusting the rudder to compensate for the single oar. That worked, and it seems the best way to propel the boat in a calm, when alone. When crew is available, one member should be assigned to the other oar.

The O’Donovan & Dole Hampton has a white oak keel and stem, white oak steam-bent frames, and Atlantic white cedar planking. The shape of the boat is such that John and Patrick could gang-cut three planks at a time, to the same pattern, and just tweak the ends a bit to get them all to fit well. The planking is fastened with bronze screws. As John suggested, the boat’s construction could be modified for wood-epoxy, though an element of her heritage would certainly be lost in doing so. The boat’s spars are Sitka spruce. While that choice might seem a violation of the economical, local-sourcing mandate, it isn’t. A local yard had some beautiful offcuts from a large project, and so the option was just too good to pass up. The boat’s materials list is adaptable to what’s available locally.

I was impressed with a detail back aft at the helm station: the cockpit sole’s carefully fitted and bent red-oak margin boards. While a more usual approach here might have been to build a wide elevated platform, the fitting of these boards to the inner hull, and the associated deep narrow sole in this area, provided a delightfully ergonomic footrest when sailing.

In fact, ergonomics are a hallmark of this boat’s layout. While it may seem a simple matter to rig such a boat, the careful location of sheet cleats, the tiller’s long length, and the mainsheet lead make the difference between an effortless outing and a frustrating one. I’ve sailed a Mackinaw boat of similar size and shape as this Hampton boat. That boat was ketch rigged, with foresail sheets out of reach of the helmsman, and tacking while alone was a project. The O’Donovan & Dole Hampton’s jibsheets are led practically to the helmsman’s hand, with cleats right there for easy belaying. John noted that he’s found these cleats to be a handy place to tie off the tiller when he needs to slide forward to tend something. One must simply lean forward from the helm to trim the mainsail. An added benefit of leading lines to a single station in a family boat is the comfort of knowing that sheet tails aren’t living with kids; I’m ever aware, when sailing with my son and his friends, of the perils of a line wrapped around an ankle—or worse.

We often hear the phrase “family boat,” but without a lot of description of what, exactly, that means. My short trip in this Hampton boat last summer really helped me to refine my understanding of the label, and this simple, beautiful, and functional boat fits the bill. ![]()

Plans for CUSPIDOR are available from Mystic Seaport. Contact Ships Plans.

Finished boats no longer available from O’Donovan & Dole.

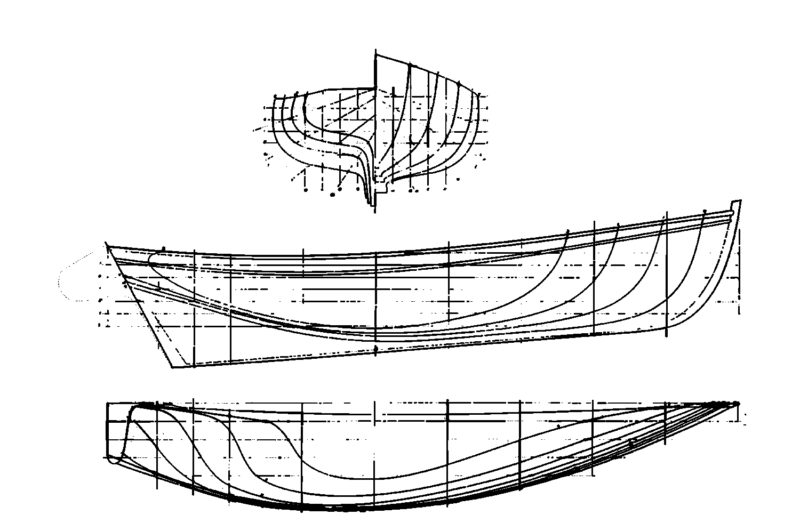

The O’Donovan & Dole Hampton boat is built faithfully to CUSPIDOR’s lines, which are shown here. The new boat’s ergonomic layout is the product of much research and thought by O’Donovan & Dole. Particulars: LOA 17′ 4″, Beam 6′, Draft (cb up) 1′ 9″, Draft (cb down) 3′ 2″, Displacement 2550 lbs, Sail area 170 sq ft

Looks a very pretty little ship. It would seem though that something’s a little wrong with the particulars at the end of the article.

Would a higher bow be advisable, since my sailing would be on Lake Michigan. Being a large body of water, storms arise quickly. Would an electric aux motor be advised, using solar for power source ?

Well, Gordy, this being a 100-year-old sailboat design: any kind of motor, solar or fossil fuel, would wreck the ethic. On Lake Michigan I always recommend carrying lifeboats, and those could be powered.