Audrey and I have a stable of 16 small boats, and we often need to move them off and on trailers for maintenance and repairs. Audrey has a background in theater-set construction where the crews avoided lifting anything when a lever, dolly, line, or block-and-tackle would do, and after watching me struggle while moving boats, she designed a simple sling lift to reduce wear on me as well as the boats. Each sling in the authors' pergola has a cleat (left) to secure the working end and a single block (top) secured to an overhead beam with a pad eye. The stationary end of the line is secured to another pad eye. Here the author’s 1965 Alcort Catfish is being lifted from its trailer for some hull repairs. Photographs by the authors

Photographs by the authors

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.

Comments (8)

Leave a Reply

Stay On Course

Does anyone have plans for a purpose-built frame that could be built to support the cleats, pulleys, and boat? I have a 125-140# monohull to flip. Please reply to [email protected].

Thank you.

Nice article, what many would consider a difficult task, made easy and well explained.

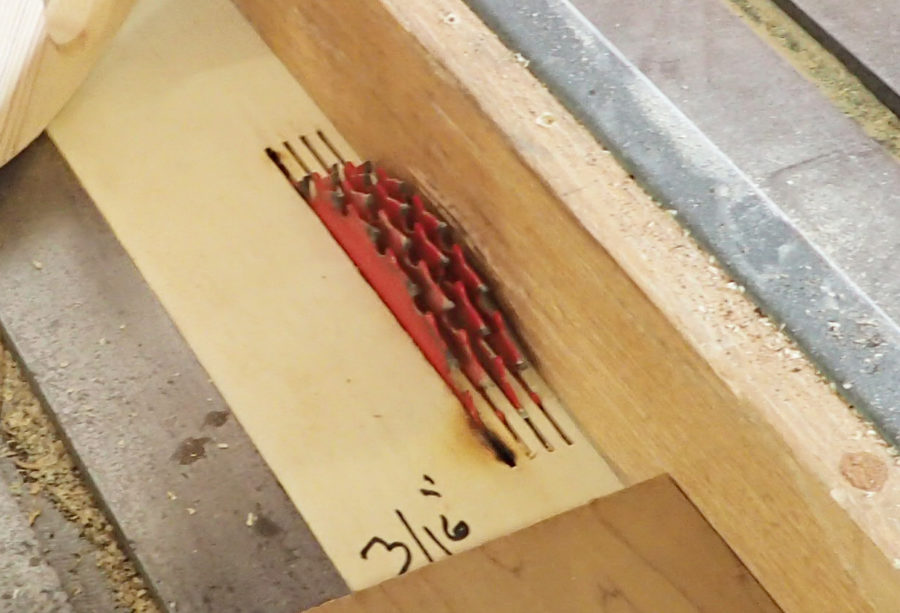

I’ve done a version of this which also acts as part of a small-boat storage system. A webbing sling goes under the hull from spreaders to which the hoisting line is attached. In the loft of the garage there are a bunch of blocks as the fore and and aft slings are married to a line that goes to the critical component of my system, a trailer winch mounted to one of the studs on the garage wall. I set up the webbing slings around the boat on a trailer, then start cranking on the winch and the boat goes up. I’ve also used the system to hoist a skiff for easy bottom painting.

Here’s a photo

I too work in theatre, I have been considering a pair of 1/4-ton chain hoists for this same purpose. As they run on 120v unlike their bigger 1/2- and 1-ton cohorts, I could easily run them in my garage. This system they came up with has the advantages of being much cheaper and a lot more simple to implement.

I like that spreader idea. It is important to set our attachment points wide enough to not pull a hull inward, better to be too wide than not wide enough. Your spreaders take care of that.

One of the things not obvious in the pic of my ducker is that I have a block on each spreader so that gives me a 2×1 purchase before it gets to the winch.

As a one man band building a 4-meter dinghy, I have been looking for a method to turn the boat over safely and this system could be just the ticket

What a useful solution and discussion that elaborates on it.