A blast from the past, RETRO-ROCKET skims across the glassy surface of Minnesota’s Lake Minnetonka. At 10′ 2″ LOA, a 5′ beam, and 12″ draft (standing still), this pocket-sized hydroplane was built by Rob Sotirin for his son, John, to run in the waters off the family’s Shady Island home.

Named for the boat’s old-time style and its speed, RETRO-ROCKET is a throwback to the small outboard-powered hydroplanes that were popular during the 1940s, ’50s, and ’60s. After World War II, plans for do-it-yourself builders were available through boating and woodworking magazines, sparking an interest among returning veterans, and others, who were looking for on-the-water excitement at a reasonable price. Best of all, these boats were of a size that could easily be constructed in a home workshop.

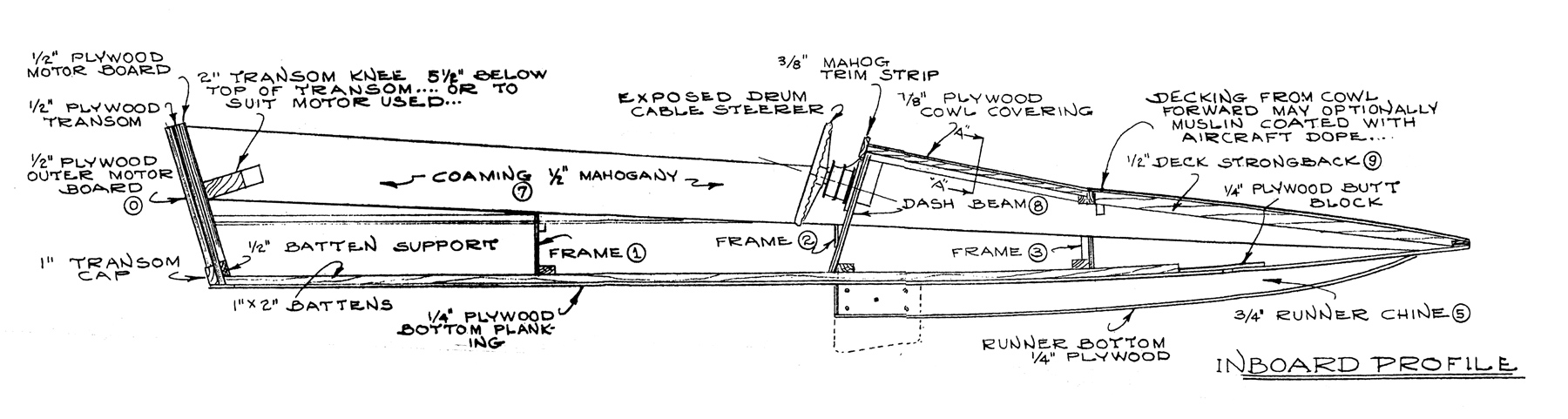

RETRO-ROCKET was built from Glen-L Marine Design’s plans for Super Spartan, a three-point hydroplane. Constructed in marine plywood, RETRO-ROCKET weighs less than 100 lbs and darts across the water, mostly on a cushion of air. A three-point hydroplane has two forward sponsons, plus the aft end of its hull, which is flat. When on plane, only the sponsons and the aft bottom surface touch the water.

At an overall length of 10’2” and weighing just 100 lbs, Glen-L Marine Design’s Super Spartan looks like she’s ready to race but is mostly intended to provide summertime fun on calm waters.

Rob built the Super Spartan to keep pace with the interests of his children. “My son John is now 13, and I figured he would be ready for a little excitement. We live on an island, so the kids spend a lot of time on the water.” At the outset of the project, Rob took time to carefully read and understand the plans. “I found it useful to have them posted right next to the ‘operating table’ so that I could turn around to refer to them every step of the way,” he said. “This is such a small, light boat that there isn’t much in the way of materials or cost. Glen-L does a nice job of providing step-by-step pictures of the construction process.”

Facing another Minnesota winter, Rob began work on the hydroplane in his basement workshop. Thinking ahead, he constructed a full-sized mock-up out of scrap wood to assure that he would be able to get the boat up the stairs and out the door when his project was complete. By the following summer, the boat was ready to launch.

RETRO-ROCKET’s bottom is made of 1⁄ 4″ marine fir plywood and the deck is 1⁄8″ mahogany plywood. He used two layers of 3⁄4″ solid mahogany for the transom. The stringers and cockpit cowling are also made of mahogany. Rob remarked, “The idea is that with very little hull weight, a small motor will accelerate the boat quickly and bring it up out of the water [on plane].”

Rob purchased Glen-L’s fastening kit, which is specific to the Super Spartan and includes silicon-bronze screws and ring nails. He assembled the boat’s lower hull stringers and transom with 3M-5200, assuring that seams were watertight yet allowing the hull to remain somewhat flexible. He bonded the less vital deck pieces with a polyurethane construction-grade adhesive, which is less expensive.

Photo by Rob Sotirin

Photo by Rob SotirinRETRO-ROCKET’s stained-and-varnished 1⁄8″ mahogany plywood deck is pleasing to the eye. Strategically placed racing stickers hide seams where plywood sheets were butted to one another.

Well before Rob installed the deck, he sealed, primed, and painted the hull’s forward interior. Water that gets inside the boat can collect in the sponsons, so it’s a good idea to make sure they are protected to discourage rot. He stained and finished the aft interior (which is visible) with four coats of varnish, along with most of the outer hull. The cowling pieces were left natural to provide a two-tone effect and allow sufficient contrast with the lettering. Rob strategically placed a large racing number (even though his son doesn’t race) to hide the butted seam between two pieces of deck plywood. “I took a lot of extra care so that the whole boat could be varnished,” Rob added. “This made for a lot of critical attention to fit and finish. However, if you planned to paint the boat, you could be a lot less fastidious.”

As RETRO-ROCKET neared completion, Rob was concerned about the comfort of the driver, who must kneel on the cockpit sole when the boat is underway. “It’s important to put something down to absorb shock and stay dry,” he said. “At a local surplus store I found just the thing—the long black foam wrist rests used with computer keyboards. I bought 20 of them, and that’s what you see lined up on the floor [sole] of the boat.”

As a practical matter, Rob recommends that strong stainless or galvanized eyehooks be built into the boat’s hull before the deck is attached. This allows owners to store the boat by hanging it in the garage over a car. “With the motor off, a couple of people can easily lift [the boat] off the trailer and pulley it up to the rafters,” he explained.

Stock boat trailers require some modifications to accommodate the Super Spartan. The hull is basically flat, so Rob built some bolt-on attachments to his trailer that provide the bow the support it needs, while keeping the back end from sliding sideways. He can use the same trailer for several small boats this way.

Photo by Rob Sotirin

Photo by Rob SotirinThe simple design of the compact-sized Super Spartan let Rob Sotirin complete this racy little hydroplane over the course of a Minnesota winter in his basement workshop.

Flat water is critical to the safe operation of RETRO-ROCKET, which is only allowed to run on relatively smooth days. Underway the “shovel nose” bow is only inches above the lake’s surface, and a wave could cause the boat to “submarine,” or dive under the water. The other extreme is that the boat can go airborne. To keep this from happening, the driver must lean forward, especially when accelerating. “It’s easy once you get the feel for it, but can be dangerous to the uninitiated. No one is allowed to drive without a proper understanding of how to handle her.”

Glen-L calls for a short-shaft outboard motor up to 35 hp to power the Super Spartan. Rob chose a 1960s-vintage Merc 200 (20 hp), which he found through word of mouth. “I spent some time getting it ship-shape with new paint and a few new parts, but it’s reliable and fits the boat very well,” he said. “I found other parts like the steering components, gas tank, and remote controls online. I find that 20 hp is more than enough to scare you. It does an easy 40 miles per hour with my son at the controls, and that’s plenty fast for both of us.”

Though RETRO-ROCKET looks like she’s ready to race, she’s really intended for family fun—providing summer-time thrills on calm waters. She certainly achieves that goal. ![]()

Super Spartan by Glen-L Marine Design is an ideal beginning project for adults or youths (with a little help from dad or mom). Construction of the three-point hydroplane, using sheet plywood planking, is straight-forward, requiring no building form.

This Boat Profile was published in Small Boats 2009 and appears here as archival material. Boat plans for the Super Spartan are available on Glen-L’s website.

Great pick for the kids—and you. My first involvement in boat building was helping my dad build a hydroplane in 1960. It was from Popular Mechanics and was made from two sheets of 4’x8’ outdoor plywood with glue and screws. It was designed for 5 hp max, but my dad got a great buy on a 20 hp! We had to have a person crawl out front to get it on plane, then go like crazy, for sure. I have had seven boats since then, four of them wooden boats. Hopefully, your project will instill a lifetime happy experience in your children’s lives. Nice job!

Back in the mid ’70s, fiberglass products were fairly new and in my ninth-grade wood-shop class some of the kids were interested in boats. Two kids out of each class period of the day worked on making a plug or replica of a finished hydroplane boat that was about 9′ long. The plug was made up of wood and other materials and polished to a fine finish. A mold was taken off of both the top and bottom with reinforcements to keep things straight. Each half of the finished boat was made in its respective mold and polyurethane foam was added and the whole thing clamped together while the foam expanded inside for flotation. When cured, the clamps were removed and out popped a finished hull ready for hardware. Looked great, worked great, and a good project for kids to learn how to work as a team even when not in the same class period. Each that worked on it got a finished boat by working together after school. Time was not a factor once the molds were made. One of the kids went on to be a professional racer at the seven-liter class and another lad, while not on that particular project, but on a similar one was one of the crew members on the Miss Maddison at the unlimited level.

We sell our young kids too short these days. They are capable of doing far more than we give them credit for. All we need to do is have them develop an interest with a good attitude and they do the rest on their own. Unfortunately for our school district, none of those shop programs exist any longer. In 1975 I had moved on to the high-school program in the same district. We just stepped up the game a bit there. I have been blessed with finding a lifetime job working with great people over the years that I am still doing at the age of 82. I am just one of those hands-on kids that loved the shop classes in high school. Even at that, I was far from being one of the best students in class. We need to remember that nothing gets done without a need. Sorry to see so many of the hands-on classes go to the wayside. We just might have a need for them to come back some day. I wish I knew how to get some of the photos to you of some of the work that those kids have done over the years. Thanks for reading this far.

Maynard Oliver

Hi,

I also had one of these in the ’60s. We had a cabin on Glendo reservoir (Glendo, Wyoming) and my dad built two boats in our garage. A 20′ cabin cruiser, with one of the first Berkley Jet drives. That’s another story. Then he built me a small hydroplane from some plans in Popular Mechanics.

Man, was it fun! It had a 15 HP Mercury outboard and would really haul a**. One of my dad’s friends convinced him to modify the engine to burn hotter gas. :(. It wouldn’t start very easy after that, but when it did, man. It was fast! I wish I had a photo or two, but alas, they disappeared during some moves my parents made later.

I remember one of my jobs was applying soap to the thousands (it seemed like) of screws he drove into that big boat.

Congrats on your project, may you have many years of enjoyment !