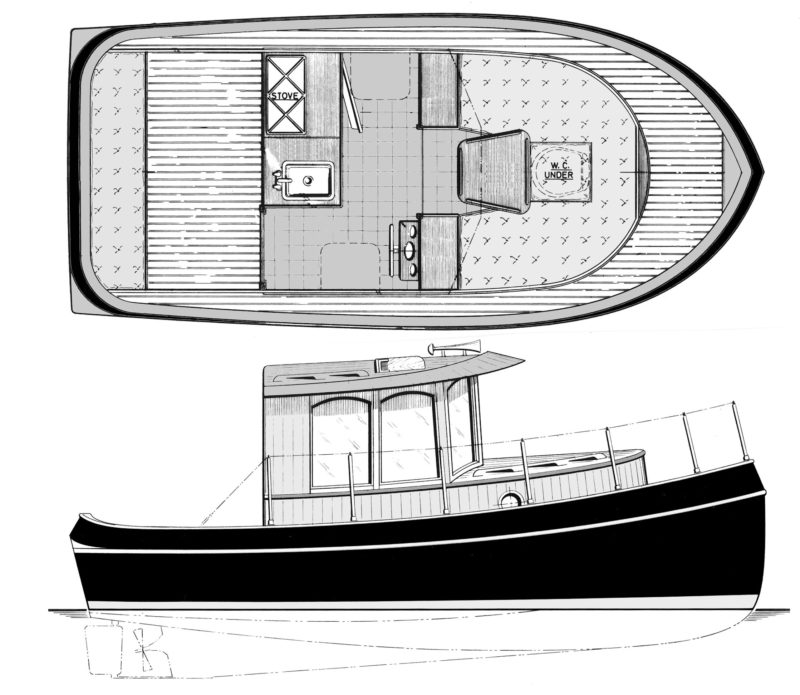

Glen-L’s Bo-Jest is an 18′ pocket power cruiser designed in 1986 by Ken Hankinson. I loved its tugboat style and its just-right size for our cruising needs—big enough to stay in for a few days and small enough to avoid high moorage costs.

The three pages of plans I ordered from Glen-L were clear, but required extra study for me as this was my first plans-built boat. (I had previously built an Adirondack guide boat from a partial kit.) The plans were well drawn, and the full-sized patterns for the frames were accurate and required no fairing during assembly. The 16 pages of accompanying printed directions were thorough and easy to follow. The plans provide details for the installation of an inboard motor—specified to be no more than 10 hp with a weight of about 240 lbs—and the option to configure the stern to take a 5- to 10-hp outboard. I built the outboard version so I could use the space in the pilothouse that would be otherwise occupied by the inboard-motor housing.

Earl Boissonou

Earl BoissonouThe plywood takes to the aft half of the hull without fuss. Forward, the 3/8″ sides need some hot water to take the curve, and the twist in the bottom has to be done with two layers of 1/4″ plywood to achieve the 1/2″ thickness required.

The Bo-Jest uses traditional plywood-on-frame assembly, and the plans call for mahogany, oak, and Douglas-fir for the timbers; I chose Douglas-fir for its strength, easy availability in Oregon, and long-established use as a boatbuilding material in the Northwest. Some steam-bending is required for the stringers, plywood at the bow, trunk cabin, and main-cabin brow.

I was 77 years of age at the beginning of the build, so I eased the physical burdens by hiring a 14-year-old boy from the neighborhood to apprentice with me. A friend helped off and on throughout the build, and many others assisted in the heavy work of flipping and moving when needed.

The stem, five frames, and the transom are connected by a plank keel, the chines, and inwales. Three battens on either side of the centerline are let into the bottoms of the transom and the frames and their forward ends stop shy of the stem. The aft two-thirds of the hull goes from a slight V forward to a nearly flat stern. There’s similarly very little shape in the sides aft, so the 3/8″ plywood goes on easily. I eased the bending of the 3/8″ plywood sides at the bow with rags soaked with boiling water, muscle power, clamps, and a come-along. The 1/2″ bottom is made up of two laminates of 1/4″ plywood; bending the thinner plywood to shape is much easier.

After the hull was finished and while it was still upside down on the jig, I made two gantry cranes equipped with ratcheted truck tie-down straps to turn the hull. (I’d use the gantry cranes later, to lift the completed boat onto the trailer.) I also devised and built a cradle to rest the hull on after it was right-side up and finished construction with the hull upright. I used the cradle as a pattern to build adjustable contour bunks on the trailer.

John Kohnen

John KohnenThe pilothouse and the trunk cabin offer plenty of shelter space. The settee to port in the pilothouse is a custom replacement for the galley detailed in the plans.

As I scanned the plans for Bo-Jest, I realized the original floor plan for the pilothouse and trunk cabin would be rather crowded for our use. The Bo-Jest was designed for self-contained cruising with sink, stove, refrigerator, potable water tank, and closets. I too wanted this kind of cruising ability, but I was willing to sacrifice the built-in galley for a more open space. I raised the pilothouse roof 3″, which adds a spacious feeling. Having lived now with the modifications I made for three years, I’m happy with them.

Gas cans, battery, and stern anchor are all located in the aft cockpit. The gas cans are partially hidden by hinged seats, the battery is located in the starboard stern locker, and life jackets for six are located in the port stern locker. Three to four people can sit in the open, self-draining cockpit.

An ice chest, a small butane stove, a few pots and utensils, and a dishpan are all we need for cooking. We keep a bucket-style portable toilet stored under the pilothouse settee and a small carbon-monoxide-sensing propane heater stows in a locker under the trunk-cabin V-berth. All other gear is stored in lockers in the same area.

John Kohnen

John KohnenGlen-L notes that the Bo-Jest’s length of 17’10” can be stretched to 19’7″or shortened to 17’8″ by changing the frame spacing by up to 10 percent.

Our pilothouse has a settee portside with storage drawers instead of the compact galley in the plans, the helm to starboard, and a center entry door. (An inboard-powered Bo-Jest will have the door to starboard of the engine box.) Down below there is a very roomy 7′6″ V-berth in the trunk cabin. I compensated for the weight of the plans’ potable water tank, which I chose not to install, by using round barbell weights secured in the same forward location under the V-berth. This helps maintain correct trim.

The Bo-Jest was designed to be powered by as little as a 4-hp outboard, but I chose a 9.9-hp, the maximum recommended, and I’m happy with that choice. I gladly would have installed electric propulsion if it weren’t so expensive and offered greater range from a lithium-ion battery pack.

Our Bo-Jest has a top speed of 7 knots, cruises nicely between 4 and 6 knots, likes 5-1/2, and will gunk along at a snail’s pace. I wanted more positive low-speed control at the helm and achieved it by mounting an Uncle Norm’s Marine Products double-finned rudder to the cavitation plate of the outboard. This provides great low-speed steering control, which aids in docking, even while coasting with the engine in neutral. The boat has some windage issues because of its tall profile, and the steering accessory works well to minimize them. Another nicety of this hull design is its turning ability; flip the wheel riotously fast, and the boat will come about in nearly its own length! It is stingy on gas: less than ½ gallon per hour at 5-1/2 knots, and at 7 knots consumes about 6/10 gallon of precious non-ethanol gas.

John Kohnen

John KohnenPowered with just a 9.9 hp outboard, painted to match the boat’s color scheme, the Bo-Jest can hit 7 knots.

I haul the boat with a 3.5-liter V6 Ford Flex. The loaded trailer pulls easily with no sway, and with the electric brakes I installed on the trailer, there’s no trouble slowing or stopping.

I would not rate this a project for a beginning boatbuilder unless the builder has previous more intricate wood project experience. However, motivation can be powerful and provide success to a dedicated novice builder like me. I spent two years and ten months working three to four hours per day, five days a week, to complete this project. Phone calls to Glen-L cleared up any questions I had along the way.

The Bo-Jest is very comfortable and roomy for a boat with a length of only 17′10″. The trunk cabin is cozy—many who come aboard enjoy napping below; two people can be very comfortable overnight. The pilothouse is quite comfortable with the settee on the port side, and a well-equipped pilot station makes navigating the boat easy.

John Kohnen

John KohnenThe pilot house is designed to have standing headroom from 6’1″ to 6’4″; the cabin has seating height from 4’1″ to 4’4″.

I am now 81 and have piloted our Bo-Jest many miles. I have navigated the Yaquina River near Newport, Oregon, and have made other excursions in Washington’s Puget Sound, including participating in the first Salish 100, a 100-mile pocket-yacht cruise. More voyages lie ahead, and I look forward to them.

I would happily recommend this design to anyone who appreciates its jaunty, salty looks, and quite-good handling. Unlike many small craft, this boat provides extended use at both ends of the boating season.![]()

Earl Boissonou, 81, lives in Corvallis, Oregon, and is a retired elementary-school teacher. He is a passionate artist who draws, paints, and sculpts. He began sailing in 1968 and built his first boat, an Adirondack guideboat, in 2009 to keep busy while recovering from a major operation. He christened it CHERRILL B in honor of his wife. While building his Bo-Jest he had the help of two neighbors: young Caleb Washburn and Dr. Bruce Thomson. The boat was christened DR. PETRA, a nod to Dr. Pepper soda and tribute to his doctor friend, Bruce, and Petra, a family dog that had passed away.

Bo-Jest Particulars

[table]

Overall length/17′10″

Waterline length/17′

Beam/7′11″

Hull type/Semi-displacement

Displacement/2,660 lbs with inboard; 2,350 lbs, as-built, with outboard

Horsepower/9.9 maximum

Cruising speed/4 to 5.5 knots

[/table]

Plans with patterns for the Bo-Jest are available from Glen-L for $188.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us!

I had the great pleasure of meeting Earl and Dr. Petra during the inaugural Salish 100. Although I’m still sailing small boats, I really admire this design and easily see myself wanting a Bo-Jest in the future. Hope to cruise with you again, Earl!

Eric

Super cool! I am a mere 73.8 years old and building a Joel White designed Marsh Cat cat boat. Earl infuses me with enthusiasm!

I had a boat much like Earl’s designed by Scott Sprague, tug-like but 26′ long with more traditional building methods, i.e. no plywood. I’d love to build an inspired tug boat again called Basher. Seems to me like a suitable name for a tug.

Great work Earl! Lovely!

I have found that plywood bends readily with heat only–no moisture necessary. I haven’t tried it yet in bending a plank, but have done it with quite a few smaller projects. For a large panel, such as the forward end of a bottom plank (which is often the most challenging part of planking with plywood), I would experiment with one of the old style infra-red heaters with a reflector to concentrate the heat. I’d apply the heat until it can be felt on the other side of the panel. There are other sources of heat that might work, as well.

I like this idea much better than the old practice of draping towels over the panel and soaking them with boiling water. For one thing, you would have more control over the application of the heat. Also, you would avoid grain raising, which is especially problematic with fir plywood, and you wouldn’t have issues with glue on damp wood.

Wonderful boat and story. Thank you for your service, Sir!

Earl, this is a great article, and you captured the excitement and joy of building and operating such a boat very accurately! The little tug Robert Hale mentions above was mine after he let it go, and I wish I’d had the foresight to solve the galley/settee challenge in the way you did – well done! A suggestion to the editors: The whistles Earl built for DR. PETRA always draw a lot of attention, as does his art work. Perhaps you could find space for a closer look in future editions?

The cylinders that supply air to Earl’s whistles/horns caught my eye when I was studying the photo of DR. PETRA’s pilothouse.

I made a few horns—see “A Little Big Horn”— but none as elegant as Earl’s.

I found some of Earl’s artwork on the web. He and his wife Cherrill are both talented artists.

We’d be happy to see if Earl is willing to share details.

Christopher Cunningham, editor, Small Boats Magazine

I would love to see some photos or hear more about your home-built gantry cranes that you used in the build.

Agreed, bring on the gantry cranes!

Robert

Thanks, Earl, for the great article. Your work is inspiring! I am in the midst of building a 21’ trawler. Like you, I chose to eliminate inboard power and have debated electric. Not enough room between keel and transom for a well, so it will be a transom outboard, custom-painted like yours. While considering a Glen-L build, I found a “new” 20-year-old lapstrake displacement hull (moulded by Independent Shipwrights on Vancouver Island) and have built my own interpretation in marine ply and epoxy. The Pilothouse is almost finished. Incidentally, I built a rolling dolly which allows me move the boat freely, and get through the garage door for sanding outside on sunny days. For transferring to the trailer, I use a 4×4 gantry for lifting the bow, and jack stands at the stern. I’ll finish the interior this winter, and perhaps make it to Salish 100 in 2020.

I’m so happy to see Earl’s article about building our Bo-Jest! He’s such a wonderful man and has been a pleasure to talk with over the years and even meet in person at our office. He has certainly done a beautiful job building his boat and putting his own special touches on her. Congratulations!

Gayle Brantuck

Glen-L Marine Designs

Would love to see more on the cranes and ideas for the head. What a great project. Didn’t see anything about steaming the plywood in the instructions though.

Beautiful execution of a terrific design.

It would be wonderful if Earl could write a Technique article about his gantry cranes.

Earl and I will be working on an article about his gantry cranes for a future issue.

Christopher Cunningham, editor, Small Boats

Yes please!!!

Would love to see some additional cabin / interior pictures as well. Great job.

Does anyone know of a boat yard that might build one of these?

I think I’m in love with her. Just beautiful and just what I need to downsize from a Eastern Sisu 22.

If anyone knows, comment here.

Chris, you might talk to the Northwest School of Wooden Boatbuilding in Port Hadlock WA for starters; failing that, I would imagine they might be able to point you to a number of grads who could build it for you.

Wow, Earl. I am so impressed with your work. I have ordered a set of plans. I live in Bremerton and would love to see your boat in person. But, that is a way off with the virus situation. I have LOTS of questions.

Really impressed with your work. My Bo-Jest is nothing fancy compared to yours. Of course, it’s in the fine-tuning stage (wiring and seating).

Curious on how you sleep in cabin-head for’ward or aft? I find that I can slither out to sitting position easier with head for’ward.

Interesting boat and excellent article. Would love love to see comments, suggestions, experience with electric propulsion and solar panels.

I am in the process of buying a Bo Jest that needs some fixing up. Can anyone tell me how seaworthy this design is? Is it more of a calm water boat or can it handle a little bit of waves and such? Thanks in advance.

-Russ

I have a Yamaha 9.9 high-thrust on my Bo-Jest boat. I found out that I need spray rails on bow out in the rough stuff and could use a little more power when out in a following wind as the waves tend to push the hull port and starboard (trying to broach). Makes for interesting steering. I usually only run at 1/2 to 3/4 throttle as motor noise is louder at full speed and I don’t go that much faster anyway.

I too have admired this boat design for many years. I have had a set of plans and break them out every so often. I recently finished a Stevenson Projects sailboat which turned out nice. Being that I am retired I think I will start my Bo-Jest soon. My plan is to complete a Great Lakes loop, up the Erie Canal, North to Canada and back down south and back to New York. This trip would take 3 months and will follow the Great loop play book by Capt. John. This should be a fun trip at 6 miles an hour.