Rosemary Wyman

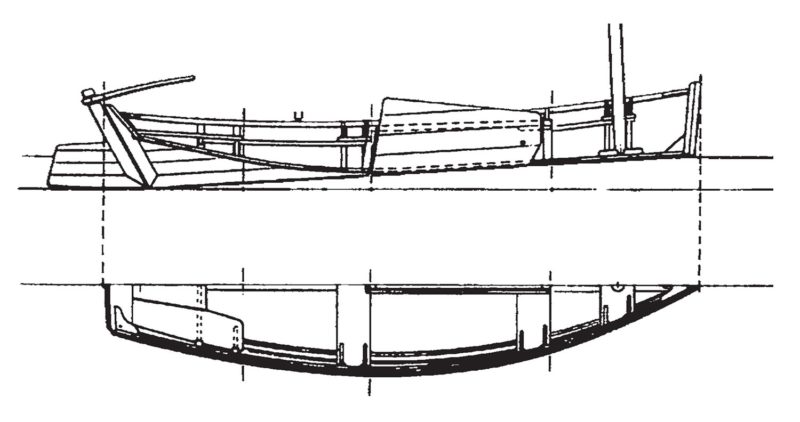

Rosemary WymanAndrew Kitchen of Irondequoit, New York, had always wanted to build a sharpie, and he settled on Reuel Parker’s adaption of a historic boat recorded by Howard I. Chapelle, originating from Cape Cod. The sail reefs by being drawn to the mast.

When people rhapsodize about shapely curves in boats, they usually are taking inspiration from round-bottomed hulls, often with wineglass transoms. Doing so, however, leaves off entire sets of criteria—ease of construction, cost, practicality in use, suitability for local waters, and form stability among them—that will ultimately be in the mix, like it or not, when a boat is judged to be a success or a failure. When a full set of criteria is brought into play, it is apparent why flat-bottomed and hard-chined boats have survived the ages as well as their round-bottomed cousins. The surprise is that they can be every bit as eye-catching.

Andrew Kitchen, an upstate New York resident who has an eye for quite a variety of boats, had his head turned last year by a sharpie, a historic American workboat type used far and wide. The particular model he admired was adapted by Reuel Parker as a 14-footer intended for pleasure use and published in his The Sharpie Book. Parker’s version was based on an 18′ workboat used on Cape Cod for oystering and documented by Howard I. Chapelle in his classic American Small Sailing Craft. Kitchen was casting about for what would be the fifth boat in his fleet, which now ranges from a MacGregor canoe to an Iain Oughtred–designed Ness yawl. He even dreams of building a heavy Yorkshire coble of the type he grew up among in his native England. For the winter of 2012–13, he settled on the sharpie, which he could build mostly using materials he had on hand, even sewing the sails himself from a Sailrite kit. His goal was to have the boat ready to sail solo in the 2013 Small Reach Regatta (SRR) in Maine, in which he has participated regularly for many years.

Rosemary Wyman

Rosemary WymanThe sharpie’s flat bottom has ample rocker aft, bringing the nicely shaped transom above the waterline.

“It was a nice little project,” he said. “It was something I could have in a short period of time, and I decided in the fall that I had to build it by the summer—I couldn’t spend my usual one or two years on the boat.” He usually sails on Irondequoit Bay off Lake Ontario, and originally he had in mind bringing his MacGregor to Maine for the annual rendezvous. To prepare, he tried a new rigging setup meant to improve versatility, with the varied conditions of solo sailing on the coast in mind. It didn’t go well. “I thought, I’ll do this, and I’ll see if I like sailing it this way. So I took it out on the bay, and proceeded to have a great time until I got hit by a gust of wind and capsized. There I am in a tangle of masts and rigging, because there’s so much rigging on a boat like that. So the MacGregor, I decided, is not the boat for me,” at least not for the SRR. “You can’t hike out, and you’re a sitting duck if the wind hits you.”

Given that experience, the simplicity of the sharpie’s rig, not to mention its hull form, kept Kitchen coming back to Parker’s book. The boat would be easy to handle while sailing alone, even in comparison to his Ness yawl, which he ordinarily sails with crew. Ideas started to percolate.

Rosemary Wyman

Rosemary WymanTurning blocks on the mast partner lead the snotter line (at right in the photo) and the reefing line (at left in the photo) aft to be in easy reach.

Rosemary Wyman

Rosemary WymanThe plywood centerboard, shown here fully retracted and pinned, lowers by means of a hinged handle visible along the top edge of the board.

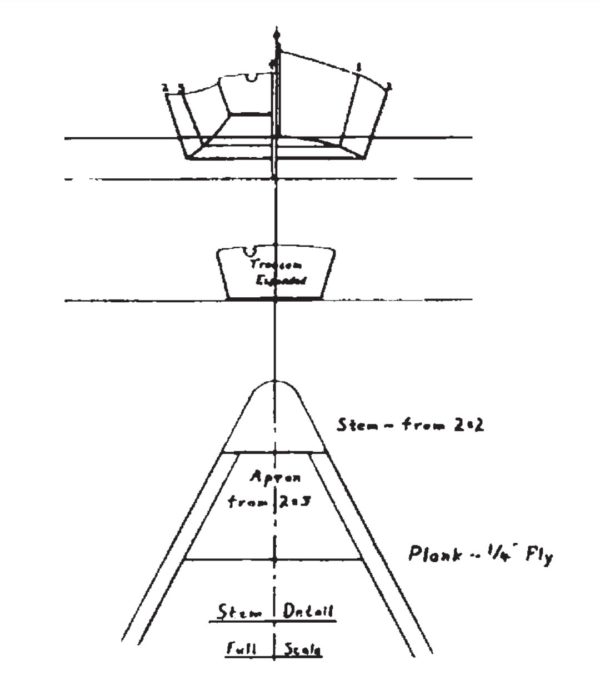

Kitchen is an inveterate tinkerer. His boats show personalized solutions to problems, and a distinctive and personal style of woodworking. “I was trying to use as many scraps of lumber as I had to keep the price down,” he says, including some sheets of okoume plywood, 1⁄4″, which he used for the sides and 3⁄8″ for the bottom, sheathed on the exterior only in 6-oz fiberglass cloth set in epoxy. The interior is coated first with Deks Olje No. 1 and then painted, a method Kitchen favors for all his painted or varnished surfaces. For some assemblies, he joked, “the inside is kind of the way they used to build cathedrals in Britain—the outside looks beautiful, but the inside is just rubble!”

His tinkering with this boat started with the shape itself. “I wanted a sharpie,” he said, so he stretched the length from 14′ to 15′ overall, adding about 1″ of freeboard one-third of the way forward from the transom and 11⁄2″ at both at the transom and the stem for a bit more spring in the sheer. He did this by simply expanding the spacing of the station molds, which meant there was no corresponding increase in beam. “I may be damned for it, but as I wasn’t increasing the sail area,” which is 75 sq ft in a single triangular sail, “I felt all I was adding was stability and, for an old person, it’s good to have a boat that you can handle.”

For the SRR, he wanted a boat to fit the rules and the spirit of the event, which calls for seaworthy sailing boats that have oars as their auxiliary propulsion. The boat’s beam of 4′ 3″, however, posed a rowing puzzle: the gunwales were rather close together for effective rowing, and low enough to put the oar handles in conflict with knees. Kitchen’s solution was to create wooden outriggers, simple wooden constructions in a loose L shape that slip alongside the side panels, to be trapped by both the inwales and seat risers. The result is that the oarlocks are higher than the gunwales by a couple of inches and outboard by about 10″ per side—without the need for complicated and permanent hardware that would be in the way while sailing or trailering. He uses 9′ oars, the same oars he uses for his Ness yawl. Fitting the outriggers is simple and handy, and in my time at the oars, overcoming a strong current in light air, I found the rowing enjoyable and the boat easy to move.

Rosemary Wyman

Rosemary WymanThe boat’s shop-made wooden outriggers are L-shaped. One leg slips down along the inside face of the hull planking, to be snugly held by the gunwale and the seat riser, permitting the use of 9’-long oars and greatly improving rowing efficiency for a hull that is only 4’3” wide.

Kitchen also took a hard look at the rigging. The triangular sail is low-profile and uses a sprit-boom, a marvelously effective device for making the sail flatter or fuller to adjust to any wind condition. The line that captures the heel of the sprit—called the “snotter” line—is hauled to increase sail tension or eased to reduce it. The plans leave a lot of room for interpretation on how the rig actually works, so knowing that he was planning to sail solo, Kitchen wanted the snotter line led aft, where he could reach it from the cockpit without having to leave the tiller. The line belays to a cleat to port, making the reach a simple one.

He also wanted to be able to reef the sail from the cockpit, which presented a more complicated problem. To reduce the area of this kind of triangular sail, traditionally, reef nettles were built into the sail in a vertical line, parallel to the mast, to which they would be made off. It was always a clever and simple way to reduce sail area, but in practical terms it meant getting the mast down to reef. Andrew had the idea of linking the reefing lines through brass loops, leading them in a series to be spliced into a single reefing line that could be led aft to a cleat to starboard. The system works well in reefing—the sail can be shortened quickly this way. In casting off the reef, however, he found that the lines tended to bind, preventing the reef from shaking out fully. “I wish I could say that it’s entirely successful,” Kitchen said. “I look at a problem and basically try to solve it myself. This is basically a bunch of brail lines, and I wanted them all going to one line that I could lead back to the cockpit.” Kitchen’s “full disclosure” admission during our sail was that he launched the boat only a week before the SRR, so he had little time to work out any bugs. Clearly, however, his mind was already turning over modifications and improvements, starting with how the reefing lines can be made to run freely and how to keep halyard tension on the reefed sail.

Designer Reuel Parker has long been an admirer of sharpies, and for The Sharpie Book (International Marine, 1994), he took a fresh look at numerous designs, one of which was an oyster skiff used for the shoal waters around Cape Cod. He adapted the boat for plywood construction—a simple task for a flat-bottomed boat—and reduced its length to 14’. Andrew Kitchen, who built the boat shown in this article, adapted the design by adding a foot of length and raising the sheer a bit.

Kitchen took admonishments from both Chapelle and Parker seriously for this boat. Both warned about the danger of capsize and the need for careful work at the tiller. Kitchen never cleats his sheet, instead taking it directly from a turning block to his hand. He also fitted four sizable flotation bags, especially since the top of the centerboard trunk is open, making bailing much harder if the boat is awash.

In sailing, the boat can tend to pound, especially in motorboat wakes. It can also be difficult to tack in a chop. “She handles well in smooth water,” he says. The boat also goes to weather well, often pointing higher on the wind than other types. So far, he has concluded that the boat doesn’t sail terribly well in light air—in fact, “I find her a little bit of a dog in light air. Most of the other little boats were overtaking me. The only advantage I had was I found that I kept up with them because when tacking I could get closer to the wind than they did. She likes a fresh breeze, but not overpowering—then she takes off.”

We had weather like that often at the 2013 SRR in Muscongus Bay, and I observed Kitchen’s boat moving well, with her transom tucked up prettily and the heel of the stem riding just above the surface, which Chapelle noted was the trim favored by working sharpie sailors. And there was Kitchen, in a big floppy hat, the tiller in one hand, the sheet in the other, and the biggest grin imaginable. ![]()

Plans available from Parker Marine Enterprises, Inc., www.parker-marine.com.

Cape Cod Oyster Skiff Particulars:

LOA designed 14′

LOA as build 15′

Beam 4’3″

Draft board up 9″

board down 2′

Sail area 75 sq ft

Weight 150 lbs

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.