Was it time for another boat? In the 1980s, it was a 16′ sailing dinghy that awakened my wife Barbara and me to the beach-cruising pleasures of the San Juan Islands in Washington’s Puget Sound. In the ’90s, it was a 19′ lug-rigged double-ender for oar, sail, and outboard that extended cruising to Desolation Sound. Then came a 20′ catamaran, sporting a wing mast with square-topped mainsail, that got us inside a comfortable cabin while offering exciting sailing in moderate conditions. But as years went by, sitting out in the weather and hauling sheets took its toll. Sailing was exciting when the wind was up, but boring in light summer winds. Why bother with sailing if we could motor at 10 knots? Was it time for a gasser?

And so it was, and we decided upon the Eco 5 Power Cat by Bernd Kohler in France. Its narrow hulls, wave-piercing bows, space-age profile, and three-tone color scheme really made it a looker. At 5.5 meters, it was about the same size and accommodation as our 6-meter sailing cat, and still trailerable behind our compact SUV. The twin 5-hp outboards specified in the plans were to drive the EcoCat at an economical 10 knots and spin it around in circles. Having them mounted on the transoms should eliminate weed pickup, as well as the between-hull wave buildup working against a centrally mounted outboard. I ordered plans, and the digital files came quickly via email.

The plywood-on-frame EcoCat is simply built, using chines sprung around widely spaced bulkheads. I opened the DXF files on an older Mac Cube still running Drawing Board CAD from Ashlar Vellum. With CAD, I made some design changes for a bit more cabin headroom, bigger windows, storage lockers forward, and extended cockpit sides complementing the cabin profile.

Ron Mueller

Ron MuellerThe Eco Cat rests comfortably on the cobbles between tides. There’s room aboard for an inflatable kayak when a dinghy is required if the Cat’s at anchor.

Once I had the design tuned to suit our needs, I nested parts for economical use of plywood sheets, created a tool path for the ShopBot CNC router I’d used for our rowing-shell kit business, and quickly cut out the parts from 6mm plywood. It sounds complicated, but it’s actually similar to laying out parts by hand—but with parts cut far more accurately, with beautiful, fair, and smooth curves everywhere. I milled clear Sitka spruce to dimension, scarfed it to full lengths, rounded edges, and precoated everything with epoxy. This self-made “kit” made for very fast building.

The building jig had only one temporary form; all other forms were bulkheads that remained with the hulls. The hulls were built upside down, planked, and even finish-coated with graphite-infused epoxy—later I’d paint above the waterline. The 6mm planking was patterned on the hull, as the actual faired shape may be a bit different from a CAD plate expansion, then glued in place and trimmed. The hull and side-panel sections were joined with butt blocks that added stiffness in way of the temporary bulkhead. After I flipped the hulls upright and aligned them, I fit the deck—scarfed 12mm plywood. The cabin sides and top were built up with two layers of 4mm ply. It took just four months for me to complete the construction of the hulls and cabin.

The partially finished boat looked great, and I decided to spend the big money for a two-part paint sprayed on by a professional, thinking it would be done quickly. Wrong. It was another six weeks before the boat was back for outfitting. The plans showed a windscreen here, a galley there, a steering wheel, and twin outboards—but no details. It was just another challenge to work through.

Ron Mueller

Ron MuellerThe two small outboards were a good fit for the twin hulls, but didn’t provide adequate power.

Remote steering and motor controls for twin outboards is very routine for a monohull, but not for tiny twin 5-hp outboards on a catamaran! Time to improvise. A tiller bar, supported on nylon bushings, was hidden in the cross beam with a mechanical steering cable connected to the dash-mounted steering wheel. What a challenge it was just to have twin motors on a little catamaran.

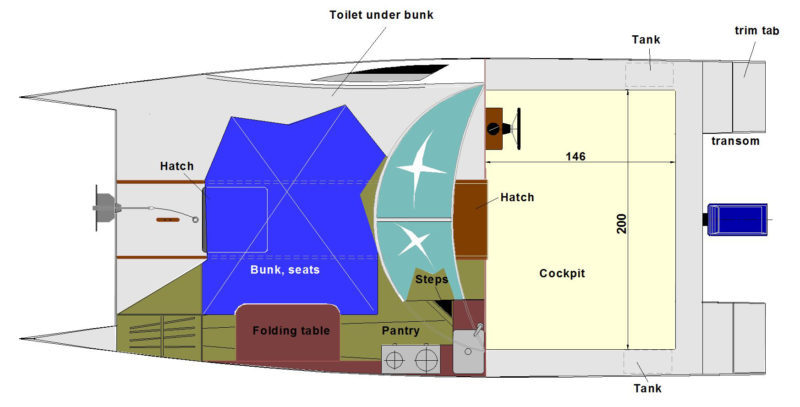

Another professional I hired designed an excellent canvas dodger, back panel, and semi-rigid windscreen that really complemented the design. Barbara and I could now cruise, completely protected from wind and rain, sitting in comfortable captain’s chairs. The 6′ x 8′ cockpit is our living room at anchor, doubling the EcoCat’s enclosed space. A Yeti cooler, good for five days, stays in the cockpit as a table or extra seat. An Origo two-burner alcohol stove eliminated complicated propane systems. We use a lightweight 32-amp-hour starting battery, not for the pull-cord-start outboards, but for powering LED lighting and an iPad for music and charts with the Navionics app. We only need the instruments powered up while we’re under way, so the outboards’ 6-amp charging outlets supply power directly to the instruments and charge the battery at the same time. No shore power is needed. Simple systems for a simple boat—its name, JUST ENUF, serves the cat well!

Ron Mueller

Ron MuellerThe Cat’s shallow draft and twin hulls open up options for anchoring in shallow coves. If the bottom is even and not too rocky, grounding out during a midnight low tide isn’t a problem.

During the boat’s first season we took a two-week cruise to British Columbia’s Broughton Islands. The cruise covered hundreds of miles, and we alternated between being the only boat in a secluded cove and being surrounded by the warm hospitality of wilderness float marinas. A comfortable 80-mile range and top speed of 10 knots allowed us to do plenty of exploring without concern for time or fuel. The EcoCat is comfortable in sea conditions of 2′ short, steep chop and can confidently deal with far rougher conditions.

Ron Mueller

Ron MuellerHaving the lines of the Eco Cat in CAD files simplifies making alterations like raising the cabin roof to provide standing headroom.

This 8′-wide catamaran offers the stability and seakeeping of a far larger boat. There’s never a problem grabbing for a hot pan when another boat, zipping by to look at JUST ENUF, leaves its wake for us. There is plenty of room with a hanging locker and two cuddies for each person. Sleeping bags with integrated mattresses make a very comfortable double. When bags are folded over during the day, the large padded bridge deck area is very comfortable for sitting, cooking, and just hanging out. The starboard hull has a cushioned canoe seat atop the porta-potti. Just forward is hull storage for an inflatable kayak or two folding bikes and other bulky gear. The port hull has standing headroom at the sink and sit-down room for meal preparation with a flip-down table for dining.

Ron Mueller

Ron MuellerA single 20-hp outboard can outperform twin 5-hp outboards. Just behind the motor’s shaft you can see one of the extensions added to the hulls to improve the trim with the greater motor weight. The custom-made canopy doubles the Cat’s sheltered space.

The twin 5-hp outboards proved to be not enough power. They had no top-speed potential, pull-cord starting, and were noisy, especially with the steering linkage rattling between them. Worse, the tiny props had so little bite that docking maneuvers were a constant challenge. A repower with a single Yamaha 20-hp outboard yielded a 10-knot cruising speed, 15-knot top speed, and the same fuel economy as the twin 5s: 1 gallon per hour at any speed. Electric start, 6-amp charging capability, and a lightweight battery competed the package. A 1′ extension added to the stern of each hull helped offset the additional weight of the larger motor and its under-deck 12-gallon fuel tank. Docking was no longer embarrassing, and we could now talk while running 10 knots. The rougher the water got, the faster and smoother we would go. Life was good.

Christopher Cunningham

Christopher CunninghamA hatch in the foredeck provides access to the bow for anchoring.

But as most of the weight was still aft with either engine arrangement, the EcoCat still squatted underway. One day, Mike Snook—experienced with super-large, high-speed Australian catamarans—suggested transom wedges and end plates as the cure. A 1″ x 4″ wedge was added like a trim tab to the each stern with skeg-like end plates added in line with the sides of the hull to contain the flow. The cat’s tracking was better, even with the previous centerline skegs removed. Trim was now level with clean entry and a very smooth exit. After a prop change, we had the same top speed with cruise speed reduced by 400 rpm for a noticeably quieter boat.

Outboards are designed to mount behind a transom with only the prop exposed below the hull. When centrally mounted on a catamaran, all of the lower unit below the bridge deck is exposed to bow wave convergence with lots of unwanted spray and, perhaps, added drag. We had tried several ideas on previous sailing catamaran but solved the problem on the EcoCat with a hull-mounted streamlined fairing that lets the motor think it’s on a transom.

Christopher Cunningham

Christopher CunninghamThe EcoCat is quite at home in the broad reaches of Puget Sound that lie in the shadow of Mount Baker.

The 10-knot cruise speed for our typical three-day, 50-mile round-trips lets us enjoy island life and not lose one day getting somewhere and another getting back. That’s the advantage of a gasser. It’s all about the destination, hanging out, enjoying a nice hike, being in a special place, especially for my wife Barbara and me. My solo trips continue to range farther and wider in all weather conditions.

Could a gasser be my only boat? I still enjoy sailing in other small boats at a rendezvous or big sailboats with friends. I’m on the water most days, year-round, rowing my wherries or open-water shell. The EcoCat takes me comfortably, in safety, to far-off destinations that I would not choose to get to under oars or sail. I’m going to keep my EcoCat!![]()

Ron Mueller continues to design and build small boats and still rows most days in Bellingham, Washington. He started whitewater kayaking in the late ’60s, sailing in mid ’80s, and rowing in the ’90s when he founded Wayland Marine. Ron designed and built the Merry Wherry kits and was the Northwest dealer for Alden Ocean Shells and Echo Rowing until retiring in 2010.

Eco Cat Particulars

[table]

LOA/ 18′ (5.50m)

Beam/8′ 2.4″ (2.50m)

Draft/8.7″ (0.22m)

Weight/606 lbs (275 kg)

Capacity/1350 lbs (620 kg)

Power/15–20 hp

Construction/Approx. 400 hours

[/table]

Plans for the EcoCat, with a digital manual and 16 pages of drawings as BMP or DFX files, come from Bernd Kohler at K-designs. A kit is also available.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Monthly readers would enjoy? Please email us!

I would really like to see a drawing of the modifications mentioned in the text. It sounds like the end product was significantly different from the original design.

Tim, JUST ENUF is built exactly to the furnished plans. Obvious additions were the cockpit sides and transom extensions when repowering. Plans are furnished as DXF files which may be printed out for “manual parts layout” or modified in CAD for CNC cutting. I hope this helps.

Form definitely follows function on your well built boat. The 20-hp outboard was a great idea and so were all of the modifications to get everything right.

Pete, thanks for your kind thoughts. Looking forward to seeing you on a Salish Sea beach soon!

I really enjoyed the article in the March issue of Small Boats Monthly about Ron Mueller’s JUST ENUF. Ron’s boat never fails to draw all kinds of attention when he’s pulled out on the beach or running with a group of other boats up here in the north Puget Sound, and looking carefully at his superlative build, one can easily see why. Though I am somewhat of a “traditionalist” at present, this boat looks like it could very well be in my build list sooner rather than later!

I love seeing articles from other Salish Sea folk. The photo with Mount Baker (Komo Kulshan is the name given to it long ago by the Lummi people) in the background is part of my life.

Vince, twins seem desirable but two 8.5-hp motors would use noticeably more fuel then a single 17-hp motor. Remote control would lend itself to a autopilot but complicated. Remember that each catamaran hull has a different turning radius in a turn. My previous sailing Jarcat had rudders set up with Ackerman steering (like a car). That’s probably not really needed for outboards. Just a thought.

I like the look of this craft. What would be the result if you went to twin 8.5-hp outboards which have the electric start and hardware to do twin rigs with remote control? Still the design appears to have a lot going for it. Enjoy it!

I’m just wondering if the deadrise at the end of each original hull was maintained on the 1′ extensions and if so, how the trim tabs were installed.

Mike, deadrise was just flowed out. The trim tabs are a solid wedge at the end of the hull about 4″ long and 1″ thick. An end plate (in line with hull side) contains the water flow for greater effect. The end plate is a skeg-like shape about 12″ by 4″ that provides better tracking than the original skegs on the keel centerline.

Most of the changes Ron made to the design—the hull extensions and other modifications—are incorporated in the plans. There are many ECO’s sailing world wide and it is my policy to update the plans to improve my designs. That applies not only for my ECO line of boats, but the others as well.

By the way, I leveled out the deadrise of the extension to 0°.

Do the plans show the unique assembly method in case a builder wanted to have the parts CNC

cut? Is the interior of the cabin also coated with epoxy?

Most parts were pre-coated and sanded (at least one side) prior to assembly. The plans are DXF files for display and would need to be, at least, nested for a CNC tool path prior to cutting. After importing to a CAD program, I added an inch in cabin height. Enlarged the windows, laid out cubby holes in the forward bulkhead and designed the cockpit sides with the same curvature used for the cabin. This is a real timesaver and provides great accuracy when having symmetrical parts and provides very smooth curves. The planking and cabin top is best (and easily) laid out directly on existing structure rather then CNC cutting. The construction was completed in just four months while attending to my normal business of selling rowing shells and making kits of same. Painting and canvas was “sent out” and fitting out was, at least, another month.

Thank you very much.

What is the contraption mounted on the forward hatch?

It’s a Nicro Solar Vent Fan. It runs mostly 24/7 as long as its self-contained battery is charged. There is enough leakage through the companionway hatch to keep the cabin dry during winter storage and summer nights when we’re sleeping aboard. We usually slide the main hatch open an inch or two at night (the dodger protects it from rain), and latch the foredeck vent hatch open rather the use the fan. Although fans may be quiet at first, they do develop a bit of noise after a few years.

Thank you.

I did some measuring. I wouldn’t have the ceiling height to flip the hulls over. Is there a real problem building them separately?

Walter, good news, the hulls are built separately. While the hulls were still upside down, I coated them with three coats of epoxy mixed with graphite powder. Those are the black surfaces in the video. This graphite/epoxy mix becomes “bottom paint” and is quite UV resistant, and does not need further painting.

The hulls are then rotated upright, aligned, and a 1/2″ plywood deck is glued to join both hulls. Everything else is built up from this deck—no need to turn the boat over! All of the painting is done from the waterline up. You could paint the bridge deck underside and inner hull sides while the boat is on a trailer.

What brand of windlass was used on JUST ENUF?

An 11-pound Bruce anchor with 10′ of chain is quite easy to haul with an arm-power winch while standing in the forward hatch.

I was looking at the thing below the hatch. Again, thank you.

Appromately how many sheets of plywood were CNC cut?

CNC cutting was used for all bulkheads, frames, cabin sides, cockpit sides, and interior trim— perhaps 10 sheets. The advantage of CNC is symmetrical parts, identical parts for both hulls and very smooth curves and cutout radius. When I had it (now retired six years), my ShopBot was the power tool of choice. Whatever I drew, I could cut and it would fit! Really miss it for my infrequent annual boat building project.

PS: The “thingy” below the hatch was a simple anchor bow roller.

Ron,

Thank you very much for the information. I have found a local shop that has two ShopBot machines with the capacity of 66″ x 122″.

Greetings Ron, and congratulations on a well built project with very intelligent, yet simple modifications. My question is: Why were not twin 10-hp outboards considered when the twin 5s were insufficient instead of the single 20? Weight, perhaps? And could not the weight vs performance equation also be solved with transom trim tab re-engineering or re-positioning of gas tanks, etc?

Love this boat. I am in Biscayne Bay, Forida. We get a chop, we get wind, squalls, hurricanes, etc. It’s a very open bay, but then we get to cruise to the Keys, the Everglades archipelagos, and a million places to explore and gunkhole. I have owned several sailboats here, all with retractable keels—a must if you’re on the bay and want to get off the beaten path of all the Olympic and Biscayne Bay Yacht Racing Association regattas.

Twin 5’s were specified as it was to be a EcoCat. The Honda 9.9 weighs on or about 100 pounds. The Honda rep insists that a single outboard (equivalent in HP to two twins) will always be more economical. I’d suggest today’s best choice would be a Suzuki 25, about the weight of the Yamaha 15/20. It’s said to be more economical and quieter. They sell a 30 (same block size) in the US but it only comes with power trim/tilt so the bracket would be dragging in the water. I hope this helps.