SBM

SBMThe leather is stiff enough to push water forcefully and supple enough to keep from marring the boat’s finish.

Once upon a time the boat sharps on the Delaware River were sailing 15 footers with sail areas running to 400 sq ft. No self-bailers, no buoyancy tanks, no crash boats. When they capsized they had to right the boat, swim it to the bank, and bail. Bailers had to float and not damage the lightly built hikers, tuckups, and duckers. Wood and leather did the trick.

Joe Liener, who was running the wooden boat shop at the Philadelphia Naval Yard before he retired, taught me about duckers and about their bailers. A wood-backed leather scoop bailer gets into corners, doesn’t damage light framing, and can be plucked out of the water when you lose your grip. You can bail faster than a pump and, shaped right like any fine tool, the bailer is a pleasure to use. The handle is turned so you have a nice round fat part in your palm and it is angled just right so you can hook your thumb over the wooden back.

Ben Fuller

Ben FullerThe lathe-turned handle is set into the bailer’s back at 85° for a more comfortable grip.

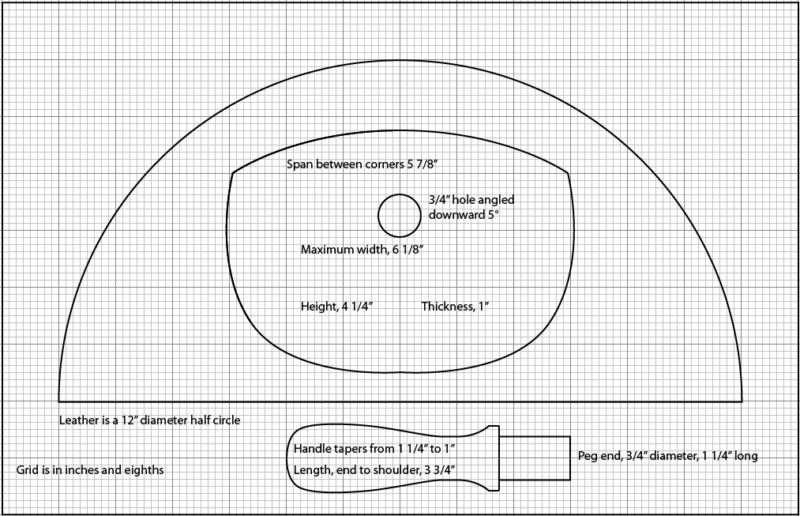

Making it is pretty easy The back ought to be a good 1″ thick and shaped like the stern of a catboat: a bit of flat on the bottom with some tumblehome at the top to help stiffen and support the leather. Cut out the back, then position and bore the handle hole. Angle the bit about 10 degrees. Make a pattern to mark out the leather; a thin plywood template will give you a solid edge to guide your cut. To do the handle, you’ll need a lathe. Before modern glues, the handles were cut where they went into the hole and wedged like an axe head. You can use a straight-sided handle but it’s just not as nice in the hand and you’d need to cut a mortise instead of boring a hole. The leather should be the heaviest you can find. Copper tacks fasten it to the back.

Scoop bailing is easier if you don’t have floorboards or can take up a section. The Delaware builders used to make removable floorboards, called floor flats, in three sections. Two ran either side of the centerboard or daggerboard trunk and one was aft, leaving a frame bay clear side to side just aft of amidships. These were held together by cleats on the underside and had turn-buttons to keep them in place in capsize. Old drawings show a two-handed bailer with a leather scoop bigger than mine but the one hander is all you need to deal with rain and spray that gets aboard.

Ben Fuller

Ben FullerEven after 40 years of use, the author’s bailer has lots of life in it. Unlike a cut-off plastic bottle, it won’t slide around after it has been tucked away.

I’ve had my bailer as long as I’ve had my ducker, a few years short of 40. I’ve releathered it and repaired the handle after using it to bang some blocks of ice out of the winter dory. It also works well for clearing snow. When rainy days put a few inches in the bottom, using the bailer is kind of fun. A hundred scoops with the right hand, another hundred with the left, seeing if I can bail fast enough to get a second scoop in the air before the first one hits the water. It’s my warming exercise before rowing.![]()

Ben Fuller, curator of the Penobscot Marine Museum in Searsport, Maine, has been messing about in small boats for a very long time. He is owned by a dozen or more boats ranging from an International Canoe to a faering.

SBM photographs

SBM photographsThe parts of the bailer, ready for assembly. Note the saw kerf in the peg end of the handle. The dark lines on the handle are made with a piece of wire wrapped halfway around the handle while it is spinning on the lathe. Friction chars the wood.

The hole for the handle is drilled at 85°. Careful repeated saw cuts get the flange of to sit flush against the back.

A wedge locks the handle securely in place. The wedge is as thick as the kerf is wide at its narrow end and about three times as thick at the other end. After driving the wedge home, saw the peg off flush. If you’re using an unyielding hardwood like maple for the bailer’s back, flare the hole with a rat-tail file to allow the handle’s peg end room to spread and lock.

Pilot holes drilled in the leather and bailer back will allow you to hammer 3/4″ copper tacks in without having them buckle or hook around in the wood.

An occasional application of tallow will protect and preserve the leather.

The bailer will hold about 3 cups of water, but will “throw” almost twice that.

Bailing as if it matters can move about 25 gallons per minute.

More interested in using the bailer than making it? Rodger Swanson, whose trailer review appears in this issue, offers them among his line of rowing accessories.

You can share your tricks of the trade with other Small Boats Monthly readers by sending us an email.

Ben was kind enough to allow me to take a pattern off his bailer a few years ago. I’ve made several for friends and customers, all of them well pleased with this nifty item. If you follow his instructions, you will have a great result that’s super efficient. I find that vegetable-tanned beef shoulder leather works the best.