Sam Devlin’s Candlefish 13 began with a client’s detailed request for the design of an outboard skiff suitable for the lakes of Alaska’s Far North. It had to be light enough to lift up over the cab of a one-ton pickup truck towing a fifth-wheel trailer, narrow and short enough to fit on the roof rack, and as stable and as spacious as it can be within the restrictions on length, beam, and weight. Sam drew up plans to his customer’s specs and in the process imagined how he might adapt the design the boat for his own use: “a couple of weeks of moose hunting on a far northern lake with my friends Sven and Ollie.” To that end, the Candlefish 13 he’d build for himself would be able to carry three successful hunters and a half ton of moose meat, and still have about a foot of freeboard. When I took Sam’s Candlefish out on the waters of South Puget Sound on a sunny morning, it wasn’t brimming with camo and a carcass, but I wasn’t the least bit disappointed.

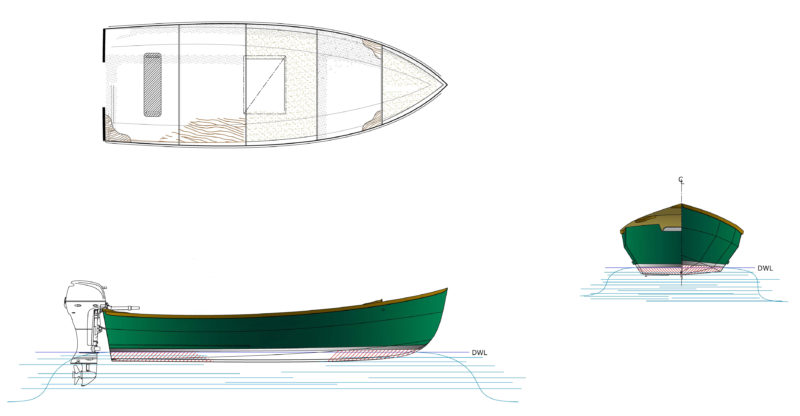

Sam took his inspiration for this little workboat from the pangas he admired on his frequent visits to Mexico. These remarkably seaworthy skiffs had generous freeboard to fight back the chop that came up with the afternoon winds and were narrow for greater efficiency and speed under the power of modest outboards. The Candlefish 13 is diminutive version of the panga with a length of 13′ 4″, a beam of 4′ 11″, and a bare-hull weight of 165 lbs.

All Devlin boats are built stitch-and-glue, a method Sam pioneered back in the late 1970s and ’80s. The thwarts, benches, and bulkheads reinforce the hull and leave the interior free of structural clutter. There’s no shortage of firm unobstructed footing. The cockpit sole is fairly flat, so to keep any water that gathers there from splashing underfoot it’s covered with removable honeycomb rubber mats.

all photographs by the author

all photographs by the authorThe large compartment amidships keeps the cargo clear of the cockpit and its weight positioned for proper trim.

There is a watertight compartment just forward of amidships. Inside there’s room for tackle boxes, a two-piece boathook, a pair of aluminum breakdown oars, and a 6.5-gallon fuel tank. The tank puts the weight of the fuel, about 40 lbs when full, nearly amidships to help keep the boat in trim. The latch that levers the large gasketed hatch cover down tight and has a hole for a padlock to secure the compartment’s contents.

The cockpit is easy to sluice down with a hose. The forward footwell drains aft through an enclosed tube set in the amidships cargo compartment and into the cockpit and then out through two drains in the transom.

The forepeak has an open compartment for more gear and a deck recessed below the sheer and the bulkhead. Scuppers in the corners drain water overboard, so a muddy anchor, chain, and rode can be deposited there and sluiced down with a bucket of water without making a mess of the cockpit.

Spray-on truck-bed liner provides a thick, tough coating with a bit of texture for a non-slip finish.

The center compartment and side benches offer plenty of comfortable seating for the crew whether they’re enjoying the view or gnawing on fresh moose meat. A stout, bright-finished thwart puts the helmsman within easy reach of the outboard tiller, and its slick finish makes it an easy slide side-to-side to adjust trim or switch hands on the tiller. Ample transom knees provide a sturdy base for downriggers.

The bottom has a keel running aft from the stem and ending about a foot shy of the transom. At the aft half of the hull there are bilge keels at the sides, protected, like the keel, by stainless-steel half ovals. Two wedges, each about 10″ wide, serve as fixed trim tabs and keep the boat from hobbyhorsing with a light load aboard.

Sam uses spray-on truck bed liner for interior finish of many of his open boats. It looks good, is tough as nails, and provides good traction without wearing through your britches or elbows. He has used it on the exterior of this particular Candlefish too, an experiment that has been running for three years now. The texture likely adds some drag that knocks a bit off top end speed, but Sam hasn’t found that perceptible enough to change the finish to something smoother. I found very few signs of wear in the finish, even on the bottom. There was a scuff forward, a few small nicks on the corner at the bottom of the transom, but nothing that had come close to penetrating through to bare wood.

A deep gouge might be the only thing to convince someone that the boat is made out of wood. Sam is passionate about wood—“It’s God’s way of keeping me working every day”—but he’s practical about it. In a workboat it’s primarily a structural material, and he’s going to protect it with a durable, low-maintenance finish. I don’t punish my boats with hard use, so I’d opt for a slick exterior. Sam does flawless work with smooth, glossy, Awlgrip finishes, and I’ve often had to restrain myself from offering the dubious compliment of comparing it to production fiberglass and gelcoat. If you build your own Candlefish, you’d be at liberty to gussy it up with more brightwork, but the boat has an appeal that’s more than skin deep. Sam has an artist’s sensibility (his watercolor paintings can attest to that), and he designs boats with the form as the eye candy.

While the original design had to meet the customer’s request for a cartoppable boat, Sam has never been a fan of cartopping: “It’s hard on the boat, hard on the operator, and a miserable way to go.” I’d agree. My 85-lb decked tandem canoe is at the limit of what I can manage to get on and off my roof racks by myself. A trailer is a better way to transport the Candlefish with a great savings in time every time you launch: Your gear can stay aboard and the outboard can remain attached.

Sam’s Candlefish, the one you see here, serves as a utility skiff for his 37′ converted salmon troller JOSEPHINE. The skiff’s padded gunwale guard protects the mother ship when coming alongside, and its narrow bottom and bow eye, placed well down on the stem, contribute to its good manners under tow. When Sam and his wife are cruising Alaskan waters and JOSEPHINE’s at anchor, often in the company of two other couples aboard their own motor cruisers, he uses the Candlefish to shuttle gear and people: “I can carry all six of us and the dog in a hot minute.”

With the Candlefish’s 20-hp outboard at full throttle, Sam Devlin skims smoothly along at over 20 knots.

With a 20-hp Yamaha four-stroke outboard powering the Candlefish, she gets up and a plane with one person aboard in about 4.5 seconds and then with the throttle wide open flies along at 20½ knots. With two of us aboard, the Candlefish 13 topped out at just over 17 knots. She tracks well at all speeds and banks quickly and powerfully into turns: I quickly learned to use a soft touch on the tiller. A slight angling of the tiller sets the inside chine down, and the Candlefish carves smartly around.

The Candlefish maintains a level trim and good visibility at low speeds thanks to the centrally located cargo compartment and the fixed thwart that keeps the helmsman well forward of the tiller. The bow rises only briefly as she climbs up on a plane, and the skiff levels right out again.

Empty, the Candlefish 13 draws just 4 ½”. Throw in half ton of cargo and crew and it will draw about 9,” leaving plenty of freeboard.

The bottom is 36″ wide at the transom and not much wider amidships, so with just me and a light load of essential cargo in the center compartment, the Candlefish is a bit tender but she has plenty of flare and stiffens up as she heels. Settled deeper in the water with a heavier load, that moose for instance, she’d care much less where I planted myself.

Sam offers plans and patterns on paper and in digital format. He estimates the cost of materials for a do-it-yourselfer at around $850 and the time to build at 200 to 250 hours. Kits and finished boats are produced by Devlin Designing Boatbuilders upon request. They’ll use British Standard 1088 Marine Grade Plywood, 9mm (3⁄8″) for the hull and 18mm (3⁄8″) for the bulkheads. The exterior is sheathed with Dynel fabric and epoxy. The lumber that goes into the gunwales, seat edges, keels, breasthook and knees is either Port Orford cedar purpleheart or Honduras mahogany (plantation grown in Fiji).

The Candlefish 13 is a trim little skiff that packs a lot of potential into her short length. Lively running light and with the load-carrying capacity of a half-ton pickup truck, she’d be no stranger to work or play.![]()

Christopher Cunningham is the editor of Small Boats.

Particulars

LOA: 13′ 4″

Beam: 4′ 11″

Draft: 4 1⁄2″

Displacement: 445 lbs

Dry Weight: 165 lbs

Recommended outboard engine: 6–20 hp

Plans, kits, and finished boats for the Candlefish 13 are available from Devlin Designing Boat Builders.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Monthly readers would enjoy? Please email us!

Another great small power boat is Phil Bolger’s Diablo. I have had one for about 3 years, and I think it’s one of the best small boats out there. With just me aboard mine will do about 20 kts powered by an old 15 HP Evinrude 2-stroke. Slow it down, and it is a great rough-water boat and very dry for an open boat. Plans and full-size patterns are available and instructions are in Dynamite’s book, Build the New Instant Boats. It’s fairly easy to build, there are a lot of them out there.