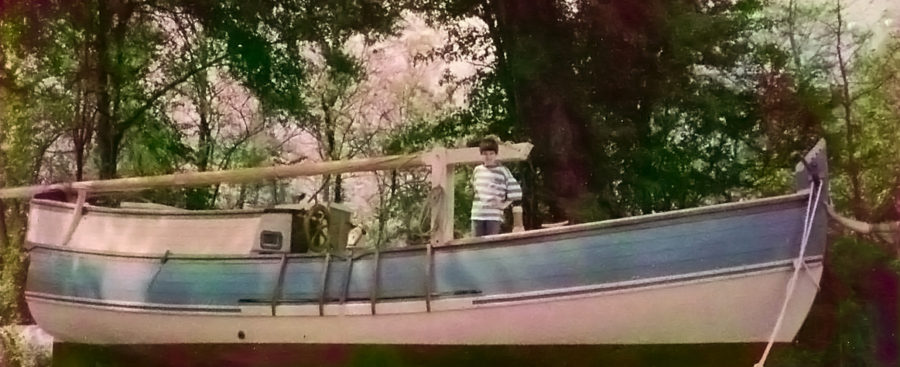

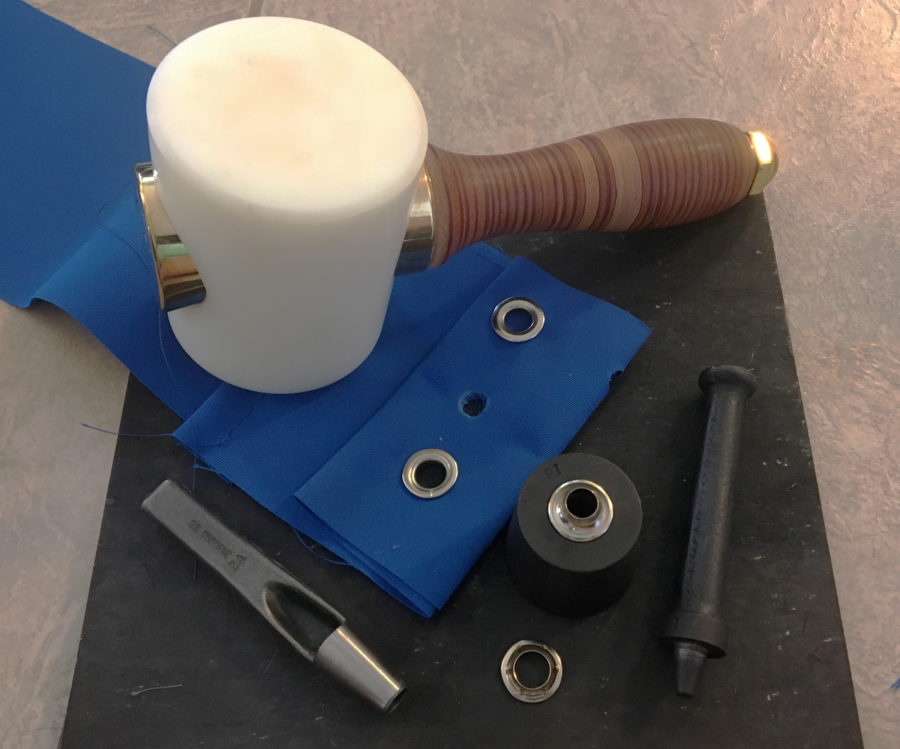

Insignia cloth was used to make the skull and crossbones on the sail as well as the racing stripes on the deck. photographs by the authors

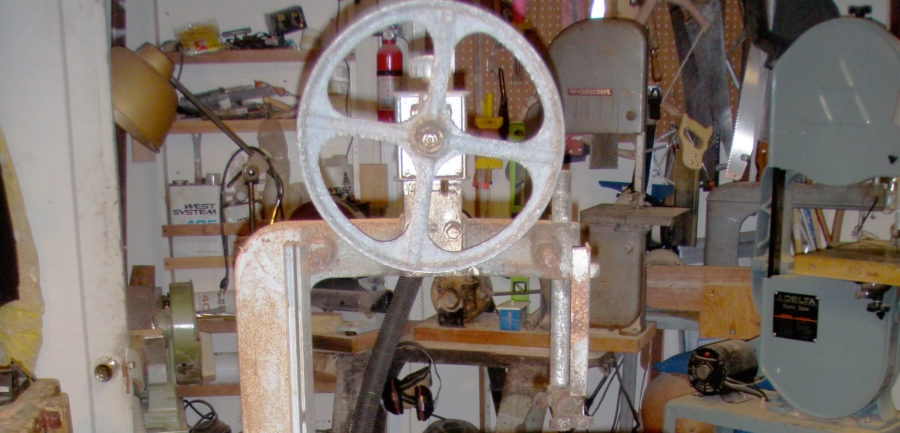

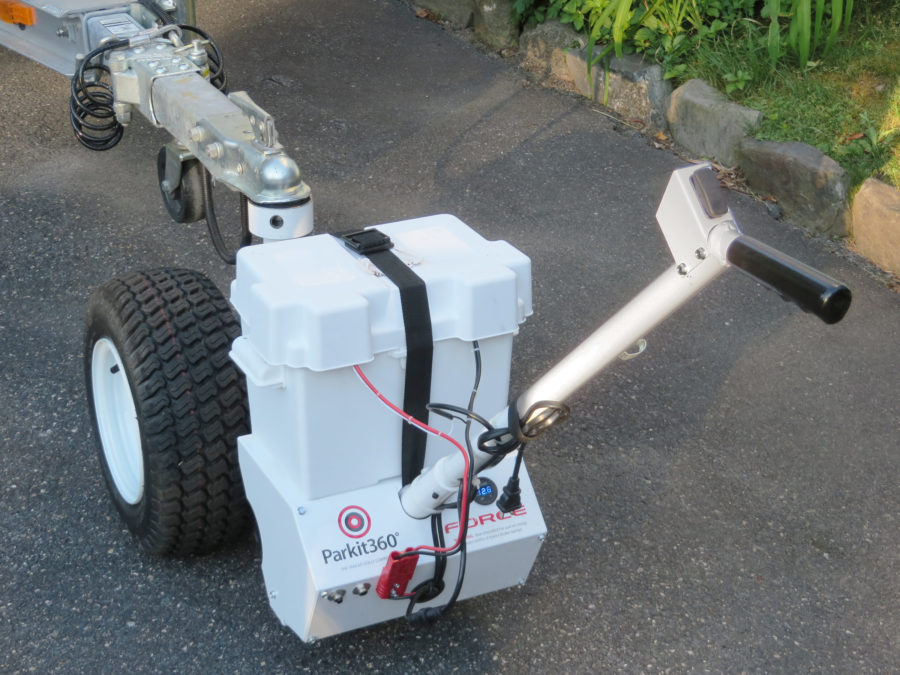

photographs by the authors

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.

Comments (2)

Leave a Reply

Stay On Course

Great article, very interesting to know that adhesive sailcloth doesn’t require stitching and stays put. Love the skull and crossbones. I’ll have to steer well clear of Pensacola Bay if I want to hang on to my pieces of eight.

Good info. I’m needing to do this to some sails so I can get my insignia/logo on the sail.