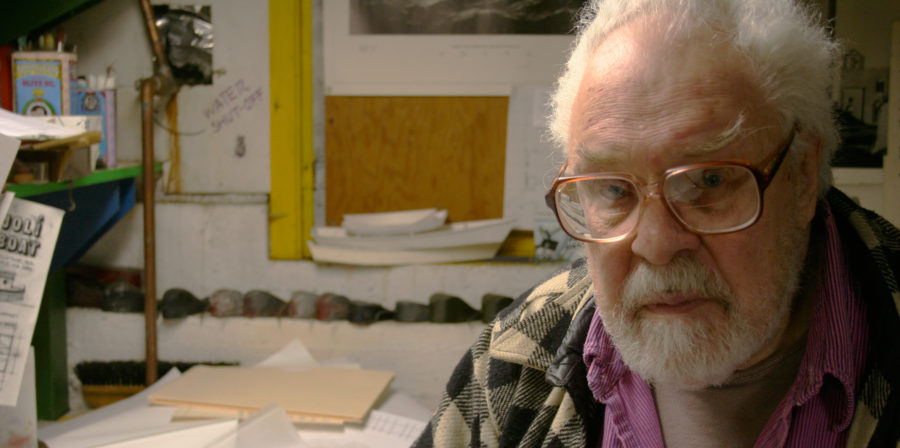

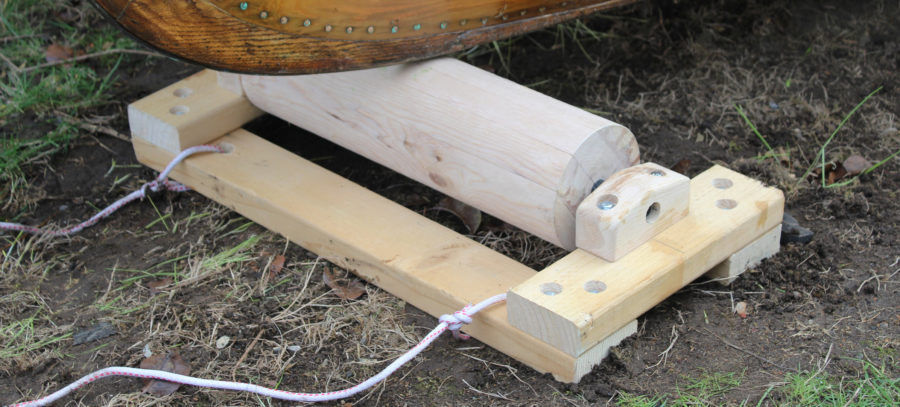

When I read this issue’s story about Reid Schwartz, I knew how he could have fallen into the thrall of birchbark canoes. It happened to me in the early 1990s when I was a speaker at a sea-kayak symposium on the northwest coast of Lake Superior in Grand Marais, Minnesota. One of the other presenters was a birchbark canoe builder. I don’t now recall his name, but my research suggests that it was quite likely the late Walter Caribou, an Ojibwe who had lived in Grand Portage, just up the lake from Grand Marais. He invited attendees to visit his shop and there I was quickly fascinated by the process of building a strikingly beautiful vessel from sheets of birchbark and other materials harvested from the surrounding forests. Walter explained how the bark can be harvested from a standing tree without fatally girdling it and how roots are gathered, scraped clean, and split in two for lashings. The large basket is in the style of a wild-rice winnowing basket; the smaller one was made to a pattern given to me by an Ojibwe bark-canoe maker. For the sheath, I just folded a piece of bark around the knife, cut away the excess, and laced it with split root.

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.

One thought on “Bark”

Leave a Reply

Stay On Course

Thanks for this deeply connecting article, Chris. We could learn a lot from indigenous peoples all around the world about respect and gratitude for the basic needs of life.

Wayne McCallum,

Australia