Riley Hall was born and raised in Gig Harbor, Washington, a quiet town nestled around a narrow, mile-long inlet that shares the town’s name. The shoreline is bristling with piers and the water is dotted with boats at anchor. Surrounded by boats, it was only natural that Riley began building and working on them at a young age. He kept at it through high school and began restoring a 1940s-vintage canvas-covered cedar-strip rowing boat at home. For his senior-year project, he chose to work at the Gig Harbor BoatShop, documenting and disassembling hull #2 of the Ben Seaborn–designed Thunderbird.

After graduating, his interest in the restoration of old boats led him to move across the country to Rhode Island to study at Newport’s International Yacht Restoration School (IYRS). While enrolled there, he spent winter evenings and weekends restoring a 1963 Snipe. After graduating from IYRS in 2012 he got a job maintaining and restoring mostly classic racing yachts at Baltic Boatworks in nearby Bristol.

During the time he had been on his career path—restoring large yachts and working boats—Riley had been toying with the concept of small boats built from a single sheet of plywood. He designed and built his first one-sheet rowing skiff while home for Christmas in 2014. He had brought the paper patterns for the skiff with him to Rhode Island and shared them with Don Betts, a local boatbuilder who had built a 31’ six-oared Cornish gig, and the one-sheet skiff Don built led to two more, built with the help of a group of Sea Scouts.

After about six years at Baltic, Riley moved back to Gig Harbor in 2018 to take a job with Harbor History Museum. There, as a restoration/preservation specialist, he was put in charge of the volunteers restoring the 65′ purse seiner SHENANDOAH, which was built in Gig Harbor in 1925.

The SHENANDOAH project kept Riley busy during his working hours but left him with some free time and a creative impulse to design and build something new.

Working in the studio above his parents’ garage, he built three more one-sheet rowing skiffs, trying new iterations of the concept each time. The 2.5-hp four-stroke Yamaha outboard he had for his 16’ Calendar Island Yawl set him to wondering what kind of speed it could produce with a boat made of a single sheet of plywood.

Cocktail Class Racers naturally came to mind. Developed in 1939, they’re outboard-powered racing skiffs with a length of 8′ and a beam of 4′, just like a sheet of plywood, and limited to 6-hp motors—8 hp for racers who weigh over 200 lbs. They top out at 26 mph, far beyond the potential of Riley’s 2.5, so, with racing off the table, he was free to lavish attention on aesthetics and let visual elements from racing kayak, vintage bicycles, Beetle Cats, and ’50s nostalgia work their way into his design process.

Riley Hall

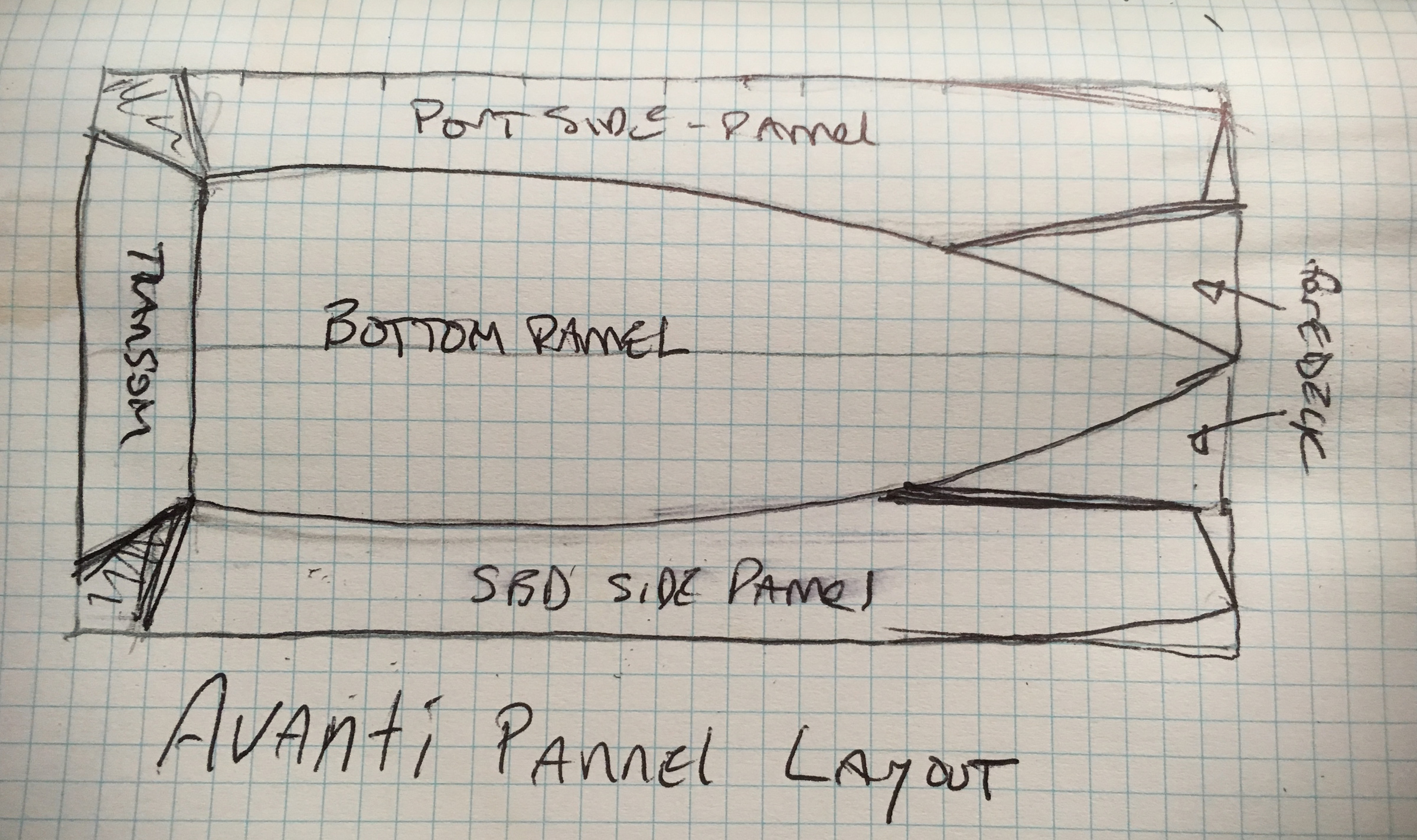

Riley HallIn Riley’s one-sheet scheme, the curve of the sides took their shape from the outline of the bottom.

He started with a wedge shape for the hull: a plumb stem to part waves and a flat run for planing. As he explored the shape with a model of stiff paper, the sides came together in a way that suggested a raised foredeck and stem with a reverse rake. The foredeck required a break in the sheer to sweep down to the stern, which, as Riley put it, “revealed a slightly strange shape, like little ears, between the side and foredeck standing out as rather odd and unconventional. I decided it was similar to what you see on racing kayaks, which look cool and go fast, so why not?”

Riley Hall

Riley HallRiley built AVANTI in the space above his parents’ garage. The room was meant to be an art studio for his father but got hijacked by a climbing wall and a boatbuilding project. At this phase of the construction, the idea of adding fins to the coaming was taking hold.

Riley started construction in a workshop space over his parents’ garage. With the shape established by the model, Riley could take the pieces apart from each other to “expand” their shapes and scale them up on onto a piece of plywood. After cutting the full-sized panels from plywood and fairing the panels, he temporarily assembled them with Gorilla tape, fine-tuned the shape, and used the plywood “skin” of the hull to take measurements for the boat’s two frames.

After Riley had installed the foredeck and a Beetle Cat–inspired coaming, he invited his father, Curtiss, an art teacher at the high school Riley graduated from, for a consult on aesthetics. As soon as he laid eyes on the boat, Curtiss said, “It looks like a Studebaker Avanti.” The iconic Avanti, a high-performance car with a distinctive “reverse rake” on the front end of its side panels, was Studebaker’s swan song, released in 1962 as the company was closing down.

Curtiss’s comparison set the boat’s name, AVANTI, Italian for forward, and pointed to an automotive aesthetic direction for the rest of the project. Riley had been looking to Herreshoff’s boats for a suitable shape for the aft ends of the coaming, but nothing looked quite right on AVANTI. While the Studebaker coupe didn’t have fins, it was produced in the final years of the fin craze, and the combination seemed to work for the boat.

Riley Hall

Riley HallThe name plate is a copy of the one that adorned Studebaker’s Avanti coupes in the ’60s.

For steering, Riley opted for handlebars instead of a wheel. Cocktail Class Racers require that the drivers lean far forward to keep their bows down and they’re forced to wrap their stomachs around the wheels. Riley found a bow fitting at a marine thrift store that could have easily been a classic-car hood ornament; the nameplate his dad made, replicating the one Studebaker put on the Avanti, was the finishing touch.

Kathy Hall

Kathy HallAVANTI sits nicely on the water with the outboard’s 48 lbs and Riley’s 140 lbs aboard.

AVANTI emerged from the garage measuring 7′2″ long with a 3′ beam and weighing just 40 lbs. And with the little 2.5-hp outboard providing the power, AVANTI will get on plane and look good doing it.

Kathy Hall

Kathy HallRiley’s Aunt Stephanie provided the proper headwear and eyewear for sea trials.

As for Riley, whether he’s skimming across Gig Harbor aboard AVANTI, working on SHENANDOAH, or keeping busy with his free time, he’ll be making good progress in the same direction he always has, forward—avanti.

Do you have a boat with an interesting story? Please email us. We’d like to hear about it and share it with other Small Boats Magazine readers.

Is it possible to get plans? Looks like fun.

Andy

I should not have read this. It is too tempting by far. Maybe a bit bigger and 6 hp because I am a bit heavy. Looks like really cheap fun. Maybe one doesn’t need plans.

Yes, please let me know if plans are to be had.

Whoa, way cool! That is one sweet little speedster!

There was an Avanti in my neighborhood growing up, that was just a beautiful car!

Yes – plans please Riley!!

I’ll bet an electric outboard would be cool, and stealthy! It’s short enough to put the batteries at the bow without too much loss of voltage. That might allow a more comfortable riding position.

Yes! Put me 5th in line for plans!

Another request for simple plans, Riley! Looks like a hoot (and I happen to have a little Suzuki 2.5hp engine, already). I’d be happy to give you anything from my site as a return gift (you’re still a climber?).

Hey folks, thank you for your interest and curiosity towards my silly little boat Vespa. At this point there are no plans drawn for the boat as it was developed as I went along without proper documentation. I can make some patterns, take some measurements and develop a basic set of as builds with basic construction details, and see about making those available to folks. For now you can think about acquiring a sheet of plywood 3/16-1/4″ should do and assembling your 1x scrap wood into 1′ , 3′ 4′ and 8′ lengths. Folks heavier than I, with larger outboards in mind, might consider sourcing a 5×10 sheet of plywood and longer lengths of scrap wood.

Hi Riley

If you do make some rudimentary “study plans” available, I would love to acquire them!

Love the boat and design elements you put into it!

Jerry Welch

Really nice. Congrats!

At 6′ 5″ and 220 lbs, I won’t be building anything similar anytime soon. The 10′ sailing dink I built was awkward enough. But I just had to send congrats on the steering bar. Very cool and fitting.

Looks like a ton of fun! I love tiny boats, but they don’t love me. At 5′ 9″ and 215, I’m guessing it won’t plane.

It will with a 5 hp 2 stroke.

Way to go Riley!! Dream and build.

Love this!

Fit’s inside a pickup bed

Go electric!

Bravo!

We understand the envelope can still be pushed !!! Bravo Sir !!!!

Riley, this is a cruel way to get a fella’s mind flying in all directions. I have 2 sheets of 1/4″ x 4′ x 16′ fir marine ply that I have been storing for 30 years. Bought at Edensaw when you can still buy the long stuff. How’s that for getting your mind roaming? Still looking for a project for the panels. I’m in Everett.

If there are any quick dimensions that could be taken off your working model, that would be a great starting point. Thanks!

Just too cool!

Cheers,

Rob