Small boats provide endless opportunity for innovative thinking. We prowled the waterfront seeking clever and aesthetically pleasing solutions to some of the common problems posed by small boats: how to rig them, how to move them, how to stow gear aboard them, how to steer them, and how to live comfortably aboard them.

On the following pages, we present a selection of those details, beginning with an ingeniously outfitted Caledonia Yawl in which Small Boats Magazine editor Chris Cunningham cruises in style with his two children. We hope the ideas presented here will inspire you when it comes time to outfit your own small boat.

Christopher Cunningham

Christopher CunninghamChris Cunningham’s crew enjoys dinner aboard Chris’s 19’ Caledonia Yawl. (Chris is behind the camera, and will join them shortly.) Carefully designed and built details allow this small boat to be comfortable for daysailing, sleeping, and eating.

A Galley in a Box

Here’s a galley in a box that stows neatly aboard Chris Cunningham’s Caledonia Yawl. “I used a wide slip thwart as a base for the galley box,” says Cunningham. A slip thwart is a removable crosswise seating platform that sits on ledges built into the edges of parallel side benches. “When not in use,” says Chris, “the galley hangs beneath the thwart and serves as a seat for rowing or as part of the sleeping platform. At mealtimes the box is flipped upright and set anywhere along the side- bench ledge. With two stoves, tableware, and cookware, the box is quite full and the contents shift little when flipped. I always pack a tablecloth as much to cushion plates and pans as to cover the footprints on the dinner table.” The dinner table, you see, is a repurposed floorboard.

A Floorboard as Dining Table

“A pair of slip thwarts 9″ to 10″ wide and set vertically,” says Chris, “will support a floorboard panel at table height. Holes drilled in the center of each slip thwart accept the ends of a dowel to hold them on edge.” Imagine a trestle table, and you’ll get the idea. “The slip thwarts then can rest on the bench ledges. In my yawl the dowel allows the slip thwarts to be set across the ledges and support the table in its normal athwartship orientation to seat four or more, or with the slip thwarts parallel with the ledges and the floorboards rotated 90° to provide an alternate seating arrangement for two. The latter arrangement allows the diner aft to tend to the helm when the boat’s underway. (Meals I serve while underway are usually limited to downwind runs in light air.)”

An Elevated Sleeping Platform

The same ledges that support Chris’s slip thwarts also support his floorboards, which are raised up to become the sleeping platform. “The space between the side benches will dictate the dimensions of the floorboards,” says Chris. The thickness of the floorboards and the placement of their cleats is carefully planned so the surface of the floor-board–sleeping platform rests flush with the tops of the side benches. The floorboards in the bow of Chris’s yawl are at a fixed height, which is 9″ above the designed height. This extra elevation, due to the flare of the hull, allows enough width for a V-berth; the space beneath them allows some storage. “As high as these floorboards are,” says Chris, “there is little effect on stability when I stand on them, and their broad expanse makes for excellent footing for handling the sailing rig.”

Locker Ventilation

This pleasing silhouette depicting seagulls against the setting sun adorns a locker door on a First Light launch built by Pease Boatworks of Chatham, Massachusetts. The hand-cut detail is not only decorative; it also provides needed ventilation to the locker.

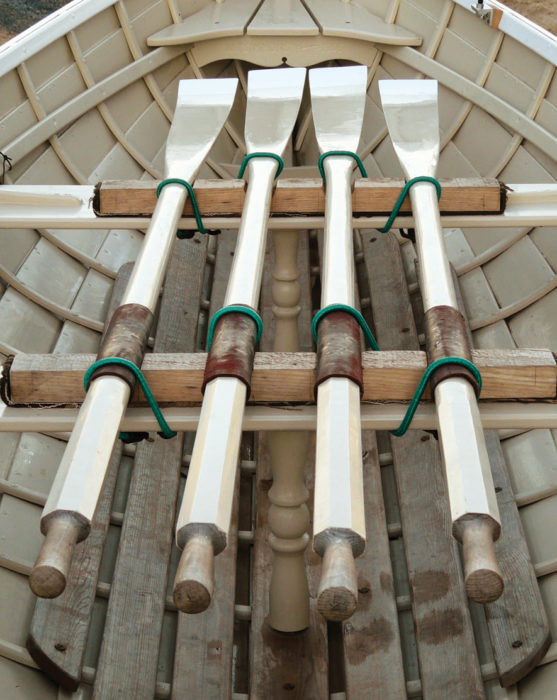

An Oar Cradle

Walt Simmons made this clever oar transport cradle for his Matinicus double-ender (page 96). Two, 2×2s are bored with 2-1⁄4″-diameter holes and then ripped to form half-round cradles. The outside of each cradle is carpeted to keep it from scratching the thwart it rests upon. The two cradles are set on the thwarts, the oar looms are laid into their respective cradles, and then the whole thing is bungeed in place to prevent sliding or shifting during transport.

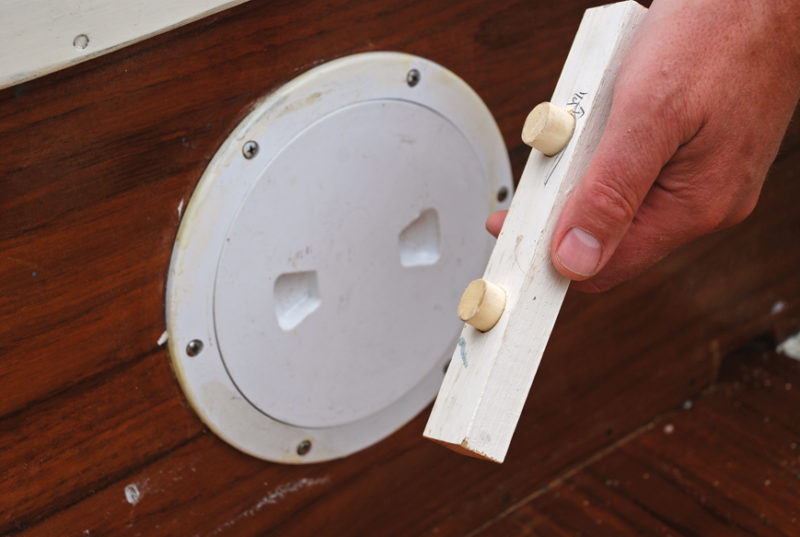

A Shop-Built Inspection Port Tool

Trevor Peterson devised this handy inspection-port wrench for his 16′ Bolger-designed Surf double-ended sloop, BLUE BIRD. His oarlocks were stowed under the afterdeck one day, accessible only by the port, and the breeze was dying. That’s when Trevor discovered that loosening the port’s threaded plate was far harder than tightening it. Some determined effort freed the oarlocks that day, but it also sent Trevor’s mind to thinking about a tool to aid the job. The result couldn’t be simpler—and more effective: Two 3 ⁄4″-diameter dowels are set and glued into holes bored through a piece of 3⁄4″×1-1⁄2″ pine. The dowels protrude from the face of the pine by about 1 ⁄2″, and they do the work that would otherwise be done awkwardly by fingers. The tool also allows for ports to be mounted in tight places where hand function might be restricted.

Steering Linkage for a Yawl

Small yawls with outboard rudders always pose steering problems: how do you work around the mizzenmast? Some use a traditional Scandinavian method of a long push-pull tiller connected to a one-armed yoke on the rudderhead; others use a wildly looping tiller laminated to a great bend to allow it to swing and yet clear the mizzen. This solution uses a cast-bronze tiller yoke connected via low-stretch line to a similarly proportioned rudderhead yoke. Stephen Canright of the San Francisco National Maritime Historical Park developed this system for his own double-ended Nomans Land boat.

Wooden Bailers

These handcrafted bail scoops are nicer-looking than the often-used cut-away bleach bottles for bailing water that collect in the bilges of small wooden boats. The smaller, solid bail scoop is simple to make and fits smartly between a boat’s seat riser and planking when not in use.

A Ridge for the Boat Cover

Standing water on a boat cover can leak and damage a wooden boat in storage. This pole supports a fore-and-aft wire, which keep the boat’s canvas cover elevated, ensuring that water will be shed from it. The pole’s step and partner hold it fast, even in strong winds.

Bow Grating

Near the bow of a boat—in this case, the dory REPUBLICAN built by Capt. Gerald Smith—where the painter and anchor rode are stowed, this removable “bow grating” will help keep the bilge well ventilated while giving wet line a broad drying surface.

Dory Oarlock Keeper

This simple oarlock keeper on a Bolger-designed Gloucester Light Dory is made by cutting a slot in a side-mounting oar-lock socket. Filed and

sanded smooth, the slot allows the twine to pass when the oarlock is slipped into the keeper. Mounting the keeper on a spacer block gives a bit more clearance for the oarlock’s horns, making it easier to set or retrieve the oarlock. When the boat is set upside down over sawhorses for the winter, the keeper works another way: Sliding the oarlocks into the keeper the opposite direction makes them stay tucked up out of the weather.

Oar Keepers

Jonathan Minot, a boatbuilder from central Maine, borrowed from an elegant Adirondack guideboat tradition when building this lovely pulling boat to his own design. Like those famous lake boats, this boat’s seat back for the after thwart doubles as a keeper for the oars, which slip into purpose-made notches. Note that the seat’s top edge is fitted with a brass rub strip to guard against the inevitable times when the blades don’t make it into the notch on the first shot.

Centerboard Rod Pennant

A sailing Beach Pea peapod designed by Doug Hylan of Brooklin, Maine, and built by The Landing School in Kennebunkport, uses centerboard hoisting gear made of bronze rod. The great advantage of the rod is that if a stone jams the centerboard in the trunk, the rod instantly provides something rigid to use to push down on the board to clear the blockage. This arrangement doesn’t allow for fine-tuning the centerboard—it’s either all the way up or all the way down—but racing tactics like slight board adjustments aren’t really the objective for a boat like this one, anyway. When the board is raised, the rod is housed by pressing between two simple bent-bronze keepers; when lowered, a similar keeper stops it from drifting up. A setup like this also saves overall boat weight because the board doesn’t need lead ballast to hold it down when under way.

An Organized Center Console

Boatbuilder Mark Ober of Sorrento, Maine, put a lot of thought and care into the construction of a well-appointed center console for his 22′ Pulsifer Hampton boat. The box-shaped, low-profile addition to the console is held in place by only two screws, and by backing them out—and disconnecting several multiplugs—the entire box can be removed for access. On the underside of the hinged lid, Mark has his VHF microphone, a stopwatch, a digital clock, a pencil, and a flashlight neatly organized. Inside the self-draining box are engine instruments and warning lights, bilge pump switch, the VHF’s main unit, a GPS display, and a depthsounder readout. In case of rain, the console’s lid can be closed to cover the gear. As backup in case of GPS failure, Ober uses a compass with a purpose-made mount that slips under the lid’s handle aligned with the boat’s centerline. By placing the main battery under the afterdeck instead of at the base of the console, he opened up in-console locker storage, with quick access to his fire extinguisher, flare kit, horn, and binoculars. It’s a tight package, neatly organized, and highly functional.

A Well-faired Motorwell

Aboard the Townsend Tern, a small cruiser designed and built by Kees Prins of Port Townsend, Washington (see page 88), this well for an outboard motor—an electric one, in this case—has a clever method for closing off the bottom when sailing. Two doors, operated by lines from the cockpit, close when the motor is kicked up but allow easy opening when resorting to motor power when the wind fails. Being able to close these doors keeps the hull stream-lined when sailing. The system relies on simple technology—bronze angle and commonly available rigging fittings. A car sliding on a piece of sail track mounted on the well side works through a hinged bronze angle to open or close the door. Two lines per door—one hauling the car down, the other up—lead to cam cleats in the cockpit, locking the door either in the closed or open position. The three bronze angles that form the door hinges lie flush with the inside of the plywood bottom planking, assuring that the door will stay flush, as well.

A Box for the Anchor Rode

James McMullen of Emerald Marine in Anacortes, Washington, developed an effective box for keeping the anchor under control on ROWAN, his Iain Oughtred–designed, double-ended Sooty Tern. The box keeps the anchor, chain, and rode contained, and a purpose-built cutout in the floorboards prevents the box itself from sliding around the boat during tacks. Keeping an anchor under control not only keeps it from damaging floorboards and planking, but also can increase safety by keeping the anchor’s weight low and on the centerline instead of off to leeward. The box also keeps the anchor within easy reach when it needs to be set In a hurry. An additional benefit is that the box lifts out for trailering, so the chain doesn’t get dragged across the boat’s nice woodwork.

A Folding Trailer Bunk

For his Washington County peapod, Charlie Chamberlain of Brunswick, Maine, made up an unusual trailering bunk. The hinged bunk folds down so the boat can clear it when being drawn up onto the trailer. The boat settles into a fixed forward bunk and, once the hull is in the right position fore-and-aft, the after bunk swings up and locks into place.

A Rope-Stropped Block

This rope-stropped block made by Trevor Henderson is used to tension the starboard running backstay of FRANCES DE LA ROSA, a sloop designed by J.R. Purdon in the late 19th century, and built by Alex Low and Jon Brown in 2010. Rope-stropped blocks are straightforward to build and to modify, and the rope strop both conceals and secures the sheave axle.

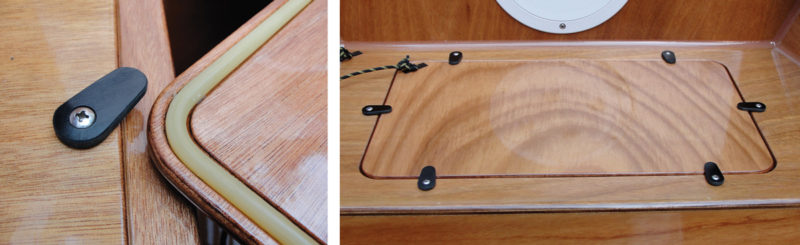

A Watertight Hatch Seal

The words “simple” and “watertight” don’t usually go together, but these hatches in the seats of the PT Skiff are both. Surgical tubing glued into a notch in the hatch lid provides a gasket. The dogs are machined from fiberglass plate and have a thin plastic washer underneath. The fastenings are bonded into epoxy-filled holes in the wooden hatch coamings.

An Under-Seat Locker

Designer-builder John Brooks built an eye-catching glued-lapstrake plywood interpretation of the legendary Herreshoff 12 1⁄2 daysailer (see WoodenBoat No. 217), and in the process devised this clever under-seat locker. The spaces under the forward and after decks of both the orignal Herreshoff boat and the Somes Sound 12 1⁄2 are relegated to buoyancy chambers, and aren’t meant for storage. But a small boat such as this one is kept much more tidy if its gear—unused sail stops, foghorn, flares, hand-bearing compass, docklines, and such—have a home. The space under the seats of the Somes Sound 121⁄2 proved to be a perfect place to tuck all of this stuff, and a locker there keeps it safe and organized.

Flip-out Oarlock

This flip-out oarlock socket increases the effective beam, and thus the oar power, on a 16′ Rangeley Lakes boat built by Tom Regan of Grapeview Point Boat Works. The boat is based on a C.W. Barrett design of 1915, and the hardware is from Shaw & Tenney (www.shawandtenney.com) of Orono, Maine. The otherwise vulnerable socket locks in its rowing position, and is easily unlocked and flipped into the boat for storage and transport.

A Compass Guard

A thwart-mounted compass in an open boat is vulnerable to all sorts of knocks from oars, errant steps, and fouled lines. This simple guard, resembling a mast partner, is part of the outfit of TERN, a 23′ open ketch designed by Tad Roberts and built by a group of recently graduated college friends who made a 10-month expedition in the boat from Lopez Island, Washington, to Ketchikan, Alaska—with no damage to the compass. (See WoodenBoat No. 195 for an account of the expedition.)

Shop-Built Kayak Cart

Brian Bean of Lake Tahoe, California, designed and built both this 19′ kayak and the cart upon which it rides. The cart has a form-fitting carbon-fiber saddle, a wooden axle to which the spoked wheels are lagged. The buckle and strap came from the local hardware store.

Quick-Release Turnbuckle

Here we have a quick-release turnbuckle from Port Townsend Foundry of Port Townsend, Washington (www.porttownsendfoundry.com). This hardware allows for fast setup and down-rigging of an Aurai 17, an Arch Davis–designed sloop (based on his Penobscot 17 design) sold by Callisto Sailcraft of Wenatchee, Washington. Note the deadeye to which the turn-buckle is fixed: It’s attached to a piece of threaded rod that’s nutted on the other end. Remove the nut, pull out the deadeye, and you’re left with an oarlock socket. Very resourceful. ![]()

Oh, this gets the creative juices flowing. Lots of great ideas here, and I’d like to see more! I’m building an 11′ tender to my 32′ sailboat and I love to add as many unique features as I can.

My favorite boat is a Walter Simmons 15’ lapstrake double-paddle sailing canoe, built by Mr. Simmons and purchased at his shop in Maine (I’m not the original caretaker of this amazing boat). So many ideas and so little time! Your wonderful SMALL BOAT DETAILS should become a book. …… I know, I know.