I’ve been using the same five countersinks for decades. While they’re all different—one has a single flute creating a cutting edge and two have a pair of flutes; one has five flutes and another has seven—the one thing they have in common is that none of them works very well. On all of them, the cutting edges of their flutes are square to the circumference, so they scrape rather than cut. And as scrapers, they’re rather crude, lacking the sharpened burr of a cabinet scraper. What’s even worse is that countersinks chatter. The irregularities in the wood’s density cause the countersink to get nudged off-center, and the resulting vibration makes for some odd-shaped recesses that are anything but round. (Countersinks that are attached to tapered bits for wood screws are prevented from chattering by the drill bit. That’s also the case with countersinks with integral pilot tips sized to fit a particular predrilled hole.)

Photographs by the author

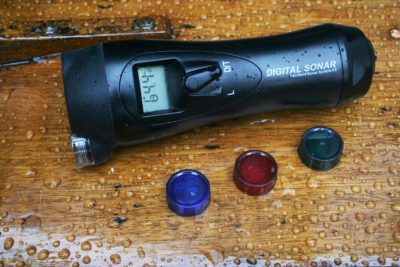

Photographs by the authorThe set I bought came in a padded case. The countersinks are precision tools with sharp cutting edges and are well worth protecting.

Small Boats reader Steele Hinton recently mentioned that there is one type of countersink that cuts cleanly and without chatter, by not having any flutes at all: the zero-flute countersink. It has a smooth conical tip with an upward-angled hole bored in one side. The sides of the hole meet the conical surface at an acute angle, about 45° (the equal of a bench plane’s blade to its sole), so it’s poised to shave rather than scrape. I could hold that edge against pine and oak and carve curls of wood, which is impossible with an ordinary countersink.

The cone machined on a zero-flute countersink may appear to be a simple geometric shape, but it has an important difference. Just as a plane blade protrudes through the sole to cut, the edge on one side of the countersink stands slightly proud of the other edge. This cutting relief, as it’s called, is what makes the countersink work only in one direction, clockwise. A zero-flute countersink cuts quickly and needs very little pressure to make a deep hole.

The holes that create the cutting edges and the exit passages for shavings pass through the heads of the countersinks.

Each of the zero-flute countersinks has a small flat milled on the very tip of the countersink. It can work its way into wood without a predrilled pilot hole, but it makes slow progress and doesn’t pick up speed even when the hole’s sharp edge starts cutting. The countersinks are meant to follow predrilled holes.

The zero-flute countersink does very clean work whether cutting for a screw to be set flush or to be set deep and then covered by a wooden plug. The set of countersinks I bought came in four sizes: 5⁄8″, 1⁄2″, 3⁄8″, and 5⁄16″. The three largest are true to size and make holes that are a good fit for wooden plugs. They have an 82° point, which matches the angle of screwheads manufactured in the U.S. and Canada to the Unified Thread Standard. Zero-flute countersinks are also available milled to a 90° point for fastenings that meet the international ISO standard.

The countersinks can recess flat-head screws flush or bury them for plugs. There are no stops for controlling the depth, so that must be done by eye. The 1⁄2″ and 3⁄8″ stops from my Fuller pilot bits fit but they block the exit for the wood shavings.

This type of countersink is also well-suited for metalworking. Holes drilled in metal often have sharp burrs around the edges. I’ve been filing them off, but while that makes the holes safer to handle, the marks left by the file don’t improve their appearance. The countersinks, on the other hand, cut a clean, shiny bevel. The deburring function works just as well on holes drilled through wood.

I kept my set of zero-flute countersinks handy while I was building a new boat cart for one of my canoes and used them to dress up every hole I drilled. They have worked beautifully in fir, mahogany, oak, ipe, and aluminum and are a pleasure to use. ![]()

Christopher Cunningham is the editor of Small Boats.

The Countersink Set by KEO Cutters cost $86.67.

Is there a product that might be useful for boatbuilding, cruising, or shore-side camping that you’d like us to review? Please email your suggestions.

Chris,

I came upon this type of countersink quite by accident. It looked cool and as all my other countersinks produced consistently awful results it seemed worth a try. Well, I agree with you wholeheartedly. It is a little miracle, a true work of genius!

Andrew

Can they be sharpened?