I picked up a Morris today at an estate sale…” writes an enthusiastic Wooden Canoe Heritage Association (WCHA) Forum user. Photos of a wood-and-canvas canoe with sweeping lines illustrate his entry.

“Nice find!” responds a voice from New York.”

“Thou shalt not covet thy neighbor’s stuff, but I’m going to anyway. Seriously nice boat,” rings another.

The posts roll on. “They are great boats!” And finally, “Can’t wait to see it on the water.”

Who was B.N. Morris, and why do his canoes inspire such reverence?

Around the mid-1880s, B.N. (Bert) Morris set up his wood-and-canvas canoe shop on the banks of the Penobscot River in Veazie, Maine. A few miles south in Bangor, a decade earlier, Evan Gerrish had become the first commercial builder of this type of canoe in Maine—and perhaps the world. E.M. White followed Morris. All three companies predated the arrival of the Indian Old Town Canoe Company, founded around the turn of the 20th century.

The early wood-and-canvas canoes were direct descendants of the Penobscot birchbark canoes and, as with their predecessors, their design was pure utility; these were workboats used by guides and lumbermen. While the bark canoe is built on the ground starting with the bark skin hull and rails, the wood-and-canvas boat uses a form (somewhat like a cobbler’s last) and begins with the ribs and rails—uniform larger-scale production being one of the goals of the method. At the time, forms, also known as building jigs, were used to build peapods and skiffs in Bangor, but Gerrish was the first to link the form with the wood-and-canvas canoe. Earlier, all-wood canoes were being constructed in Peterborough, Ontario, and Canton, New York, utilizing forms, but Maine builders are believed to have devised their method independently.

Rollin Thurlow has been building wood-and-canvas canoes since the mid-1980s. He has taken measurements from and drawn lines for this 17′ canoe, a classic that Bert Morris designed early in the last century.

Bert Morris was the first Maine canoe-builder to adapt his design for the growing recreational market. As the company departed from the sleek native design (narrow beam, sharp entry), his boats became wider, fuller, and more stable. They acquired the elegant upturned sheer that would become Morris’s signature. Each detail led to a boat of uncompromised quality: Straight-grained, quarter-sawn planks were nailed snugly together (done to minimize swelling and to maximize strength), each with the appropriate number of tacks in a staggered pattern so not to crack the 3⁄8″-thick ribs. Rib grain was chosen for strength as well as aesthetic fluidity, and each rib (of the closed gunwale design) was cleanly tapered to fit into its mating inwale mortise. Rail grain was matched; decks fit tightly…the list goes on.

Sadly, in 1920 a fire destroyed Morris’s enterprise. At the time, he had 75 employees and was one of the largest and most respected canoe manufacturers worldwide. After the fire and for the last decades of his life, Bert returned to his roots and operated a one-man shop from his home.

After World War II, aluminum canoes chipped away at the wood-and-canvas canoe’s popularity, and by the mid-1960s fiberglass ruled the market. However, in the mid-1980s, a few impassioned builders led a wood-and-canvas revival. Among them was canoe-builder Rollin Thurlow. He chose the Morris 17′ Model A as one of the designs to help lead the charge.

Rollin carefully fits a deck piece around a steam-bent coaming. The coaming will be let gently into the inwales. Although closed (capped) wales were the norm very close to the time of this canoe’s debut in 1910, this model has open wales that enable better drainage.

Bearded, jovial, and quick with a laugh, Rollin is a humble grandfather to the wood-and-canvas canoe movement. Thurlow and his longtime friend, canoe-builder Jerry Stelmok, wrote The Wood & Canvas Canoe in 1987, a historical and how-to text now a mainstay in the libraries of most who have since plied the trade.

Rollin remembers fondly when (in his basement) he built the form for the Morris 17′ Model A—having taken the lines from a boat of 1910 vintage. For him, Morris came to symbolize the height of that romantic era in wood-and-canvas design. If the evolution of the canoe, hundreds of years in the making, were a hot fudge sundae, then Morris would be the shiny cherry perched atop that sweet bed of human ingenuity.

To paddle a Morris is to connect with living history. I had that opportunity on a backwoods pond a few minutes from Rollin’s shop. Several quick strokes brought the Morris up to speed. The breeze in my hair and an emerald wake put a smile on my face. The Morris holds its line with gusto, courtesy of its slight rocker (1⁄2″) and external keel (standard issue—7⁄8″ wide, tapering to 3⁄8″). The Morris has a relatively full entry that causes the bow to ride over the waves rather than crash through them.

On that blue-sky day, I planted my knees against the ribs and rocked the hull to and fro as I glided over the quiet pond. The shallow arch of the hull (a compressed U-shape in section) gives the Morris stability without sacrificing comfort—it is an appropriate design for the average canoeist. I found it easy to pull a smooth vertical forward stroke along the edge of the gunwale, thanks, in part, to the 10 degrees of tumblehome. Open gunwales allow the boat, on land, to drain when rolled up on its side (before 1910, closed gunwales were the norm).

A traditional wood-and-canvas canoe is built on a sturdy form intended for mass-producing a single design. Here, ribs have been steam-bent over steel straps that wrap around the form—and planking has begun. Planks are fastened with small, solid brass canoe tacks that are driven through the planking and ribs, contacting the steel strapping below. This contact causes them to curl around and hook back into the rib from the inside, holding the plank fast to the rib.

The Model A was intended for general use. Its 17’1″ length overall allows for a nice blend of speed and legroom. Its 12″ depth provides some carrying capacity and enough freeboard to keep the waves at bay. The 33″ beam strikes a reasonable balance between performance and stability. At 85 lbs (dry weight), the Model A can be portaged by a single (albeit strong and determined) individual.

As I paddled, my eyes kept returning to the texture and shine of the hull’s cedar interior. The glow of the mahogany trim (rails, decks, thwarts, seats, and floor rack) and the long deck with its brass flag socket— dating back to canoe club days—give the Morris a regal finish (mahogany trim, exterior oak stem band, and long deck signify the Morris company’s Type Three finish).

A rather unique Morris detail is the cedar stem that splays (spreads) to 3″ at the heel. Stems of ash (7⁄8″ square) were the routine on other brands of canoes. It’s not completely clear why Morris deviated—perhaps because cedar is more rot-resistant than ash but, being softer, requires more girth.

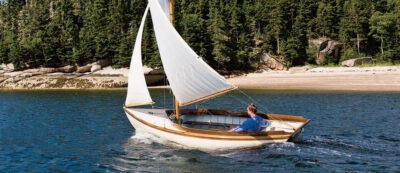

Poling is a popular pastime among canoe enthusiasts.The Morris’s weight combined with her relatively flat bottom gives her good initial stability.This makes her an excellent choice for poling or for general use in calm waters.

This and the other details of a Morris canoe equate to a boat with lasting synergy. Subtleties such as plank fitting, matching grain, the shaping of trim, deck coaming, and copper seat spacers are independently easy to miss, but collectively they add up to the unique style of a Morris.

“The canvas can hide a lot of things,” said Rollin. “But Morris canoes are always good wood underneath— the quality, the shape, the fits were all excellent. Morris was paying attention.”

This attention to craftsmanship has found a kindred spirit in Rollin.

Peter Wallace, Rollin’s business partner and shop mate, poled around the pond in the Morris, his smiling yellow Lab keeping watch up forward. Peter reminded me of one of those starry-eyed sternmen floating the Charles River in Morris’s heyday. I imagined an onboard Victrola radiating love songs, enough cushions to keep the courtship cozy, and the canoe club pennant coursing in the breeze. Like those jubilant folks on the WCHA Forum, I too was entranced by a desire to capture a moment from another time; a time long ago and far away.

Rollin and I took one final spin. “A big part of a wooden canoe is just the appearance of it, the curves that a boat takes, the romance of it,” he said and then mentioned how wood tantalized his senses—the look, feel, and smell. “Maybe human development hasn’t progressed out of the woods that much, maybe we’re still attracted to wood that way.”

The upturned sheer (a signature of the Morris canoe) and long, sweeping decks are but a few of the elegant features that set this design apart from many other wood-and-canvas canoe designs. Construction drawings show information in quarters, rather than in halves, due to the canoe’s symmetrical ends. Body plan views show possibilities for two construction methods: stripping and traditional wood-and-canvas.

This Boat Profile was published in Small Boats 2010 — plans are available from The WoodenBoat Store.

I am not sure how you maintain your paddling position, or transfer any power to the water when kneeling behind the centre thwart as pictured here. Standard practice with the symmetrical Chestnut and Peterborough canoes that I grew up with here in Canada, would be to paddle it “backwards” in a kneeling position with the thwart aft of the front seat to support your bum. With most designs this places the centre of gravity just aft of the centre of the boat (from the paddler’s perspective) , producing a slightly bow-up trim that still gives you good control.

Rollin Thurlow is supporting his bum on a kneeling thwart located more or less the same distance from the stern that the position you describe from the stem (actually the “new” stern of this double-ender).

This big canoe once fitted with oar locks would row marvelously…