We were looking for a stable platform for fishing our local southern California waters with ample range to motor across the border to try our luck in Mexican waters. We also wanted to share our father-and-son adventures with others, so we needed a boat with the capacity to accommodate up to four fishermen.

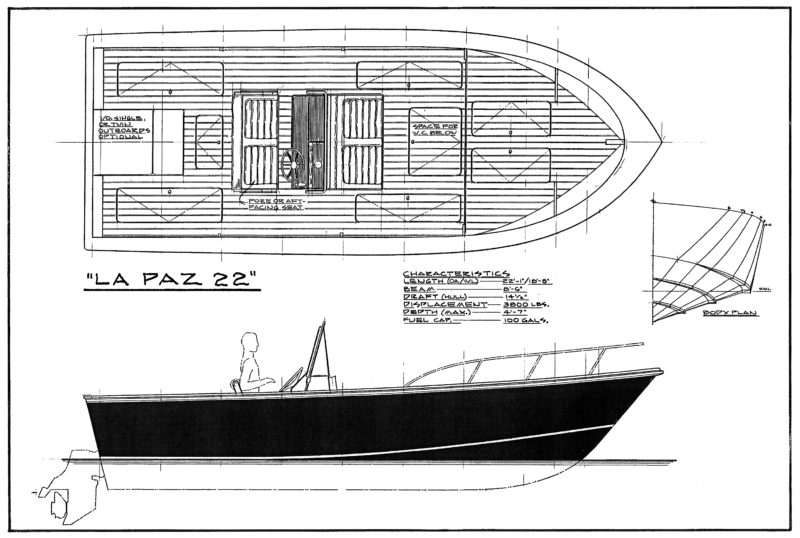

Our web search of designs led us to the Glen-L La Paz 22. We were drawn to its spacious self-bailing open cockpit, seaworthy deep-V hull, and the range its 100-gallon fuel capacity would provide. The La Paz was designed as a trailerable center-console sportfisherman by Ken Hankinson—Glen L. Witt’s friend and partner at Glen-L.

The plans give options for building in either aluminum or plywood as well as changing the station spacing to build a 20′ or a 24′ version. We chose plywood, as we both (dad Mark, son Ryan) have a background in woodworking, epoxy, and fiberglass. And some 30 years ago Mark had built a Glen-L Hunky Dory.

We purchased study plans, decided to go forward with the project, and then purchased the plans and full-sized patterns for plywood construction along with Witt’s book Boatbuilding with Plywood. The plans give a wealth of information about the construction schedule, frame layout, and all the key elements of the build. Paying close attention to the detailed plans and patterns, especially before we cut any materials, saved us time and money.

Photographs by Dennis Eaton

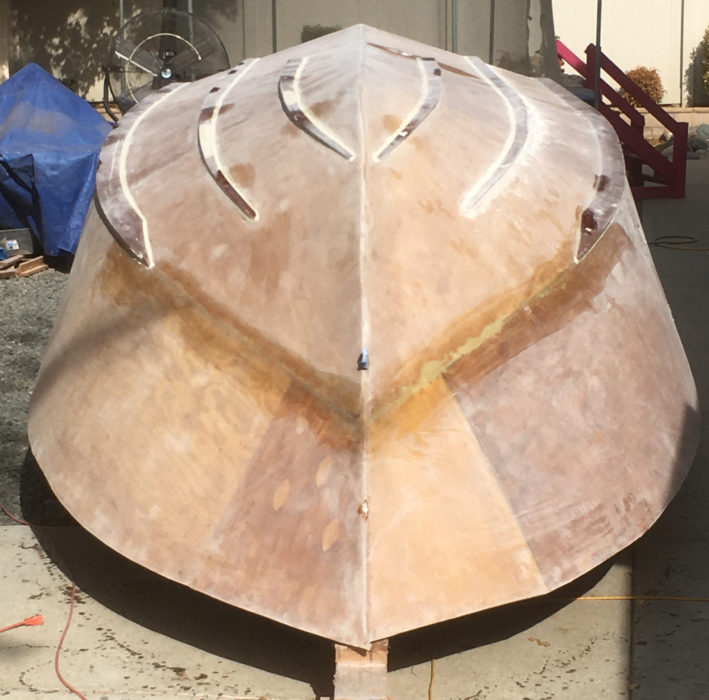

Photographs by Dennis Eaton The chine flats and lifting strakes are applied to the outside of the ‘glassed plywood hull and are meant to provide lift and reduce friction.

No lofting is required, so the La Paz construction—in any of the three lengths described in the plans—starts with building the seven frames, the transom, stem, and breasthook. The full-sized, half patterns for the frames and transom are transferred with carbon paper to a 4′x8′ sheet of cheap plywood that will serve as a table for assembling the frame and transom parts. Each frame consists of four individual pieces of solid wood gusseted together with 3/8″ marine-grade plywood and epoxy. The plans recommend vertical-grain Douglas-fir, Alaskan cedar, Southern pine, and Philippine, Honduras, and African mahogany. We made the frames with sapele; the plans give options for either 4/4 or 5/4 stock, and we chose 4/4 due to its availability.

The transom is drawn with options for configurations to suit a single outboard, twin outboards, or an inboard/outboard. It is made of two laminations of 3/4″ plywood with mahogany frame members. We added an additional lamination of 3/8″ plywood for extra strength and rigidity.

There are full-sized patterns for the stem and breasthook. The stem is made of three layers of 3/4″ marine-grade plywood; the breasthook has two layers.

The frames, transom, stem, and breasthook are all secured on a building jig made of 2×6 timbers anchored firmly, square, and level to the shop floor or ground. The frames are set square across the jig’s centerline and anchored to it with cross spalls secured to the frames at the design waterline (DWL). The keel, bottom battens, chine logs, and sheer clamps are bent in place without steaming, then secured with epoxy and bronze screws. The longitudinals are fastened with silicon-bronze screws and epoxied in place. The chine log, sheer clamp, and bottom battens are all beveled to provide a fair, flat mating surface for plywood planking. We used a grinder with coarse 80-grit paper to remove the bulk of the material, then finished with a block plane.

The plans include options for powering the La Paz with an inboard/outboard, twin outboards, or, as shown here, a single outboard. The actuators of the trim tabs that were added are visible here.

The plans do not include templates for planking, and Boatbuilding with Plywood recommends bending oversized plywood panels around the frame and tracing their outlines. We chose to first make cardboard templates to minimize waste. The 3/8″ side planking goes on first. Plans note the options for scarfing 8′ sheets to make full-length panels to apply in one operation or using butt joints to fasten the 8′ lengths of plywood one after another one the building form, joining them with butt joints. The butt joints are backed with 3/8″ plywood plates that span between chine log and sheer clamp and get epoxied and screwed in place. We opted for the latter for ease of installation.

Once the side planks are in place and their edges beveled flush with the chine logs, the bottom planking is installed, with sections butt joined. The aft section can be planked with 1/2″ plywood; the forward section is laminated with two 1/4″ sheets of plywood in order to accommodate the bend and twist in the bow area. Wet towels applied and left overnight made the plywood easier to bend.

While the plans call for sheathing the hull with one layer of 7.5-oz fiberglass cloth, we chose to use two layers for added durability. All corners and joints have doubled layers of fiberglass cloth. After the ’glassing process and final sanding, chine flats and lift strakes are installed and ’glassed in place. Once faired, the boat is ready for paint.The plans give dimensions for cockpit layout with center console, hatches, and an elevated casting deck forward, but this was one area where we deviated from the plans. We extended the fore anchor locker, and built an insulated fishhold under the raised casting platform. We also chose to foam-fill the entire hull under the sole for noise dampening? and safety, built a taller center console than plans detail with a centered helm, and purchased a leaning-post that provides a higher vantage point and, unlike a seat, lets the skipper’s legs absorb some of the shock when powering through chop. Like the designed console, ours has a seat built into its forward end, hinged to provide access to storage space. Our dual batteries and wiring panel are housed inside the console.

We purchased a T-top for some relief from the Southern California sun. It’s equipped with rod holders to supplement those attached to the seat and recessed in the side decks.

The La Paz was designed with a center console that could accommodate two on the helm side and two forward. The T-top was installed by the builder over his modified console to provide relief from southern California sunshine.

The cockpit sole is elevated above the waterline and self-drains aft through fittings in the transom. The 100-gallon fuel tank, made of aluminum by a metal fabricator, sits between frames under the sole and console. It keeps the weight amidships so the hull is nimble in rough water and trims properly whether the tank is full or empty.

The La Paz’s 8′6″ beam, lift strakes, and chine flats ensure a stable ride with superb handling. In moderate conditions the ride is dry if the wind isn’t picking up the spray and sending it on board. We installed electric trim tabs to keep the bow down in adverse conditions. The boat handles 3′ to 4′ seas well; the full-length deep-V hull softens pounding, but add wind and you’ll be slowing down to stay dry.

With a 135-hp outboard at wide-open throttle, the La Paz can hit 35 mph. It can accommodate an even more powerful motor. The 100-gallon fuel tank built into the hull under the console provides a respectable cruising range.

We powered the boat with a Honda BF135, which quickly gets it on plane and to a top speed of 35 miles per hour. If we were to do it again, power would be upgraded to 150 horsepower. Glen-L notes estimated speeds for motors ranging from 80 to 225 BHP (brake horsepower, measured at the motor without the losses created by a drive train), noting “the higher figure should not necessarily be considered the maximum rating.” The fuel consumption is economical, averaging around 3 to 4 miles per gallon. Given the 100-gallon fuel capacity, we have more than ample range for southern California fishing.

Our 24′ La Paz sits on a trailer we had custom-made. It weighs roughly 4,000 lbs fully loaded and trailers like a dream. At the launch ramp it can be handled by one person, but usually needs to be walked off and on with the trailer close to the dock. Two pairs of hands are best for a quick launch.

The La Paz has been a wonderful boat, and we are looking forward to many years of good times on it. It has fulfilled our expectations for a safe, stable, and economical center-console sportfisherman. We would highly recommend this design to anyone who has the time, space, and motivation to embark on such a boatbuilding project. Building it took us the better part of 18 months and was no easy feat to complete; there were times during the build that both of us doubted our ability to finish this project, but with a little fortitude and persistence, things fell into place. All in all, it has been the most rewarding project that either of us has worked on to date. The boat, with its classic lines, draws attention from most all who see it since it is definitely not your typical production center-console. While offshore fishing is our main objective for this boat, it will be just as at home on any smaller body of water. ![]()

Mark McDaniel is a recently retired airline pilot, and his son Ryan is a first-year middle-school teacher. They both have an affinity for all things saltwater and have long enjoyed woodworking.

La Paz 22 Particulars

[table]

Length/22′1” with options for 20′ and 24′

Waterline length/18′8″

Beam/8′6″

Hull draft/1′3”

Hull depth, maximum/4′7″

Displacement/3,800 lbs

Fuel capacity/100 gallons

[/table]

Plans for the plywood La Paz 22 are available from Glen-L for $284. Study plans cost $15.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us!

Nice build! How has it been fishing? I have been thinking about taking my dory down the east side of Baja camping out and fishing.

After some use – anything you would do differently?