Bryn Morgan has spent all his working life at sea, but until now he had never had a boat of his own. For many years he had his eye on an 18′ Plymouth Pilot, a fiberglass production boat with lines based on a 1930s pilot vessel that operated out of Teignmouth in Devon, on the south coast of England. But when his son-in-law, Adrian St. Aubyn, a Venezuelan with Cornish ancestry, enrolled at the Lyme Regis Boat Building Academy in 2015, he realized there might be a better opportunity.

Six years earlier, another student at the Academy, Alasdair Grant, had built STEADFAST, a 16′5″ version of a 15′3″ Beer Beach boat called WILD DUCK. Beer is a village located in the middle of the Lyme Bay coast, and the boats built there had evolved over many years and came in various shapes and sizes, all seaworthy enough to cope with the exposed coastline of south Devon and durable enough to be hauled up the steep, heavily pebbled beach there. WILD DUCK was built in 1963 for crabbing and bareboat charter, and she was still on Beer Beach when Alasdair and his classmates took the lines off her.

When Bryn saw photographs of STEADFAST, he fell in love with her and started talking to Adrian about building something similar while he was at the Academy. Bryn wanted something bigger than WILD DUCK, around 21′ but the administrators were concerned that would be too big to complete in the time available. They settled on 19′ with a raised foredeck and wheelhouse, agreeing that STEADFAST’s lines were a perfect starting point.

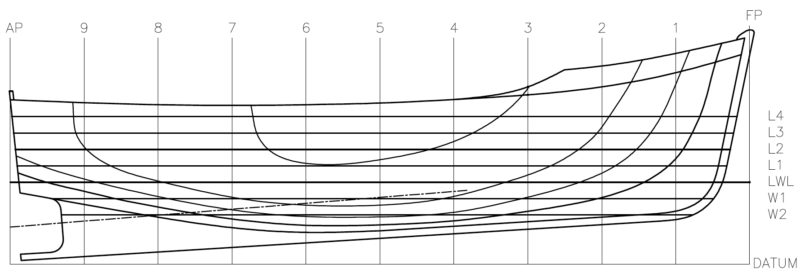

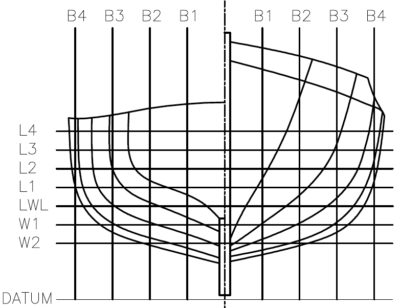

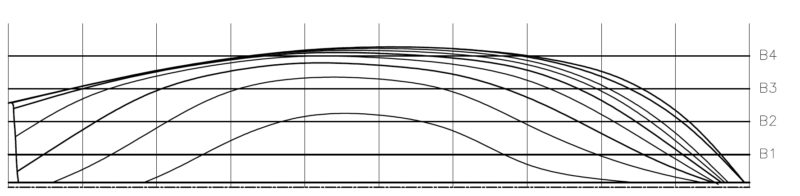

Adrian took STEADFAST’s table of offsets, put it into AutoCAD, and scaled it up to the desired 19′ with all other dimensions increased proportionally. He then faired the lines on a full-sized lofting and adjusted the offsets.

photographs by the author

photographs by the authorBuilder Adrian St. Aubyn perched on the engine mounts to enjoy his handiwork.

Construction began with an all-oak backbone. The stem was laminated from 18 pieces of 5/32” veneer; the 5-1/2″ x 2” hog and 2-3/4″ square keel were both laminated from two pieces; and the deadwood, made up of 14 pieces, incorporated a swelling through which the stern tube would be bored. An extension from the deadwood’s lower edge provided an attachment point for the bottom rudder pintle. All the pieces were joined with epoxy and copper and bronze fastenings.

Adrian cut rabbets in the hog and keel for the garboard, and in the stem for the hood ends of all the planks. The whole assembly was then erected on a temporary structure about 2′ off the workshop floor, and the top of the stem was secured to an overhead beam.

The 2-1/4″ stern knee and 1-1/4″ oak transom were then fitted, and then the nine temporary molds were set up at their stations and secured to the overhead beam. Sixteen ribbands were laid along the length of the boat so that the position of the top edge of each plank could be determined and then marked on the molds, transom, and stem. When the ribbands were removed, it was time to fit the 3/4” larch lapstrake planking.

The builder, left, and owner Bryn Morgan make themselves comfortable in the sternsheets. The throttle used while steering with the tiller is just below Bryn’s left hand.

The garboard plank—8″ wide at its widest point—was taken a little further up the stem than initially lined with the ribbands to induce more taper and lift to the forward ends of the other planks for a more pleasing profile. As soon as this was fitted, the gains, known locally as geralds, were cut at each end of the top of the garboard to allow the next plank to finish flush with the outer part of the stem and transom.

From there the remaining 14 strakes were fitted. They all had to be steamed at their ends to cope with the twist, and most had a scarf joint in them. In each case, the lands were bedded with an oil-based mastic and then fastened with copper clench nails while the ends were epoxied and screwed to the stem and transom.

The 1-1/4″ x 5/8″ oak frames were then steamed and fit between the molds on 6” centers. Almost all of these were continuous from sheer to sheer, but the forward-most five were fitted in separate halves on each side. The molds were then removed after two braces were temporarily laid across the hull to retain its shape, and the remaining frames were fitted. The sheer forward was then extended upward for the raised foredeck by fitting an extra plank flush with the sheerstrake and supported by an extra 10 short frames.

The motor housing conceals a 14-hp two-cylinder Yanmar diesel.

Adrian fit the internal structure: the 4-5/8″ x 1” oak beam shelf, the 3-3/4″ x 7/8″ larch bilge stringer, the 1-1/2″ x 1-1/8″ oak risers (the aft parts of which would support the side seats), and five 1-3/8″-thick laminated oak floors. Two sawn frames, 1″ thick and averaging 3″ deep, are joggled with limbers above every lap and doubled up from about the riser downward to stiffen up the open part of the boat. The 3-1/2″-thick engine beds span the sawn frames.

After the 1-1/2″ x 2″ oak deckbeams were fitted forward and aft, an oak laid deck with no plywood subdeck was fitted over them. The oak railcap, running the length of the boat between the decks, is 4-5/8″ x 1″. The wheelhouse is made up of 1 ¾”-thick solid sapele sides and front, with 1-7/8″ x 1-5/8″ roof beams, covered by 3/4″ ply and a layer of ’glass and epoxy.

The four 3″-square mooring posts were made of reclaimed wood that had been Falmouth docks. They were the only pieces of wood on the boat for which no money changed hands, but Adrian described them as “priceless, because they belong to this place,” referring to ELLY ROSE’s home port. That was where Bryn, Adrian, and I met up for a sea trial on ELLY ROSE on a blustery winter’s day.

Cruising speed with the 14-hp diesel is around 5.5 knots.

With Adrian at the helm, we maneuvered our way out of a tricky berth and then motored down the Penryn River. The Yanmar 14-hp two-cylinder diesel gave us 5.2 knots at the cruising rpm of 2,500, and 5.6 knots at 3,000, but the Force 6 headwind was clearly having a significant effect on the sizable wheelhouse. So we turned around and found that going downwind, she went a little faster: 5.4 knots and 5.9 knots at the respective rpm. Not surprisingly, her turning circle was also affected by the conditions. While it was about three boat-lengths (at 2,500 rpm) turning into the wind, it was little more than half that turning away from it.

Bryn and Adrian told me that they had decided to fit the engine in the deepest part of the boat without calculating the effect on the center of gravity. When the boat was launched, they found that she was bow-down and difficult to steer, especially when in reverse. The prop was too close to the surface and not really biting properly. They put around 575 lbs of lead ballast aft, which seems to have done the trick—I found her easy to steer in both directions. They have in mind moving the engine aft at some point in the future.

The rudder can be operated at the tiller or by a wheel in the pilothouse. A hydraulic piston mounted under the aft deck is connected to a bolt through the rudder stock that extends through a slot high on the transom.

There are two steering positions: a wheel in the wheelhouse (especially welcome on that very cold day!) and a tiller aft. Both have gear and throttle controls, and it is a simple matter to make sure one is in neutral before assuming command at the other station. A valve in the aft locker disconnects the hydraulic wheel steering to allow the tiller to be used. I am 6’ tall and, although I could stand in the wheelhouse, I had to stoop a little to get a clear view forward. I also had to stoop at the tiller to get a view through the wheelhouse windows. Bryn is 5′8″ and has no trouble in that respect, and neither of us did when sitting on the engine box forward or on the seats adjacent to the tiller.

Bryn and Adrian had been farther out to sea than we went that day, and Bryn said he was delighted with ELLY ROSE’s seakeeping qualities, especially when punching her way through the waves in a more exposed stretch of water.

Bryn is very much looking forward to using ELLY ROSE during his impending retirement. He plans to use her for fishing, hauling crab pots, picnicking, and visiting secluded beaches accessible only by boat. She will, I am sure, be perfect in all those roles.![]()

Nigel Sharp is a lifelong sailor and a freelance marine writer and photographer. He spent 35 years in managerial roles in the boat building and repair industry and has logged thousands of miles in boats big and small, from dinghies to schooners.

Beer Beach Boat Particulars

Length: 19′

Beam: 7′ 3 1⁄2″

Waterline length: 18′

Draft: 25 1⁄2″

Adrian St. Aubyn

Adrian St. Aubyn.

For lines and a table of offsets, email Mike Broome at the Boat Building Academy.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Monthly readers would enjoy? Please email us!

I am smitten. What lovely things adorn the waters, and this is one of them for certain…wow, just wow!

Oh boy, that would be a fun project – no stitch and glue on that baby. I can see me in that little wheelhouse with a cuppa joe out trolling Buzzards Bay, line off stern waiting for a striper hit.

Cracker

Sweet!