If you are born with the name “Seaman,” your career path is almost preordained. Somewhere in the past, by definition, there are wooden boats in the bloodline. Dave Seaman may have come by the inclination to build boats naturally, but the lines and construction of his latest boat, ZEEK, are the product of study and experience. ZEEK is a 21′ LOA Alaska Sea skiff specifically designed and built for the short chop and steep gravel beaches of Alaska’s Kachemak Bay.

The south side of Kachemak Bay is a roadless area of snow-covered peaks where the only transportation is by boat. It has some of the largest tides in the world, and the rips and currents are a challenge. The early settlers there used dory-like rowing boats, with lots of rocker and flare—boats designed to survive in tough conditions. As engines replaced oars, transoms got wider and planing boats became the norm, but many of the design characteristics remained the same.

During the first years of his boatbuilding career, some 30 years ago, Seaman was part of a small group of self-reliant men and women who lived in those same remote coves and harbors. Builders like Seaman, Dick Dunn, Jim Landis, and George Hamm built the boats that people needed to travel year-round in the Bay’s sometimes harsh weather. They collaborated on designs, learning from each other’s boats and figuring out the details that make boats fit a particular combination of sea and shore. Materials often came from the Sitka spruce that covers the slopes or the cedar logs that would wash up on the beaches, flotsam from Japan-bound log barges. Logs were cooperatively cut on a one-man mill and sorted into two piles—construction lumber and boat boards.

South Bay celebrations sometimes had a dozen elegant home-built boats pulled up on the beach or rafted out on a running line. Like New England and Puget Sound, Kachemak Bay became a focal point for wooden boats. That heritage survives in the annual Kachemak Bay Wooden Boat Festival, which takes place in the small town of Homer each September.

Will Rice

Will RiceZEEK’s V-hull cuts through the chop, while her flaring bow and ample freeboard make her a dry boat.

One of Seaman’s earliest boats was built from a set of Pete Culler plans, and Culler’s influence has continued throughout Seaman’s career. Culler summarized his own design philosophy by saying, “To be successful at sea, we must keep things simple.” Capt. Culler’s philosophy shows in the clean lines and uncluttered structure of ZEEK.

Seaman’s construction details have been developed by years of fixing boats that he had built, restoration jobs on old boats built by old-timers, and keeping up a traditionally built, wooden, commercial fish boat. Fishing is a business where you learn the hard way about what breaks and what works. Fishing boats are built to take a beating, and Seaman incorporated the best of those design strengths into his own boats.

The addition of stitch-and-glue construction into the toolbox, along with customers who have believed in the process, has allowed Seaman to experiment, and usually that ends up back at simple. The hull shape, light weight, lack of appendages, below-decks engineering, and ease in cleanup make for user-friendly service for the long term. This design makes highly efficient use of wood fiber, still recognized as the most resilient of boatbuilding materials.

Kachemak Bay opens onto Cook Inlet, not the hard waters of the North Pacific. Consequently, it rarely produces big seas during the summer season, but the afternoon day breeze means that a 3′ chop is a standard operating condition. Given the temperature of the water, a wet boat is a serious design flaw. Seaman, who now lives in Homer, understands the importance of bad-weather handling. Twice a week, year round, he uses his 24′ boat to deliver the mail to places on the other side of the bay. It gives new meaning to the phrase “through rain and sleet….”

Seaman has built 25 boats, all of them designed for Kachemak Bay. ZEEK is a product of that evolution. Seaman collaborated with the boat’s owner, Kirk Vasey, in the design and construction of boat. Intended as a recreational runabout, she would also be suitable for various other operations, such as a water taxi for carrying up to six passengers.

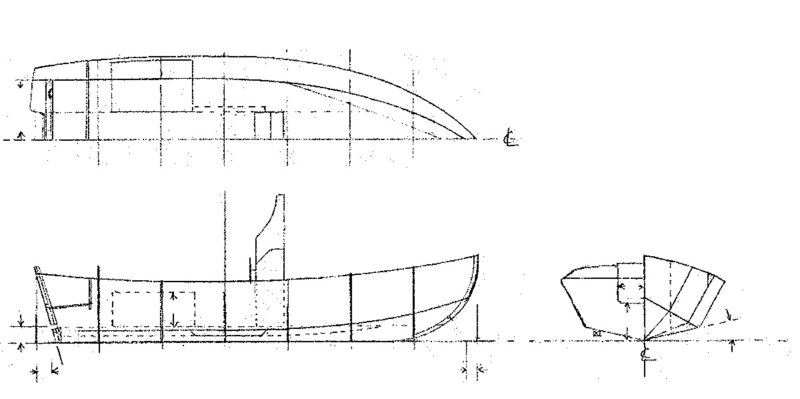

Once he had the design parameters in mind, Seaman drew the lines on grid paper and generated a table of offsets. He then lofted and corrected the offsets. Patterns and molds were made from the lofting. Six molds were used, plus a stem pattern and a transom pattern. ZEEK is built with a low deadrise—13 degrees from ’midships aft and 25 degrees from the bow for about a quarter of the boat’s length. With a hard chine, a lot of freeboard, and significant flare in the sides, she is a dry boat. There are no skegs or other projections to interfere with the flow of water under the hull, so she is fuel-efficient.

Will Rice

Will RiceThe Alaska Sea Skiff can be built with a center console or a deckhouse.

ZEEK gets her strength from a monocoque design, in which the structural load is carried by the outer skin, much like a modern jetliner. The floor and bottom form a rigid triangle, the most stable geometric shape. She has no cross bulkheads, but instead relies on three longitudinal stringers under the floor. Two stringers run about halfway between the keel and each chine. The third runs down the center and provides direct support for the keel. The stringer configuration helps equalize the stresses and stiffens the hull with additional triangular shapes. The floor sits above the design waterline and, with a pair of 4″ scuppers, it is self-bailing.

The stringers, the hull, and the floor are tied together with double layers of ’glass cloth, providing rigidity fore-and-aft. The construction provides enough torsional give to dissipate the energy that a planing boat absorbs when it is pounding in rough water. The design avoids the popped bulkhead seams that are one of the most common repair problems in the Bay. Seaman says the concept is similar to the natural knees used for framing on the old wooden fishing boats. The roots used for those knees were flexible and resulted in a boat that could take years of heavy use with only minimal repair issues.

Construction is stitch-and-glue, with 1/2″ and 3⁄8″ marine fir plywood. Three sheets of plywood were scarfed together and steam-bent into shape. Every plywood surface inside and out is covered with a layer of 6- or 10-oz ’glass cloth and epoxy. The inwales are open and constructed from single pieces of wood, without scarfs. The rails are an integral design element in an open boat without obstructions for walking about. The inside rail is ironbark—a heavy, dense eucalyptus. The outside rail is fir. The open design means that cleats are not necessary, and the single-strip construction adds strength and rigidity to the hull.

With the huge tides that are the norm in Kachemak Bay, few places have docks (boats are typically kept on a mooring or a running line). Landings at the remote cabins that dot the bay are typically on a gravel beach. During the winter, ice is an issue. Needless to say, the bottoms of boats here take a beating. To protect ZEEK’s hull and provide the necessary strength, everything under the floor, and the bottom of the hull, inside and out, is covered with a double layer of cloth and epoxy. The center stringer provides strength to the keel. A strip of “Keelguard,” a polymer, self-adhering composite, provides additional protection. A bow deck facilitates loading and unloading onto a beach.

The boat carries two 20-gallon fuel tanks, which provide plenty of range. These in-seat tanks have waterproof covers. Wires and hoses are located under the deck in waterproof chases. GPS, VHS, and depth-sounder have waterproof switches and breaker panel. Kobelt hydraulic steering controls the Honda 90-hp four-stroke outboard. ZEEK has a stand-up console, but a sister boat with identical lines is fitted with a house. Seaman said, “All boat designs are a compromise, but there was no compromise on the materials or systems.”

With a displacement of only 1,200 lbs—1,700 with a 90-hp Honda outboard—she can be a bit tender, but fast and comfortable in the typical chop. However, she is also quick and maneuverable, and Kirk Vasey, the owner, reports that in 10′ rollers the combination of light weight and lots of power means that she is easy to steer through the troughs. And in flat conditions, she will jump up on plane and do 30 knots. Her light weight means that she can be towed on a single-axle trailer.

Seaman has built three boats from the design and molds. The construction took Seaman and Kirk about 15 months.

Seaman said that his goal was to build a boat that was faster, prettier, stronger, and lighter than the competition. ZEEK appears to meet those standards. ![]()

Will Rice is a widely published Alaska writer and the author of Fly Fishing Secrets of Alaska’s Best Guides, and co-author of Fly Fisher’s Guide to Alaska.

For Zeek plans and information about other designs from Dave Seaman, email him at [email protected].

Alaska Sea Skiff Particulars: LOA 21′, Beam 8′, Displacement 1700 lbs, Power 90 hp, Maximum speed 30 knots

Any possibility of getting plans for this boat? Thanks.

Yes, I have a package prepared with a plan, instruction, and many photos. Send me $50 and I will email it to you.

Dave

Dave Seaman

PO Box RDO

Homer AK 99603-8999

This is a “Great Looking” boat!

This is exactly the type of boat design I have been looking for to build.

Although Seaman boats is no longer in business….

Is there anyway to get a set of plans for building this boat??

Thanks

Me too! I want plans! Article says there’s plans!

Watch this space…