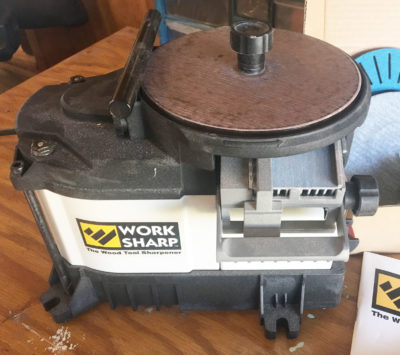

The air-cooled tool guide angles upward underneath the wheel. The top face of the wheel can be used, with the help of the tool support at left, for large or curved blades. In the box at right there is a slotted disk that provides a view of the blade being sharpened on the tool guide. Photo and video by the author

Photo and video by the author

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.

I bought a WS-3000 about 5 years ago and I haven’t worked with a dull chisel or plane since. Just a matter of seconds to touch up a blade. It may be possible to get a sharper, more reflective surface on a chisel or plane blade, but not with my skill set or my level of patience. One of the best buys I’ve ever made.

This unit is going on my letter to Santa…