photographs by the author

photographs by the authorThe author was equipped to spray the truck-bed liner, but while that produced the desired results, she decided that rolling the coating on would be quicker and less expensive.

The first time I saw truck-bed liner paint as the interior finish of a pulling boat was while reviewing Sam Devlin’s Duckling for Small Boats Monthly. Thick for durability and textured for traction, it immediately made sense to me. I grilled Sam about where to find the thick coating, how to apply it, how long it lasts, and if there were any fading or chalking issues with the product he used. I row year-round in the San Juan and Gulf islands, where long hours of exposure to the summer sun and gravelly and sandy beaches mean my boats get hard, grinding use. The bed liner won’t stop an errant sharp knife point from puncturing it, but it will handle anchors and anchor chain, the bottoms of coolers transferred from a sandy beach, and gravel stuck on the bottom of rubber boots. Sam has even used truck-bed liner on the exterior of some small boats where a durable finish is more important than a perfectly flat one.

Black is the longtime standard color for truck-bed liner paints, but too dark for my taste and too hot in the summer sun, so I surfed the web looking for a do-it-yourself tintable bed liner. Some manufacturers—Duplicolor, Plasticoat—make water-based bed liners that may be easier to work with, but my research suggested they produced poor results. I went with Monstaliner, a tintable aliphatic hybrid urethane polymer that can be rolled or sprayed, and ordered a couple of free paint chips from among the 39 colors available.

I chose a light slate gray color that will, combined with the pebbly texture, reduce most of the glare I used to get from the previously high-gloss surfaces in my rowing dory, MAC. It is also guaranteed to have 100 percent UV permanent color for a minimum of five years. The online application instructions are detailed and complete. Monstaliner comes in a kit that includes textured rollers, masking tape, abrasive pads, and more—just about everything you need to do the job—but I already had all of the prep materials and was equipped to spray it on, and so just bought the “coating only” kit with the coating, tint, catalyst, stirring stick and mixing paddle for an electric drill.

Proper surface preparation and careful taping are a universal requirement for applying any coating. The supplied instructions reminded me that the time spent on application is only a fraction of the time prepping and cleaning up. After taping gunwales and those surfaces I didn’t want to spray, I scuffed the remaining painted interior surfaces with Scotchbrite pads and vacuumed up the fine dust, followed by a wipe-down with a rag and MEK (methyl-ethyl-ketone). Bed liners have a high VOC rating so I suited up with goggles and a respirator and got lots of ventilation going in my shop. Just before spraying, I ran my gloved hand along the inside of the hull to make certain it was dust-free.

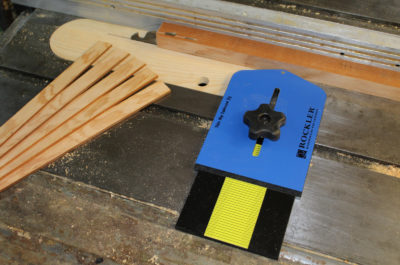

Whether sprayed or applied with textured rollers supplied by the manufacturer, the truck-bed liner paint creates a thick coating with a textured non-slip surface.

Following instructions, which called for over 10 minutes of constant mixing with the paint paddle in my cordless drill, I added tint, then catalyst, to the bed liner paint. To apply the coating, I used a gravity-fed spray gun and a 1½-gallon hopper connected to a 10-gallon compressor at 120 cfpm (cubic feet per minute). I used a a 1/8”-diameter texture tip on the spray gun—the larger the diameter on the tip, the more texture on the finished surface. The 10-gallon capacity of the compressor made it easier to do long sweeps with the sprayer without the compressor motor constantly running.

I went through a lot of nitrile gloves—the coating that got on them got sticky rather quickly. An hour after finishing the first coat I repeated the process. Cleanup took gallons of MEK and acetone. If you get the kit with the disposable rollers, a quart of MEK or acetone should suffice—much kinder to the environment. In retrospect I would have saved time, money, and solvent if I’d bought the kit and rolled the finish on.

The coating is quite thick, concealing imperfections and wear and tear in a well-used boat.

The results speak for themselves. Spraying all interior chines, corners, and edges prior to the sides and bottom effectively softened and hid 15 years of dings, scrapes, and small gouges that I had filled, sanded, and painted in previous years. I could see them before spraying, but they are now under a uniform, consistent, and virtually impermeable surface. The marked contrast between MAC’s unrefinished seat and the new bed liner reminds me of how worn my old boat was looking. I plan on fastening a varnished mahogany plank on top of the old plywood seat to complement the gunwales. With my old dory given a new and very appealing finish, I look forward to taking an overnight rowing/beach-camping trip with my 11-year-old grandson and seeing how the truck-bed liner holds up to the sand and gravel we’ll bring aboard when launching from the beaches.![]()

Dale McKinnon began rowing in 2002 at the age of 57, and in 2004 rowed solo from Ketchikan, Alaska, to her home town, Bellingham, Washington. In 2005 she rowed from Ketchikan to Juneau. Her previous articles for Small Boats Monthly include rowing the Columbia River and the Columbia River estuary, how to row rough water, and reviews of NewGrips and CrewStop rowing gloves, Exped sleeping pads, and the Devlin Duckling 17 and Fairhaven Flyer.

Monstaliner is only available from the manufacturer and shipped only to the US and Canada. A gallon of base coat plus catalyst for spraying runs $128.60 and the tints, sold in one-pint cans, cost $18.50 to $48.75. A gallon roll-on kit costs $145.40.

Is there a product that might be useful for boatbuilding, cruising or shore-side camping that you’d like us to review? Please email your suggestions.

Was one gallon enough for your dory?

I have used several truck bed liners for small-boat interiors, including professionally applied RHINO, etc. So far the best and best value is Al’s Truck Bed Liner. Found at the best price at R&E Paint Supply.

https://repaintsupply.com/al-s-liner-5701-gray-spray-on-bed-liner-p3946.html

I divide the material into 2 halves, roll on the first half quickly for good coverage, then spray the remaining from a texture gun. Works great. Key is preparation and quick application with help. There is a short pot life for the stuff.

Rick, yes, 1 gallon covered approximately 60 sq ft. The Devlin Oarling is 17+’ long, and at its widest is 22″ (chine) and 3 1/2+’ (gunwales). I eyeballed the square footage and ordered an additional quart to be safe.

Thanks for the headzup, Glenn! I’ll check it out for my Alaska boat!

Using the recommendations from this article, I plan to use Monstaliner on a new marine 12′ plywood skiff I am building. The company has been very responsive and helpful in advising me how to use small batches of the product with different colors. I plan to coat the bottom of the boat light gray and the rubbing strakes a dark green called Envy. The company—Magnet Paints—and Eric Rosenthal—the President and Technical Director—can be contacted at [email protected].

Good article but 120 cfps? That’s 7200 cubic feet per minute! A 10 gallon receiver would take 0.1114 seconds to fill! Do you spray cement as well?

Barry, you gave me a good laugh and possible retort (“of course! How else can I build my ferrocement dories”) but it’s a typo. Good catch! I meant “cfpm” —cubic feet per minute, not per second. [The correction has been made in the article text. Ed.] My writing “cfps” is an old, ingrained habit from when I worked at NASA/Ames Research Center. I wrote all the operating manuals for the supersonic Unitary Wind Tunnel complex: pressure vessels, boundary layer applications, and screaming-fast wind. Everything then was cfps. Sooo glad life has slowed waaay down.

Inspired, I believe, by the builder of Sage, I sought out a microsphere paint for the interior of my O’Day Mariner. The available version turned out to be a paint for basement walls at Home Depot among others. Two coats and the bare fiberglass interior, I feel, looks great. It seemed a little soft, and I’m sure is not as durable as bed liner but for bulkheads, inner hull, bottom of the deck, etc., it will cover, smooth, and not be as rough as I believe the bed liner will be. Simply another option.

Dale, I really liked your article. Right now I have a sand finish on my dory’s sole. Needless to say, next time around I will look into truck bed liner I read your bio. I discovered dories at age 59 with the purchase of a project boat. After a complete repair and refit I row in Santa Monica Bay here in Southern California. Most of the time I am the only rowboat for miles around. I have never loved a boat like my dory. Hours on the water are a quiet haven. The little boat is both seaworthy and great fun.

Hugh, as my grandson says, “dories rock!”

How hot does the liner get when exposed to direct sunlight?

Mark, I have never thought of benchmarking an acceptable temp for the truck bed liner. But I have taken my rowing clogs off and stepped over drybags to reach gear and haven’t noticed anything unusual, temp-wise. If I had sprayed black bedliner, then perhaps I would. However, the hull bottom is 6mm thick so I presume our cold water temps in the Salish Sea will mitigate solar heat absorption.

I am curious about prep work required for wood that has been previously painted. I got color chips from Monstaliner and all the literature that came with them talked about painting over metal, wood wasn’t mentioned when they were talking about things you can paint with this product.

Thanks for this. One of the things common “back in the day” was to do two different colors inside a small boat. One color up to the riser and a second color above it. Most of the wear on these beachable boats is on the inside bottom. If you have floor boards, rocks, mud and sand gets under them, and the floor boards get beat up. On RANTAN the floorboards are completely removable, and it is time for some attention, so I may just put a line around the inside at the top of the floor boards, mask it off and go for some liner there. I can see this on top of floorboards, or run up to over the chines or a few inches up on a floorboardless boat. And a quart is a lot less than a gallon. It looks like a quart would do 15 sq feet, which would be plenty for RANTAN’s bottom board and garboards. With a white interior, there looks like a tintable white is available. Added benefit for a slippery bottom looks to be built-in, even non-skid.