The first time Harvey Hamel retired as a contracts director for a Fortune-500 engineering and construction firm, he designed and oversaw the construction of the house he and his wife Leslie now live in. That was in 1999. The following year he went back to work with the same firm and then retired again in 2013. In the fall of that year he went to Port Townsend, Washington, less than an hour’s drive from his home in Kingston, for the annual Wooden Boat Festival. He had done some woodworking and had always been intrigued by the complexity of wooden boat construction. Seeing all of the traditionally built boats at the festival got him thinking that he might try his hand at boatbuilding. Before heading home, he bought a used copy of John Gardner’s Building Classic Small Craft.

Photographs by Harvey and Leslie Hamel

Photographs by Harvey and Leslie HamelTo make it easier to assemble the plank sections, Harvey built a long worktable along one wall of the garage.

Leafing through the pages of the book was all it took for him to get hooked on the idea of building a boat. It would be the perfect retirement project. Leslie was the daughter of a Coast Guard captain and moved frequently while growing up, but spent many of her summers at the family beach house on Camano Island, plying the waters there in a dory. She had fond memories of it, so Harvey decided he’d build a dory. He bought Gardner’s Dory Book and was drawn to the chapter on the Chamberlain gunning dory.

Prior to cutting the bottom to shape, Harvey set the frames and stems in place to make sure everything fit the outline he’d cut.

Harvey spent a few months poring over The Dory Book, soaking up the 71 pages of Chapter 5, and buying tools, hardware, and lumber. Gardner supplies detailed drawings of the dory’s frames, and since the six frames and the stems were the only building forms required, lofting wasn’t necessary. Except for a 1-5/8″ height difference the stems are identical, and the three frames forward are identical with the three frames aft, so Harvey only had to make one pattern for the stems and three for the frames. In anticipation of the work on the planks, he made a 19’ workbench along one wall of the garage.

With the garboards in place, a three-piece blank for the broad strake, scarfed and glued, was set on the forms to get the marks for its sheer-side edge.

Finding suitable lumber at an affordable price wasn’t an easy task. After searching for several months, he came across a Craigslist ad for white oak and clear, old-growth vertical-grain Douglas-fir, which had been properly stickered and stored in a warehouse in Lake Stevens, Washington, for 15 years. Harvey bought seven 20′-long 2x12s of the old-growth fir, two 12′ lengths of 2×8, and four 20′ lengths of 1×4 oak. Harvey milled the oak on his 12” planer for sawn frames, bent frames, stems, inwales, outwales, breast hooks, and false stems. He sent the fir to Edensaw in Port Townsend to be resawn into 1/2″ planking stock and 1″ boards for the bottom and thwarts.

With the hull complete, the gunning dory is ready for the interior accoutrements.

Harvey also bought some old planes, some new planes, a 14” bandsaw, and what would become a steady stream of clamps. Sawdust and shavings first fell on February 20, 2014, when blades and boards came together to produce the three-plank bottom. Harvey worked largely alone, sussing out each step in the construction by watching YouTube videos, reading blogs, and studying boatbuilding books. Progress on the uphill side of the learning curve was slow, and the project dragged out for months, then years. The stream of friends and relatives who visited the shop slowed to a trickle; they gave up asking when the boat would be finished.

Four years in the making, ODYSSEY is finished and ready for the water.

Each boatbuilding mystery that Harvey had to solve led to what he called a “sabbatical,” and then he’d eventually find a solution and return to the project. In December 2015, he had finished the planking, a significant milestone, but after he flipped the hull right-side up to work on the interior he was confronted with a whole new set of challenges: steam-bending frames, fitting the two breasthooks, and springing in risers, inwales, and outwales. Overwhelmed, he took a prolonged leave of absence. It came to an abrupt end one night in June 2016, when he bolted awake at 2 a.m. hearing a voice in his head shouting, “Just build it or burn it!” That morning he got back to work on the boat.

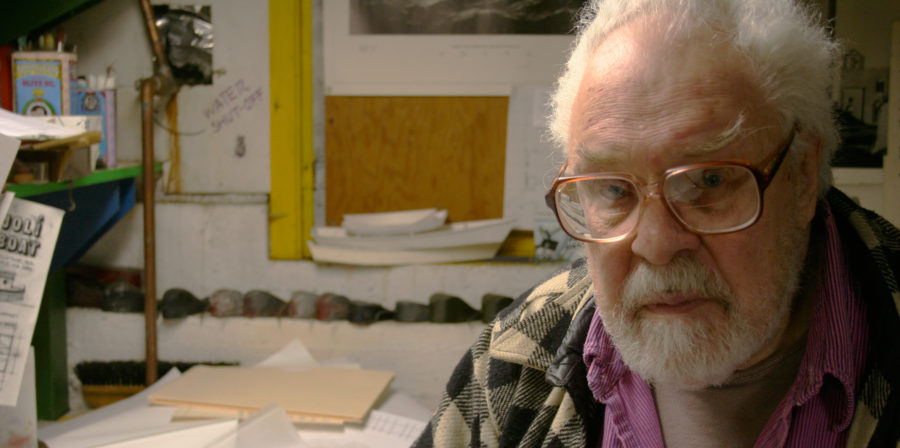

On a cool October afternoon, Harvey takes to the oars and glides gracefully into retirement.

As the project neared the end of its fourth year, it became clear that it would come to a successful completion and the boat was going to need a name. Leslie, mindful of the long and transformative journey Harvey had made to turn a stack of lumber into an elegant boat, came up with ODYSSEY.

At the end of the project Harvey began to feel his efforts had breathed life into lumber, screws, rivets, and varnish and in spite of all of the difficulties, the build had been the best way to begin his retirement. It had kept him healthy in mind, body, and spirit. His only regret was that he hadn’t started building boats 60 years earlier.

This time he has decided he’ll stay retired.![]()

Have you recently launched a boat? Please email us. We’d like to hear about it and share your story with other Small Boats Monthly readers.

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.