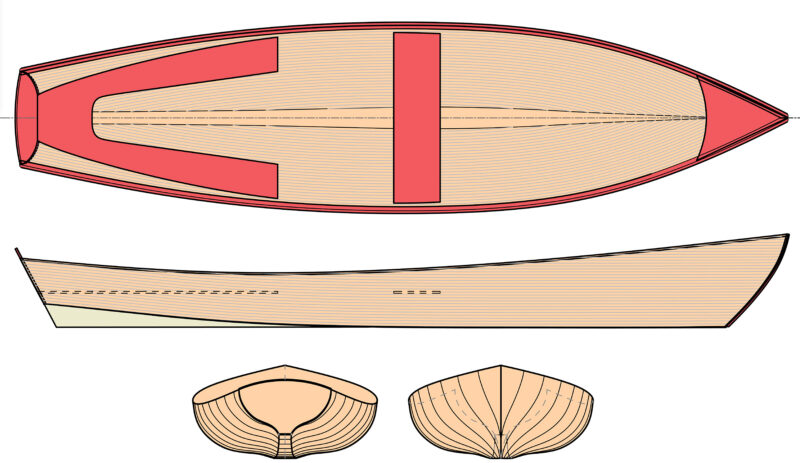

The Newfound Wherry, which began in 2004 as a rowboat and now has an add-on sail package, was created by Michael Vermouth, the founder of Newfound Woodworks of Bristol, New Hampshire. The design went through several modifications of the sail placement and centerboard in 2007 but was laid aside in early 2008. When it was resurrected in the fall of 2022, I built the updated version—equipped with a daggerboard and a larger spritsail—with the help of the Newfound Woodworks team and the Chase Small Craft team of Saco, Maine.

I bought the plans and complete kit provided by Newfound Woodworks. The kit came with a bundle of 18′ strips of western red cedar, northern white cedar, and Alaska yellow cedar for the hull; oak and ash for the tiller, keel, skeg, and daggerboard; a strongback and precision-cut forms; fiberglass and epoxy; varnish and hardware needed to build the boat. The plans consist of two 2′ × 3′ blueprints that clearly depict how the boat fits together, a 31-page step-by-step instruction book with dozens of detailed colored pictures. The large-format blueprints are generated by a computer-aided design program that provides information regarding spacing, angles, length, and specific assembly details.

Newfound Woodworks

Newfound WoodworksBuilding the hull upside down, the strips are laid from the sheer up to the keel, glued to one another and temporarily held in place with staples through to the forms.

I also purchased a Newfound Woodworks Pre-Kit: a 75-minute strip-building video instruction DVD with more than 100 detailed color photos of all phases of construction, a fiberglassing video instruction DVD, a CD with dozens of construction pictures, and Woodstrip Rowing Craft: How to Build, Step by Step, a 288-page color-illustrated how-to book by Susan Van Leuven.

The Pre-Kit gave me ample guidance to build the boat. As questions arose, the Newfound Woodworks team was always available, friendly, and ready to help via a phone call or email. The Chase Small Craft team had developed the wherry’s sailing rig and helped me build the spruce bird’s-mouth 10′ 1″ mast as well as the sprit and sprit boom in a three-day seminar.

While I had already built three of Newfound’s kayaks, constructing the boat is straightforward and requires only basic woodworking skills. After assembling the strongback and positioning the forms 12″ apart (which took me a day), the transom is attached to a form at the stern end of the strongback. Next, the inner and outer stems are laminated, followed by shaping the inner stem and attaching the bottom board before stripping begins. The bead-and-cove cedar strips are attached from the sheer up to the keel and glued to one another. Once the strips are attached, planing and sanding fair the hull. The bow’s outer stem is glued and screwed in place, then shaped. The hull is sheathed in 6-oz ’glass and epoxy: a first layer to the hull exterior from the keel to the waterline, and a second layer for increased strength. The exterior required three filler coats of epoxy to smooth out the fiber weave. A layer of bias fiberglass is applied to the keel and skeg from the transom to the tip of the outer stem at the bow.

Jim Creighton

Jim CreightonThe timeless interior layout is defined by a pre-assembled wrap-around bench seat in the sternsheets, two solid cedar thwarts, and the daggerboard trunk.

Once the exterior is sanded smooth, the hull is lifted off the forms and flipped over for cockpit fitting. The interior of the boat is sanded and faired prior to applying a coat of epoxy and a layer of fiberglass and bias ’glass at the bow and the perimeter of the transom. Only one coat of epoxy is needed over the fiberglass, as the texture of the fiberglass weave is helpful for traction in the interior of the boat.

The kit includes a pre-cut U-shaped marine-plywood bench cockpit. Two 9″ × 48″ Spanish cedar thwarts brace the daggerboard trunk, which has a 10″ slot in its forward end for insertion of the daggerboard. The daggerboard has holes drilled at 4″ intervals to allow for a pin to adjust its depth in the water. The foredeck is built with two shaped pieces of 6mm okoume plywood, which have circles cut halfway into the ply to properly place the opening for the mast. The deck is covered by cedar strips and sheathed in fiberglass. A piece of 2″-thick hardwood is epoxied into the hull on the centerline to serve as a maststep that will set the mast at a 5-degree rake.

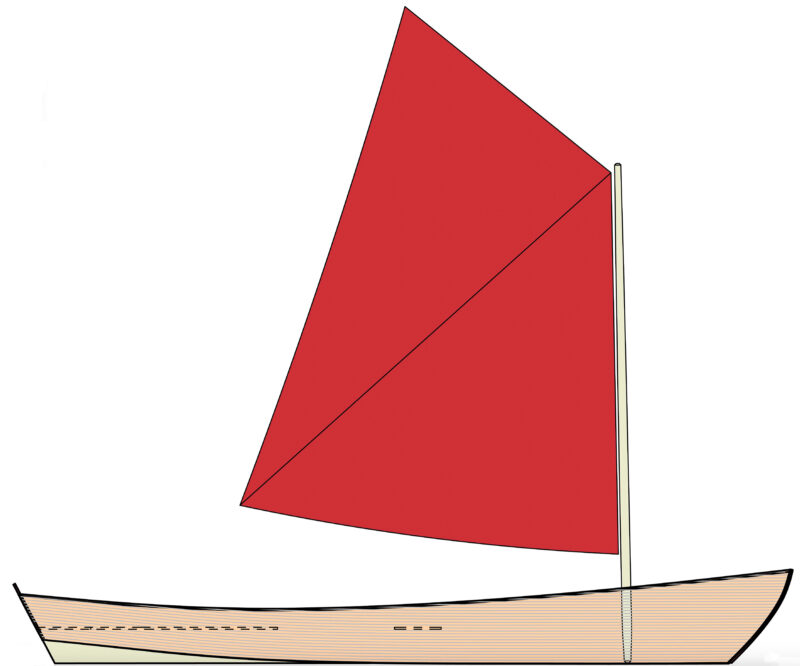

Working in my free time, it took six months for me to build the Wherry. When construction was complete, I put four coats of varnish on the deck and on the hull. The 95-lb Wherry tows well and glides off the trailer easily. To rig the sail, the mast is guided through the opening in the foredeck and seated into its step. The sail is permanently attached to the mast with a 1⁄4″ line which wraps around the mast and through eyes in the sail. Once the mast is set in the foredeck, the sail is hauled to the top of the mast and the halyard is anchored by a cleat located on the aft edge of the foredeck. The sprit is 8′ long and 1 1⁄2″ in diameter. I opted to add a 7′ boom to the rig to spread out the foot of the sail for better downwind performance. The ends of the two spars have 2″-long notches to accept snotters inboard and loops of line at the clew and peak on the outboard ends. Stepping the mast, raising the sail, and setting the boom and sprit is a simple process that takes me less than 5 minutes.

Jim Creighton

Jim CreightonEven in light airs the simple boomed spritsail powers the boat smoothly through the water. Note the partially raised daggerboard held in position by a pin slotted into holes drilled through the board at 4″ intervals.

The hull provides plenty of stability for standing in the boat, without feeling unsteady even with a 75-lb Labrador retriever moving about. The cockpit is well appointed for daysailing and there is plenty of room for two sailors, a large dog, a cooler, and a picnic basket. Four adults could fit comfortably with plenty of legroom.

Newfound Woodworks

Newfound WoodworksInitially meant for rowing, the Wherry has fine ends and is sensitive to weight in the sternsheets. The crew here, seated amidships, could improve the trim by sitting farther forward to balance the skipper seated well aft.

When the wind is up and the main is trimmed, the Wherry picks up speed quickly and handles well on a reach or closehauled. It is fun to sail in light or heavy winds, although the boat tacks best with wind speeds over 5 knots; below that it can get sluggish. We have sailed in winds gusting to 10 knots, and control and maneuverability improve as the wind speed increases. The boat performs well in light and moderate wind with minimal splash over the bow. The kick-up rudder blade has enough bite to turn the boat in all the current and wind conditions we have encountered.

The boat tacks well with the skipper in the sternsheets and the crew on the forward thwarts. I placed cleats 2″ aft of the after rowing station’s oarlocks to assist in mainsheet control. The daggerboard is adjustable as needed for water depth, wind, and point of sail. Fully deployed for reaching and beating, it keeps leeway to a minimum.

Mike Kilian

Mike KilianConceived as a rowboat, the Wherry performs well under oar. With one oarsman and no passengers the aft rowing position provides the best trim. With two rowers or a passenger in the stern, the forward rowing position can be used.

When the wind dies or if I want to go rowing or fishing without the sail, I use a pair of 7′ oars as auxiliary power. Each of the two rowing stations has its oarlocks positioned 14″ aft of their respective thwarts. The boat was originally designed as a rowboat and performs exceptionally well under oar power; it glides straight and true. With every stroke the Wherry seems to leap forward as it slips through the water. It maneuvers easily. When there is not enough wind for sailing, I take the boat out for a satisfying workout or to catch fish in local lakes.

Newfound Woodworks

Newfound WoodworksWith a family crew aboard, the Wherry trims well and glides well.

I thoroughly enjoyed the experience of building the Newfound Wherry. It is ideal for an intermediate craftsman who loves to sail on lakes and bays. It has proved a perfect vessel for family outings, picnics, and adventures on the inland waters of New Hampshire.![]()

The Honorable Jim Creighton is a retired Army colonel whose love of the outdoors led him to Antrim, New Hampshire. He serves as a state representative in the New Hampshire State Legislature and works as a member of the Crotched Mountain Ski Patrol. He is a leadership coach at the Tuck School of Business at Dartmouth College and runs a small wilderness guide company, Ursa Major Northeast Guides, LLC, which provides healing experiences for the Wounded Warrior Project and experiential leadership courses for Tuck and other schools. Jim spends his winters in his basement where he has built three Newfound Woodworks cedar-strip kayaks and the Wherry. He lives on the North Branch River where he paddles his kayaks to prime fly-fishing spots almost every day during the summer. He built the Wherry at the behest of his wife, Lieutenant Colonel (Retired) Tamasine Wood-Creighton, who has renewed her lifelong love of sailing. The boat is named SEANMATHAIR—grandmother in Irish—in honor of the skipper’s grandmother, Anne Nee of Rosmuc, Ireland.

Newfound Wherry Particulars

LOA: 16′ 9″

LWL: 15′ 1 3⁄4″

Beam: 48″

Depth: 15 1⁄3″

Draft: 6 3⁄4″

Weight: 98 lbs

Displacement: 700 lbs

Sail area: 50 sq ft

Plans ($160) and kits ($3,785) for the Newfound Wherry are available from Newfound Woodworks. An optional sail package will be available Spring 2024.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats readers would enjoy? Please email us.

Beautiful Vessels!