To do efficient and accurate work on a table saw, there are several accessories required beyond the miter gauge and the rip fence that ordinarily come with it. To secure feather boards, stops, and special fences, I’ve used clamps to hold them in place, but the undersides of the table and its extensions didn’t have flat surfaces to accommodate clamp jaws. The same problem makes it difficult to clamp accessories to my bandsaw and drill press tables. When I happened upon Magswitches on the web, they seemed to be the perfect solution, promising they could “secure custom jigs & fixtures anywhere on your table top” with just the twist of a knob.

The Magswitch company’s wide array of devices are built as magnets that can be turned on and off. Most of the products are meant for industrial use; the smallest of them, called MagJigs, are designed for the home woodworker. Inside the steel housings of a MagJig are two cylindrical magnets, one fixed to the housing and the other rotated by the knob at the top of the device. When the poles of the magnets are set north to north, south to south, the magnetic field is activated; when the poles are set in opposition, their magnetic fields almost entirely cancel each other. The steel housing takes care of the rest, and a MagJig that is turned off won’t even pick up fine steel filings.

Photographs by the author

Photographs by the authorThe MagJigs I bought include two 60s (upper left), one 95 (lower left), and a pair of 150s with a universal base and reversible feather board.

I bought three sizes of the MagJig: the 60, 95, and 150. The pair of 150s came in a Starter Kit with a Universal Base and the Reversible Featherboard. There is one more in the MagJig series, the 235. The numbers for each device refer to what the company calls its “magnetic hold force” in pounds. That force is for pulling the MagJig straight up from the surface and will vary with the thickness of the ferrous metal it’s attached to. A thin sheet of steel won’t capture the magnet’s entire field and the MagJig won’t have its full holding power. The cast-iron top of my table saw might not capture the entire magnetic field either, but because it is where I’d use the MagJigs, that’s the holding power that matters to me.

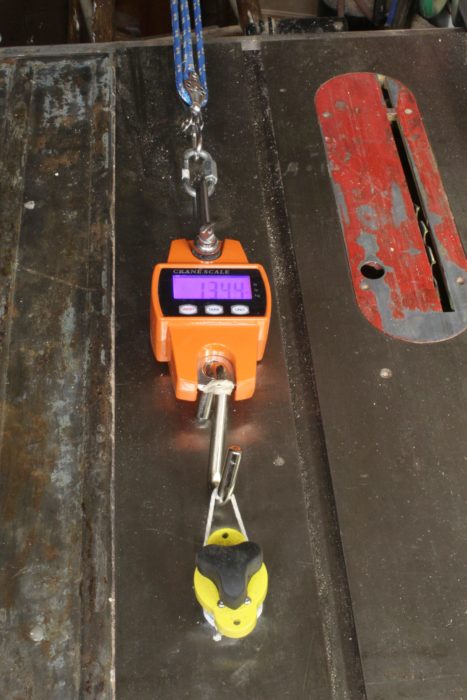

I tested the listed holding power using a hanging scale suspended from a boom vang. In all cases, the MagJigs let go at forces less than listed. Those listings might be more accurate on a thicker table, which can capture the full depth of the magnetic field.

To test each MagJig, I used a digital hanging scale to see how much force it would take to pull the MagJigs off my table saw. I threaded a loop of nylon line through the magnet’s two mounting holes and used the scale connected to a boom vang to pull the MagJigs straight up from the table saw. The 60 popped off at an average of 31 lbs, the 95 at 62 lbs, and the 150 at 106 lbs. So for my purposes, the MagJigs all fell short of their nominal strengths.

The holding force that applies to the uses of the MagJig are lateral. I arranged the boom vang and the hanging scale horizontally to see how much force was required to slip the MagJigs sideways.

When using MagJigs for fences, guides, and feather boards, the holding force that matters is not vertical but lateral, so I anchored the vang to a point level with the table saw top. With a loop of cord around the base of each MagJig, I used the vang to pull it sideways. The 60 slipped at 9 lbs, the 95 at 16 lbs, and the 150 at 22 lbs. The company recommends that the MagJigs be used in pairs to keep forces from rotating them, so I made a loop for the feather board fixture with its two 150s holding to the table saw top. It slipped at 40 lbs.

I use the MagJig 95 to hold devices that I don’t need to count on to stay put. Here it is used to keep a vacuum hose in the drill-press table.

For practical applications I found the MagJig 95 and 150 useful in the shop. The 60 just had too little hold force; the note on the packaging—“secure custom jigs & fixtures anywhere on your table top”—overstated its abilities. The 95, fitted to a block of 3/4″-thick oak, made a useful stop for light work on the drill press. It also worked to hold a bracket for a vacuum hose. The 95’s packaging had a picture of a pair of them used with a feather board, a use I’d recommend only for light work.

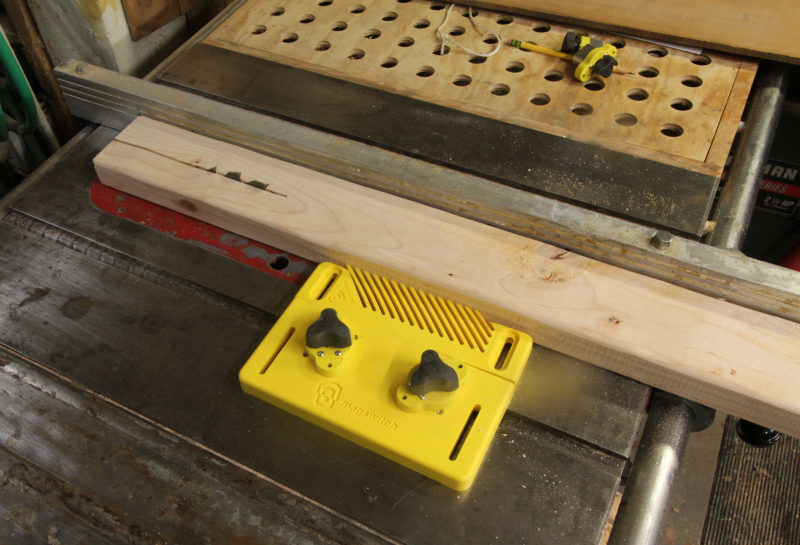

The feather board arrangement can resist about 40 lbs lateral pressure. The MagJigs are partially over the miter slot, but still have a firm hold on the table.

The 150s, with their base and feather board, lived up to my expectations. They hold the feather board in place with enough pressure to keep the workpiece against the rip fence. The feather board offers stiff resistance to kickback, but I could pull the workpiece backward (with the saw turned off). The feather board I made from a 2×4 doesn’t let the workpiece move backward.

The back of the universal base can be used as a fence for the bandsaw.

To use the base as a fence on the drill press, I had to use 1/4″ plywood under the workpiece to prevent tearout when drilling. The 3/4″ plywood I usually use is just as high as the base.

The universal base, with the MagJigs in place and the feather board removed, has a straight back edge that can be used as a fence on the cast-iron tables of my bandsaw and drill press. My favorite application of the base is as a guide for ripping on the bandsaw. I can saw to my drawn pencil line until I have the angle of the workpiece set to accommodate any blade drift and then set the base and activate the magnets with one hand.

A shop-made fence uses the 150 MagJigs and its minimal size is better suited to the small drill-press table than the universal base is.

The universal base with the MagJigs does have limitations. The placement of the device is limited to the area of the table it is being applied to. The base takes up some extra room, especially when the back side is used as a fence. You can make your own jigs with 3/4″ stock. The 150s require a 40mm hole, and a Forstner bit of that size is available with some MagJig sets. I used a 1-1/2″ Forstner bit and elongated it by drilling the first hole, shifting the wood by about 3/32″ and drilling again to shave off one side of the hole.

I’m not sure what I’ll do with the MagJig 60s. I may put a bridle and a cord on one to fish for drill bits that roll off the wall side of the workbench. Their bigger brothers will answer a higher calling in the shop.![]()

Christopher Cunningham is the editor of Small Boats Magazine.

MagJigs are manufactured by Magswitch and available from selected retailers. The MagJigs here were purchased from Amazon: the pair of 60s cost $39.99, the single 95 cost $26.50, and the pair of 150s with base and feather board cost $72.00.

Excellent review, Chris. Thank you. I like the versatility of the Magswitch. I have just 2 of the 150s as a kit. I make lots of jigs for the band saw. Putting the mesh sponge shelf liner under the jig and a thin soft rubber layer under the magnet means I’ve not had slipping problems. I also make the jig bases from 18mm plywood scraps so the magnet has good reach. I know now if I need more, stick to the good value kit.

Thanks for this review. My situation mirrors your own so when I first read about this product it seemed like a “wish come true”. Perhaps the 235 would stand up to the rigors of ripping on a tablesaw??

Thank you for this thorough review, Chris. At first glance it appears that these clever devices would be the panacea for awkward jig holding. However, after reading your review I don’t think I could depend upon these for any critical hold-downs. Considering the price, I think I’ll stick to homemade feather boards and jigs clamped by an inexpensive C-clamp with long jaws or bolted to track slots.