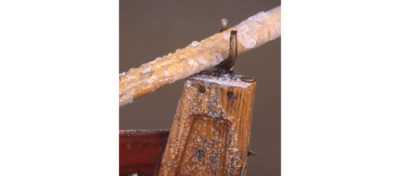

I had to take the Forward-Facing Rowing System apart to make a change before I fit it to my Whitehall, and in the process of removing the 8 stainless-steel nuts and bolts, I found that seven of the nuts wouldn't budge, and the only way to remove them was to twist until the bolts sheared. I may have twisted an odd bolt or two off in the past and chalked it up to corrosion, but to have seven out of eight new bolts go was odd. (In defense of the Forward-Facing Rowing System, the change I made was unique—the bolts don't normally need to be removed.) I thought the ends of the bolts might have been damaged, but some of the bolts that sheared had several threads extending out of the nut and they looked like they were in good condition. I didn't try a shot of WD-40—there wasn’t any sign of corrosion. Eight stainless-steel 1/4 x 20 bolts, seven nuts seized up by galling

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.

From the appearance of the threads in the picture, and the shape of the crown on the nuts, I would say it is highly unlikely that “galling” was the cause. These appear to be self-locking nuts that use a distorted thread to keep the nuts from working loose. The Installation instructions posted on the Forward Facing Rowing System Website say to use “locking nuts.” https://www.ghboats.com/options/accessories/forwardrow/installation/

I’ve included a photo here that will help identify the nuts. On the left is a replacement nylock nut I bought at West Marine. You can see the dark gray anti-seizing compound I applied before installing the nut and bolt. On the right are three of the nuts I removed from the rowing rig. The center nut is the only one of the eight to come off without sheering the bolt. All four nuts are identical, from the nylon insert on top to the triple plus-sign marking (+++) on the bottom (visible in the photo that ran with the article). The folks at Gig Harbor had the same problem I did and wrote: “Stainless steel threads will tighten in a nylock nut with no hint of binding, but don’t like to let go.”

I don’t often use distorted-thread locking nuts, but the ones I’ve seen are the type with an indentation on the side. I’ve done something similar with ordinary nuts by tapping a fine-pointed nail set to make a dimple or two in between the top of the nut and the bolt. While thread-distortion nuts cause friction to keep them in place, it’s my understanding that there’s not so much friction that the nut can’t be installed and by the same token, not so much friction that the nut can’t be removed.

Only the 2 on the right look like nylocks (with nylon inserts). The others do look like galling took place. I have experienced galling of stainless, but never with other metals.

They may have used LockTite thread lock on them. Sometimes a little heat will loosen the bond, otherwise the bolt will break off.

Here’s a closer look at one of the nuts. At “D” there are threads that appear to be clean. I don’t see any residue of any material on any of the nuts or bolts. At “A” there’s a dark line that is the gap between the sheared end of the bolt and the nut. At “B” that line ends and at “C” the metal appears to be smeared; there is no discernible gap between the metal of the bolt and that of the nut. There’s another nut where the bolt broke off at the second thread inside the nut and it too has places where the gap ends and the metal bridges the bolt and nut without interruption. It looks welded to me.

I too, have experienced galling but it seems only to occur with certain metals, namely aluminum and stainless steel. I have never experienced this with tool steel or galvanized nuts and bolts. I know from work many years ago in a metal fabricating factory that SS will tear and is particularly hard on dies and punches. I have often noticed that a punched hole in SS sheet will very often have a significant burr on the underside indicating that the “plug” has torn slightly as it was pushed out of the parent sheet. It is this malleability I believe, that causes the metal of the two parts under pressure-stress to marry or bond and become inseparable. The cold swaging of SS fittings to SS wire products actually bonds the two metals together as surely as if they had been welded. It is the same process being exhibited with the bolts.

Stainless-steel threads seem most prone to galling and anti-seize will generally prevent it. My worst experience was with a very expensive turnbuckle with both stainless studs and stainless barrel. In a hurry to rig a mast I tightened the turnbuckle without anti-seize on the threads and suddenly had all three pieces galled together. Replacing the turnbuckle was bad enough but in that the upper stud was swaged on to the main shroud it was necessary to replace both shroud and turnbuckle. I believe this is why many quality rigging turnbuckles have stainless-steel studs and bronze bodies—the dissimilar metals are less prone to galling. I also think nylock nuts are prone to galling in that the resistance of the plastic element brings more pressure on the thread to thread interface. And I’ve also found that setting s.s. nuts with a power wrench often can cause galling presumably because of the increased heat generated. But as has been said earlier anti-seize paste generally prevents the problem.

I too have encountered galling on SS bolts and nuts. I’ve never tried anti-sieze compound, however. I’ve also heard that stainless fastenings below the waterline, such as wood screws, will suffer “crevice corrosion,” but have not run into that. I

Galling, when you are tightening a nut, seems never to give any warning. The nut is going on fine, until you start to tighten it, then suddenly it won’t budge–and won’t come off, either. I agree, it seems to be some form of cold welding. Next time it happens, I’ll cut the assembly apart to see within the threads and try to understand what’s going on. I have never had it happen with any other metal. I would guess that with aluminum, you might be getting ordinary aluminum corrosion. I have, on parts of superstructure, used bronze screws and bolts with aluminum, and never discerned any problems with that.