We think the Drascombe Lugger is one the most versatile small boats ever built. Its designer, John Watkinson, sailed alone often but wanted a boat that his family “could enjoy, and to do this, the first requirement was that they should have complete confidence in the craft.” He set four criteria for the boat he would design: It had to be easy “for the family to handle on and off the trailer,” have “first-rate seakeeping qualities,” be a “good motorboat for fishing and pottering under power,” and be “lively enough for me to enjoy a good hard sail once I had put the family on the beach.”

Douglas Elliott

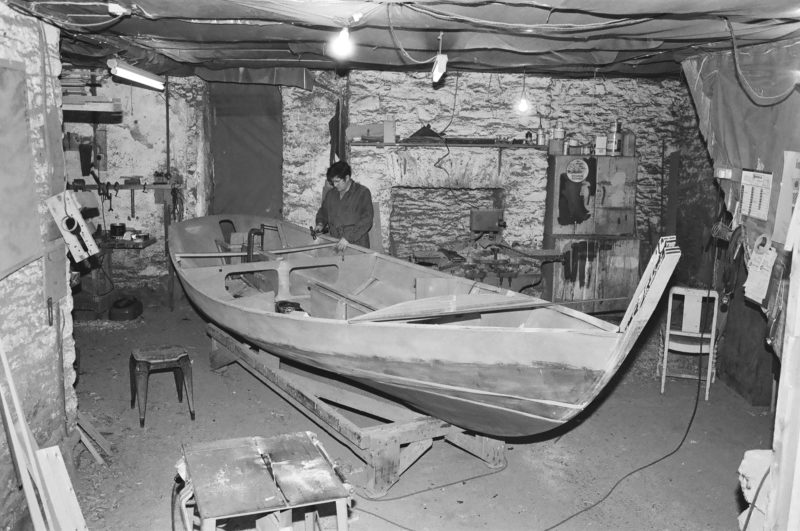

Douglas ElliottJohn Elliott and his brother Doug built this wooden Drascombe Lugger in their boatshop in 1978. The building at Yealmbridge in Devon, England, was 300-year-old flocking mill and furniture factory that was cold and drafty in the winter. The boat was built for the Rees family and named REESKIP (Rees’ ship) has spent all her life in Holland. A later owner renamed the boat ELLIOTT in honor of the builders after John passed away. The boat was built from BS1088 mahogany marine plywood and iroko hardwood with an all glued construction using phenolic resin adhesives.

In the photo, John is fitting the deck beams prior to the decks, sheer strake, and transom return being added. The hulls were built upside down on a jig on the floor above, then removed from the jig, turned right side up and the build continued on the ground floor. Every Lugger the Elliotts built was custom, so no two were identical.

These design criteria can be elusive when combined, but he hit the mark when he launched the first Lugger in 1965. He went into business making wooden Luggers in 1967. Fiberglass Luggers went into production in 1969 and are still being built today.

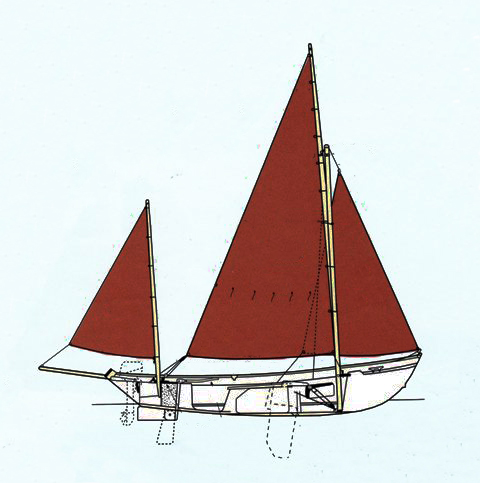

He based his Lugger design on fishing vessels that worked the choppy water of the English Channel. The sheer leading to a high freeboard forward keeps the crew dry and a broad beam makes it seakindly. The first Luggers carried a lug rig but switched early in production to a high-peaked sliding-gunter yawl rig. The boomless main allows the sail to be stowed out of the way and creates working space for in the middle of the boat.

The design met the requirements set by his wife, Kate, that the Lugger be “a day boat, so I could get home to a comfortable bed, have no boom to bang heads and have any engine fumes well out of the way.” Watkinson created a boat that his wife would enjoy and it drew the interest of others, and at the 1968 Earls Court Boat Show the first production boat sold within 20 minutes of the doors being opened.

Kent Lewis

Kent LewisTo keep the rudder at the ready, the authors’ Lugger, ONKAHYE, uses a piece of wood with a thin slot to keep the blade pulled up into its trunk.

Luggers are seaworthy boats in which many notable voyages have been taken. Ken and B Duxbury cruised from England to the Aegean and back in LUGWORM. Webb Chiles sailed his two Luggers, CHIDIOCK TICHBORNE I and II, 20,000 miles, which included a crossing of the Pacific and Indian oceans. Seakeeping qualities indeed.

Audrey’s family has owned Lugger ONKAHYE since 1982, and we have sailed her in lakes, reservoirs, bays, and harbors and even poked her bow into the Pacific Ocean on a day sail. The Lugger is 18′9″ in length and 6′3″ on the beam. She will float in 8″ with the galvanized centerboard up, and draws 4′ with the board down. The hull weighs 800 lbs. All of this adds up to a boat and trailer that can fit in most garages, is easily towed by a minivan or SUV, and is easy to launch.

Kent Lewis

Kent LewisA compartment in the aft end of the centerboard trunk houses a bilge pump. The trunk houses a galvanized steel centerboard and is wide and strong enough to stand unsupported by thwarts.

At the ramp, we can rig our Lugger in under 30 minutes, with one person rigging the boat and the other loading float kits, food, water, and spare PFDs under the seats. The second person’s primary job is to serve as the public information officer, as the Lugger always draws a crowd eager to ask questions. We usually step the unstayed mizzen first to get it out of the way, then step the 16′ mast and attach the jib stay to the roller-furling drum. The mast is easy for one person to step and all of the spars fit inside the boat for transport; it is easily lowered for going under low bridges. The main halyard and downhaul belay to pins on the mast thwart. Next, we tie down mainmast’s stays and run jibsheets through the fairleads to their cam cleats. We set the rudder in its case, employing a wooden chock we made to slip under the rudder cheek that holds it clear of the keel for launching. Moving aft, we rig the boomkin, attaching the mizzen sheet to the sail and bending the ensign onto a line flown off of the mizzenmast.

We keep the boomkin stowed during launching, lest it snag on something or someone. When the wind is light, Audrey pivots the boat 180 degrees while I park the trailer; it helps to have the boomkin stowed during that maneuver as well. On most days we sail off the dock, and in that case we’ll extend the boomkin, drop the rudder, put about centerboard half down and unfurl the jib. Once we are off the dock, we raise the sliding gunter gaff for a full main. I tidy up lines, drop a little more centerboard, and move aft to loose the mizzen. If we use the motor at all we usually shut off at this point and tilt it clear of the water in the neat transom cutout.

The Lugger has a great motorwell just behind the tiller and mizzenmast, so there’s no need to hang over the transom to work with the motor. A Minn Kota trolling motor performed well for protected areas but not extended cruises; a four-stroke Suzuki 6-hp outboard will take us up to hull speed at one-third throttle and handle any current or wind that we have encountered.

The jib is 30 sq ft, the main has options from 70 to 115 sq ft, and the mizzen carries 23 sq ft of canvas. The Lugger performs well under all points of sail but really enjoys reaching. She is not at her best pointing high, but can work to windward at a slow pace. With higher winds, it is best to release the mizzen during tacks. On a nice day we have run wing-and-wing, and on the bad days we have a multitude of options to set, reef, or furl the jib, main, and mizzen.

Drascombe Nederland - Michel Maartens

Drascombe Nederland - Michel MaartensCASTOR & POLLUX takes it easy flying only the jib and mizzen. The Dutch owner installed a tabernacle on the main mast to make it easier to lower. One of the oars is set in a transom-mounted oarlock in anticipation of shallow water ahead. The oar can be used for steering when the rudder needs to be retracted in thin water.

We almost never reef and we usually stow the mizzen first, but many folks prefer to drop the main and sail on the jib and mizzen. The boat is very stable and never feels like it is exceeding sensible limits. The wide beam is kind to beginner sailors, and there is plenty of room for four to move around the cockpit, tending to boat and sail trim without bumping into each other. Six adults is the maximum load.

With an experienced crew aboard, the Lugger is happy to take a lively sail; a hint of spray will come over the rail. The ride is comfortable with high bulwarks to lean against, and the boat feels sturdy. If water comes over the rail, ONKAHYE has a bilge pump built into the centerboard case. Heading back to the ramp the sails can be stowed and furled in a snap, giving us the opportunity to row a bit with the 8 1/2′ oars; the centerboard case provides a rowing seat for one set of oarlocks, and there’s a transom sculling socket to scull right up onto the beach.

Audrey Lewis

Audrey LewisThe authors’ Lugger, ONKAHYE (Seminole for Dancing Feather), was built in 1980 by Honnor Marine in Devon, England, and imported to Texas in 1982.

Our Lugger has required minimal maintenance over the years—the big jobs involved a touch of bottom paint, replacing the floor, and varnishing spars. That adds up to economy of ownership. We recently spent a day buffing the gelcoat, touching up the boomkin, replacing parrel beads, and whipping ends of a few lines. The teak gunwale, thwart, centerboard case cap, rudder case trim, and gunwale look phenomenal with just the right amount of patina.

Drascombe Nederland - Michel Maartens

Drascombe Nederland - Michel MaartensCASTOR & POLLUX was built in 1982. With main, mizzen, and jib set, Luggers carry 132 sq ft of sail.

The Lugger has a global owner footprint with the Drascombe Association, which produces a newsletter and hosts an online support forum. The Lugger started off with over 100 wooden hulls and is one of just a few boats make the transition to fiberglass while wooden hulls continue to be in production now. Drascombe just celebrated its 50th anniversary, and the Lugger is currently built by Churchouse Boats in England. Through the years over 2,000 fiberglass Luggers have been built, and the high quality has been maintained.

Gunter yawl, tanbark sails, belaying pins and a boomkin…how can we top that? As Webb Chiles put it, “the boat is built for performer and spectator.” For a half century the Lugger has kindled the spirit of adventure.![]()

Audrey Lewis has sailed her Lugger ONKAHYE for 35 years and pressed her husband Kent into service as movable ballast 24 years ago. The 1980 Lugger ONKAHYE is the flagship of their small-boat armada; her adventures can be followed on the blog Small Boat Restoration. Their review of Muck Boots is also in this issue.

Lugger Particulars

[table]

Length/18′9″

Beam/6′3″

Draft, board up/10″

Draft, Board down/4′

Weight/850 lbs

Sail area/132 sq ft

[/table]

Drascombe Luggers are available from Churchouse in the United Kingdom. They are priced at £18,250 (around $25,900 USD) and have been exported worldwide.

Is there a boat design you’d like to know more about? Have you built, bought, or adventured in one that you think other Small Boats Monthly readers would enjoy? Please email us!

Anyone know if there are plans available for a home build of this design?

Sorry, the Watkinson family stopped allowing plans to be sold many years ago. If you would like more information then please contact me through Drascombe by Churchouse Boats in England, and I will be able to help you

Sharon GH

[email protected]

Hi,

François Vivier sells plans for the Lilou 2 sailboat, it’s almost exactly the same as the Drascombe Lugger.

Dennis,once there were plans for a Lugger clone on the Web, called “Project Paltus” . If I remember it right, it was first published in Russian language in cyrillic letters, but it came with full plans. Later on an English translation occurred, but I can’t find in on the web nowadays. It was not exactly a Drascombe Lugger, but close enough.

Project Paltus in English!

http://heretics-guide.atwebpages.com/page04.htm

For more information on the Drascombe line read “50 years of Drascombes.”

The authors write well about a fine boat and the pleasures of sailing. People considering buying an old Lugger would do well to upgrade the buoyancy to meet the requirements of the European Union’s Recreational Craft Directive. It also would be prudent to rework the centerboard so that it does not disappear into the hull if the boat turns turtle.

These recommendations are from the Marine Casualty Investigation Board (Ireland). The examiners reviewed the capsize of a Lugger and the death of the skipper. Luggers that were built before 1998 did not have to undergo stability or buoyancy tests. As a result, some Luggers capsize easily and are very difficult to right by anyone other than strong fit sailors. (“Safety Upgrade of Drascombe Lugger urged following Cork Tragedy,” Irish Examiner, June 6, 2015. )

The people at Honnor Marine, which builds the Devon Lugger (identical to the Drascombe Lugger), can upgrade the buoyancy of old Luggers to meet the requirements of the Recreational Craft Directive. (Churchouse Boats does not list this specific option on their site.) Sailors in the U.S. might consider asking either builder for advice.

Duncan Wright

Philadelphia

At Churchouse Boats we do offer the upgrade if it is required by the owner.

Safety is a big factor in the building of the Drascombe range, and over the years have worked at increasing the required buoyancy for these boats.

I have a 1982 Drascombe Lugger that was built by Honnor Marine. I have stripped the hull completely and in the process of rebuilding and refurbishing everything. I am in the US, so stopping by the builder’s shop is not an option. I would love to know how much positive floatation is in the new boats, what is the weight, displacement, capacity, etc. I plan to increase the flotation, but what is a good target? In my searches the Devon Lugger is listed at 750 pounds and rated for 7 people and the European regs list the Churchouse Boat as 850 pounds and rated for 6 adults. That converts to approximately 990 pounds for people and personal gear. The regs say the rating is for a boat with its maximum rated motor and all necessary gear. So if the hull weighs 850, is that fully rigged with sails, electrical for lighting, spars, sails, oars, motor, fuel? I am guessing 850 is a rigged boat with rudder, centerboard, spars, but no motor, no sails, no oars, no battery, no fuel tank, no fuel. That gear is about 150-200 pounds, depending on choices. The 6-person capacity is based on all of that included. Based on all the info I can find, the all-up floating weight with gear and 6-people is close to 2,000 pounds. I have a lift in my shop and scale, so I can weigh all my gear and the boat, empty and all up. Hoping for better displacement capacity numbers so I know how many cubic feet of 2-lb foam or pounds/kilos/ of buoyancy to add, so I wind up with a properly loaded boat that meets or exceeds modern floatation standards, and one that is not overloaded with weight or gear. Thanks for the help.

Thanks for your comment.

Our boats are built with a heavier lay-up/GRP spec so there is no value in doing a kg by kg comparison with your 1982 Mk2 boat.

The plates and ratings are based upon EU legislation which only has a passing relationship with reality. For example, Category C is ocean/sea where the average mean wave height does not exceed 1.5 meters and, in EU-speak, a person is 75kg.

A Churchouse Boats Drascombe Lugger will weigh 355kg as a sailaway boat. This includes the spars, rigging and sails. My usual jest is that, if you need it to sail the boat, it is included. If you don’t, it isn’t. It doesn’t include any loose kit, engine, people, or gear.

The buoyancy we build into the boat is composed of:

Pre-formed expanded polyurethane buoyancy blocks filling 80% of the forepeak, the closed areas of side-benches, and each side of the outboard well in the aft compartment, as well as under the side benches in the open locker sections. This has been since 2017.

Looking at what you might do with your boat:

Think very carefully before deciding to use any form of foam blown in-situ. It is amazingly exothermic and can create great pressure. Where we use it, we blow it into potentially sacrificial molds and then build in the finished block.

For the forepeak and aft locker, a very efficient buoyancy is to use 1-litre plastic bottles. Sterilise them and glue the lids on, they will last forever and are easy to remove if you ever need to get to the inner face of the hull for repair. Our boats have a bulkhead across the aft locker, at the back end of the rudder trunking.

Your closed side-bench volumes probably already have slices of polystyrene in them but, if you want to check, cut for and fit some circular plastic screw-down hatches. None of the buoyancy tanks on a Drascombe are sealed. Their function is to contain buoyancy material.

If you are going to use polystyrene slabs up under the open side-bench areas, the trick to avoiding degradation is to wrap them, very tightly in 4 or 5 thicknesses of plastic food wrap. You may be able to get polystyrene slabs economically from a builder’s yard. They are widely used over here to insulate the cavities in brick walls or filling stud walls and that may be the same where you are.

It is not very often done but, if you have a mechanical means of holding your floorboards down (screws or turnbuckles), you could add further polystyrene slabs to the bilges. This not only adds buoyancy but also cuts down the volume of water to be bailed out after a swamping.

If you are going to undertake sharp-pencil calculations, don’t forget that any wood on the boat will take care of its own buoyancy. So do people – almost! Most lifejackets are 150 Newton (about 15 kg/33 lbs) which is enough to keep someone afloat! Everyone on the boat should be wearing one.

I hope this information is useful.

Sharon Geary-Harwood

Managing Director

Drascombe

Wonderful information, thank you for your reply! You have provided good insight and confirmed what I was thinking and the direction I was heading.

Regarding the incident in Ireland, we do not recommend that the centreplate is prevented from kicking up if need be, the idea being that the centreplate is to be freely allowed to go up and down when sailing in shallow water and in case it hits a rock, more damage could be done.

If you read the full report you will see that there were many contributory factors to the incident and fatality, it was nothing to do with the centreplate.

I conducted a swamp test on a wooden Drascombe Lugger in 1968 when working at Kelly and Halls in the early days of wooden Drascombe production, pre GRP. The requirements were different then than today of course, but we did offer buoyancy bags, or buoyancy cylinders of expanded polystyrene covered in acrylic canvas as an optional extra. Additionally, locker doors were also offered as optional extras, so with locker doors in place and buoyancy bags or cylinders also in place the boats will float quite high in the water, because for’d and aft lockers will keep a lot of water out of the boat. The swamp test was on a boat without the masts in place, but the rudder which weighs around 28 lbs and the centre plate which weighs around 100 lbs were on board the boat, there were no locker door fitted and it was quite difficult to get all of the air out of the lockers and fill them completely with water, but this was achieved by using a salvage pump to force water in and air out, I stood on the centerboard case top and the boat was still floating with its gunwale above the water, albeit a little unstable. I appreciate that it would be difficult to bail the boat out under those circumstances, but being a wooden boat, it would not sink with the ironwork and me on board. If there had been buoyancy fitted and locker doors in place, it would certainly have been possible to bail the boat out with a bucket if the centerboard case slot was plugged with some rags (such as a shirt) and the transom slot kept just above the water level by standing nearer to the bow. Obviously things have changed over the years and it makes good sense to incorporate buoyancy needed for safety, and boats being built today need to meet the current regulations.

Great information from everyone. As Doug mentioned, it is crucial to keep the centerboard cap above the water level, otherwise you can’t bail the boat out. It should not sink, but it will stay swamped, which is what tripped up Webb Chiles on his circumnavigation. He and the boat made it to shore eventually, just not together.

Cheers!

Hello, my name is Roger Oliver. I bought a partially built Drascombe Lugger from John Elliot in 1978. He built it through the first three strakes and I finished it off. I sold her a little while ago to buy a Sadler 25. My Lugger was called SPRAY and I am now searching for her. If anyone knows of her, please email me.

MK one Lugger safety improvements, having had a few Drascombes, both Dabbers and Luggers: I have fitted extra buoyancy in the side lockers and aft I used sealed one-liter plastic bottles purchased via the internet, they are cheap and fit into all the odd spaces available, also by counting how many you put in, you can easily count the extra liters of buoyancy you are adding, as I day sail and do not carry lots of camping kit, I fixed over the open side hatches 6mm marine plywood, screwed in place with self-tapping pan-head stainless screws, I also used a clear mastic sealer between the ply and the glass fiber moulding, having a drain plug fitted is a good idea for these side hatches which are now sealed, water will get in somehow, so a periodic check by removing the drain plug makes sure one is not lugging around gallons of water in the side buoyancy areas. The other good idea is to fix a center plate retaining rope to keep the plate down once in deep water, simply a rope fixed to the plate at the forward end so when the plate is down and aft in the center-plate slot it is tied around a decent-sized cleat on the rear of the plate box, make sure this is a sound fixing as it will take the weight of the plate in the event of a capsize. If sailing in shallow water I use the plate as a guide to not running aground so then release the safety line on the plate and then the plate will rise as it should, worth reading again the report on the capsizes in these excellent cruising boats, I like the Lugger and think it a very suitable craft for young families or old chaps like myself, but never too old to learn is a sound idea, so improve the buoyancy and have a plate-retaining rope and keep enjoying lugger sailing safely.

Dave Hart

Southwest Scotland

Check this video of Skipper putting the 1974 Lugger, ROAMER, that we restored through her paces.

FMI: Small Boat Restoration

Cheers,

Audrey and Kent

In Peru, I saw some native reed boats at Lake Titicaca that were using empty water bottles for buoyancy, as a replacement for a bundle of reeds that would get waterlogged and have to be replaced frequently. But they were still reed boats! They contained the bottles in netting.

I am toying with the idea of an inflatable bladder at the top of the mast to prevent turning turtle in a capsize. Would have automatic inflation if submerged, like a pfd. Not sure how to make it not look like an ugly bulge. Maybe it would work in a hollow metal mast. Have to avoid interfering with internal masthead wiring, of course. Okay, geniuses, help me out.