For many years I had searched for a boat that could sleep four, had decent headroom, a separate head compartment, great sailing performance, and a drop keel so that I could use a normal trailer. Most importantly, it had to fit in my 25′-long workshop. When I came across the Didi 26 by Dudley Dix, it seemed to have everything I was looking for, but it was just 1′ too long for my workshop. Then, I found his Didi 23, which had the same interior height and beam as the Didi 26 but was just 3′ shorter.

The plans had all the information needed to build the boat in any of several configurations. Dudley’s Guide to Radius-Chine Plywood Construction provides 21 pages of text detailing the method used for 16 of his plywood sailboats from 15′ to 40′, with 23 pages of drawings. The plans set provided enough instructions to get me started on the project, and the additional reference books cited by the designer were a big help.

I opted for the full-sized Mylar patterns for the bulkheads, keelson, and foils. There is also an option to buy digital files for having plywood parts cut by CNC machine. While the radius-chine boatbuilding technique would be faster than either strip-planked or cold-molded construction, I would suggest that an amateur builder gain some experience with the technique by building one or two smaller boats before tackling this one. Dudley provides his phone number and email address on his website, and he was very helpful in answering questions that came up. There are also several websites that show detailed photos of the build process of both Didi 26s and 23s.

Photographs by the author

Photographs by the authorThe long-cockpit version of the Didi 23, seen here, provides space for a four-person crew to be comfortably seated, either side of the mainsheet traveler.

The boat is built upside down on a ladder frame. The nine bulkheads plus transom are attached to the frame and slotted into the keelson. No temporary forms are needed. I fiberglassed the 9mm-plywood bulkheads and 12mm keelson before starting the assembly. The flat sections of the hull (the side panels and the two bottom panels) are 9mm plywood, which is epoxied and screwed directly to stringers and the bulkheads. The curved chines are laminated from two layers of 4.5mm plywood cut into strips about 10″ to 20″ wide. The strips are laid diagonally to the centerline to make them easier to bend across the four stringers that establish the curve. The plywood pieces are temporarily screwed in place while the epoxy cures. The decks are also of 9mm plywood laid over the stringers and bulkheads; the cabintop is stitch-and-glued 9mm plywood.

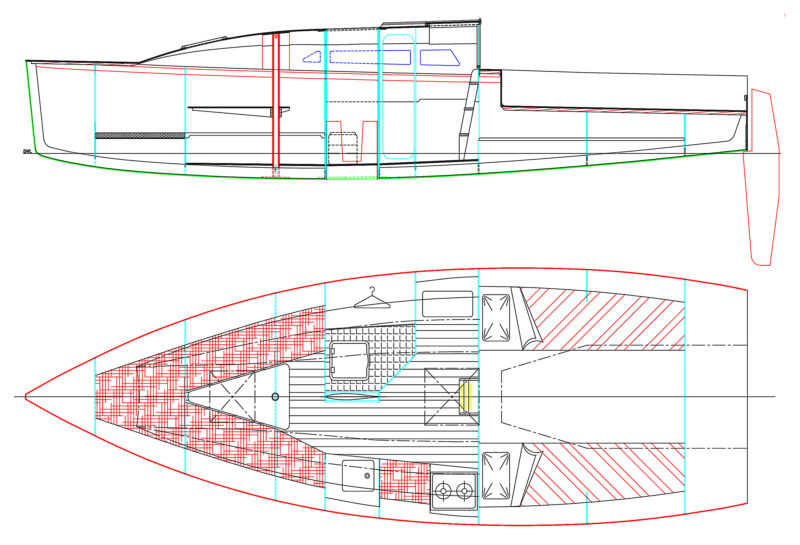

The Didi 23’s plans include options for a short cockpit with two double berths, and a long cockpit with one double and two quarter berths. I decided on the long cockpit. The two quarter berths are tucked in the stern beneath the cockpit side benches, and there is a roomy double V-berth up in the bow. I also made a few of my own modifications; most notable is the addition of a sugar-scoop extension to the transom, which allows for easier entry from the water and docks, and when the boat is on the trailer. This increased my boat’s overall length by 20″. I also added four windows in the hull to bring more light into the interior, and changed the shape of the companionway opening from parallel sides to angled sides, making it easier to get the washboards in and out. Finally, I created a double sliding hatch for the companionway, which has given us better access into and out of the cabin. It took me just under seven months to build and paint the outside of the hull, and then another 18 months for the deck, interior, and outfitting.

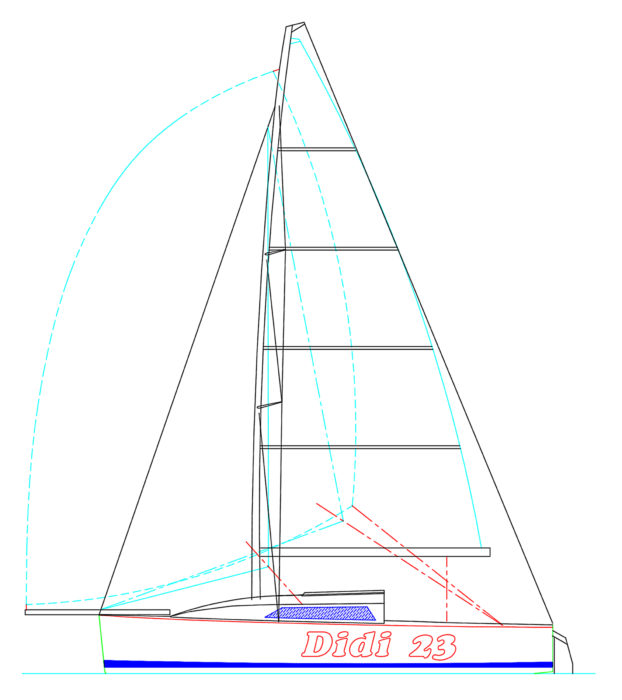

The fully battened mainsail, furling jib, fully adjustable running backstay, and tracked sheet leads allow for fine-tuning that enhances the Didi 23’s performance under sail.

For auxiliary power, Dudley lists options for hanging an outboard off the transom, or mounting a small saildrive diesel under the companionway. I installed the electric Spirit 1.0 Pod Drive by ePropulsion in a motorwell beneath the cockpit floor, where it can be retracted for sailing, trailering, or while at the dock. The 1kW motor is equivalent to a 3-hp gas engine, and at full throttle will push the 2,250-lb Didi 23 along at just under 5 knots. I typically motor at about half throttle to get the most out of the small battery that came with the motor. A small gas generator installed in a lazarette compartment gives me extra battery range and allows me to charge the house battery while cruising. At some point I will upgrade to solar panels and a larger battery for the motor.

There were two fractional rigs shown in the plans, one with a 33′ mast with three spreaders and one with a 29′ mast with two spreaders. I went with the shorter option since I didn’t want the expense and complexity of the three spreaders. With a roller-furled 100 percent jib and fully battened main, the Didi 23 has a sail area of about 240 sq ft. The plans show a retractable bowsprit for a spinnaker, but I decided to wait to install this at a later date.

The faux planking of the cabin and cockpit soles lends a touch of classic style. The companionway ladder lands aft of the enclosed head and wet locker. To starboard of the ladder are the instrument panels. To port is the galley with a single-burner stove and sink. Out of the shot, aft of the ladder, two single quarter-berths extend back beneath the cockpit benches.

With the retracting keel, the boat can be easily trailered. A custom tackle system mounted on the deck and operated by one of the self-tailing winches lowers and raises the keel and its 850-lb cast-lead bulb. However, even with the 6:1 purchase that the tackle provides, 850 lbs is a lot of weight, so I recommend going with larger winches than those shown on the deck plans. The overall weight of trailer and boat is about 4,000 lbs, so it can easily be towed by a small SUV or truck.

Thanks to its shallow draft of just 20″ with the keel raised, the Didi 23 can be launched at most ramps. Setup takes me 1 hour and 45 minutes by myself, and with a helper it takes about an hour. I use a gin pole attached to the base of the mast and the mainsheet blocks with the line led to a winch to raise and lower the mast. Using the main and spinnaker halyards as temporary stays, the mast can be raised easily by one person. The plans include a choice of fixed rudder or a rudder box with a daggerboard blade. I created a kick-up-style rudder that can be mounted like a normal balanced spade rudder. With the blade positioned below the sugar scoop, there is no need for a V cutout in the extension.

Beneath the fo’c’s’le berths there is substantial stowage space. The triangular plywood insert between them provides a platform for a generous double berth, and when raised up the mast support becomes a table with cozy seating for four. On an overnight it was comfortable for the three of us to sleep on the boat. It was a little tight when we were all trying to change clothes, but still bigger than a tent. The only change I plan to make is to add curtains for privacy.

The cockpit is roomy with plenty of space for four adults to spread out—six will fit but with four the cockpit feels spacious. Down below, the double V-berth is a good size and comfortable for two. The V cushion can be removed so that a table can be raised up the mast support. This provides a dining space for four, although it is cozy and most dining and socializing will take place in the cockpit in good weather—I have a portable butane burner for use outside. There is plenty of sitting headroom throughout the main cabin. The galley holds a sink and a one-burner stove, at which one can cook if seated on a stool or kneeling on the cabin sole, and there is additional space for a cooler and a chart table.

In the long-cockpit version, there are two large single quarter berths, and in the short-cockpit version there is a transverse double. Sleeping aboard is very comfortable with ample space in which to stretch out in any of the berths.

There is generous built-in storage under all the berths, and a little beneath the cabin sole. Between the first bulkhead and the bow there is a storage compartment that I converted to an anchor well that can be accessed from the deck. Finally, the partitioned head is just big enough for someone to squeeze into and close the door for privacy. There is a small wet locker area in the head as well, which I have been using as extra storage.

The fractional rig on a 29′ deck-stepped mast supports a working sail area of 240 sq ft. There is an option for a retractable bowsprit for a spinnaker.

On the water, the Didi 23 feels like a thoroughbred. The fastest I have sailed is about 8 knots in 10 to 15 knots of wind. But another Didi 23 owner tells me that he regularly beats 40′ boats in races in the Columbia River Gorge. The balanced rudder steers with an effortless ease. The boat tracks like it’s on rails, and with more than a third of the total boat weight in the keel bulb 6′ down, it is exceptionally stable.

My family and I have very much enjoyed the boat so far, and I highly recommend the Didi 23 to anyone looking for a high-performance trailer-sailer that is as well-suited to cruising as it is to racing around the cans.![]()

Casey Wilkinson owns Kea Custom Boats and lives on Bainbridge Island, Washington, with his wife and daughter. Casey started Kea Custom Boats in 2006 and has built more than 50 wooden boats ranging in size from kayaks, dinghies, and rowboats to speedboats and sailboats. Casey spent much of his career as a marine biologist and enjoys sharing his love of the marine environment with his family and clients. Casey has photos of the Didi 23 construction on his website.

Didi 23 Particulars

[table]

LOA/23′0″

LWL/21′8″

Beam/8′1″

Draft (min)/ 1′8″

Draft (max)/ 5′7″

Displacement to DWL/ 2,865 lbs

Sail area/263 sq ft

Headroom/4′3″

[/table]

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us!

A friend of mine has also the same Didi. He is a competition addict, so his Didi is more like a racing machine, but I agree the concept is pretty well balanced to be a cruising boat with very good performance characteristics.

He has a longer keel with less lead to make it lighter, custom full carbon mast and boom, all Dyneema rig, oversize composite sails, Code 0 and big gennaker. And I can confirm the boat is really fast. Can fully compete racing specials in similar size category, and definitely match bigger factory boats.

I remember when I helped him to fine-tune it on the water after he finished the build and I was the first one to steer it to planing. It planes like my old fiberglass 420 class dinghy :).

And also remember, when we pinned the mast to the water in a sudden storm wind gust during one 24-hour race. The boat can handle this pretty nicely.

I think the main issue was the retractable keel. When after few seasons the plywood keel just soak some water and after one season in the water he was unable to retract it (so it was needed to be cut with chain saw). After this experience, I think his keel is now fully carbon.

After two years in the water, my keel still lifts just as easily as when I put it in. The key was to be super careful about sealing it from water intrusion. Also I made mine from Sapele which would be far more resistant to water than plywood.