Several years ago, I built a stand for the only outboard I had at that time, and it made itself useful for maintenance and for flushing the cooling system with fresh water after an outing. When I got a second motor, I put off making a stand for it because I was running out of room and had the two motors share the same stand. That was awkward and I soon grew tired of shifting motors around. For off-season storage of the motors, a 2×4 screwed to the studs of the garage could hold the motors in a minimum of space and with no footprint at all on the floor, but the stand still took up a lot of space. If was going to have a stand for each motor, the second one had to fold so I could hang it up somewhere out of the way.

I made a few sketches, bought a few bits of lumber, and after a few false starts, came up with a stand that works well when I need it and takes up very little room when I don’t. I had seen several stands on the web that were made of 2×4s, but I felt that was overkill for the weight the stand needed to support, so I used 2×3 and 1×3 stock. The nuts, washers, and bolts are all 3/8″, though 5/16″ or even 1/4″ could work. The stand is tall enough to take my 2.5- and 4-hp Yamaha four-stroke outboards, weighs under 25 lbs, and can support my full weight.

Photographs by the author

Photographs by the authorThe base is made from 3/4″ plywood, 18″ × 24″, with a pair of 18″ 2×3s (all dimensions in the photographs are measured, not nominal) screwed along the long sides of the plywood. The swivel casters are screwed to the bottom corners. The ends of the 2×3s have 3/8″ holes drilled on the centerline and 1-1/4″ from the end. The holes on one end of the base are countersunk 1/4″ on the outsides, and on the other end the countersinks are on the inside faces.

The uprights are 34″ lengths of 2×3 with a pair of 21″ 2×4 crosspieces screwed at the upright tops. A 21″ length of 2×6 would serves as well for a crosspiece. The bottoms of the uprights are sawn and disc-sanded semicircles with 3/8″ holes at the centers.

The diagonal brace is made of 32″ lengths of 1×3. Each has at its top a 7″ length of 2×3 screwed to the outside face. The crosspiece is 3/4″ plywood cut to a width of 3-1/2″ and a length of 18″. Its ends are screwed to the 7″ 2×3s. The ends are semicircles and have 3/8″ at their centers.

The uprights are connected to the outside of the base’s 2×3s with 3″-long 3/8″ hex-head bolts with nuts and washers on the opposite side of the connection. The bolt heads are recessed in the base’s inside countersinks.

The diagonal brace has its legs bolted to the outside of the other end of the base. The bolt heads are set in the countersinks on the inside faces of the 2×3s.

The upright can be set and angled to match the transom of the boat that uses the outboard. The mark on the white tape is where a hole would be drilled through the upright and the brace. The hole should be oversized to create an easy slip fit for a 3/8″ bolt. I have a 13/32″ drill bit, but widening the hole with a 3/8″ bit or a rat-tail file would work, too.

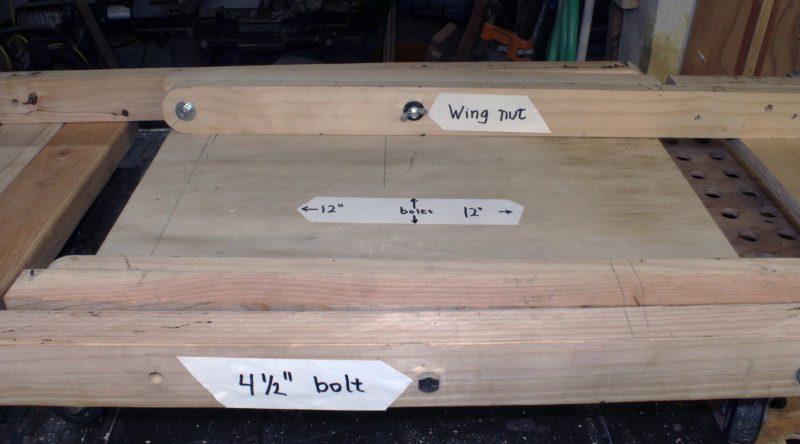

Because the stand is designed to fold, the 4-1/2″ bolt joining the brace to the diagonal gets a wing nut.

The transoms and motorwells on my boats are all plumb, so I drilled the hole through the brace and upright for a vertical mount.

When the upright and brace are folded flat, the 4-1/2″ bolts hold them against the base’s 2×3s. The hole is drilled at the middle on the base’s 24″ length. These holes also should have a loose slip fit.

To drill the holes accurately, I flipped the folded stand upside down. A piece of 2×3 with a hole drilled on the drill press serves as a guide. It gets the hole started centered and square.

Two 3/8″ holes at the tops of the uprights get a length of cord that is used to hang the folded stand out of the way.

A pail of plywood rectangles with matching slots makes a stand to hold a 5-gallon bucket for a freshwater rinse.

The plywood support is made tall enough to put the bottom of the bucket close to the fin at the bottom of the outboard.

While folded, the stand can be used as a dolly.

Christopher Cunningham is the editor of Small Boats Magazine.

You can share your tips and tricks of the trade with other Small Boats Magazine readers by sending us an email.

I was just doing research on such a system. Thanks.

Perfect timing for a great solution, I’m making one. Thank you.

Guess who needs one of these? I think I’ll use a furniture dolly as the base. Thanks for the great idea!

I built a stand similar to this one about 10 years ago, though without the folding feature. It has one annoying flaw: The 3″ casters do not roll easily, particularly over rough ground (such as that in the dirt/gravel Port Townsend boatyard). And the heavier the motor, the more roll-resistant they become. The problem is tolerable with my 60-lb. 4 hp Tohatsu, but very frustrating with my newer 92-lb 8 hp Yamaha.

I’m about to build a new stand with 8-inch cart wheels. And I probably will use Chris’s good idea for a folding system on this one because unless I have an episode of bad luck, I don’t need to use an outboard cart more than once or twice a year.

As with so many of the boat parts I’ve made, it’s entirely normal to have to build something at least twice to get it right.

The casters I used were a set I had in my scrap bin. They’re fine on my shop floor and in the garage, but they rattle a lot on the old sidewalk in between the two. 8″ cart wheels would be much smoother and removed for storage the cart would be compact for storage. Good idea, especially for the 92-lb outboard.

Really nice idea – the folding concept makes so much sense. As an aerospace engineer I also appreciate the ‘just enough’ approach to the 2x3s and 1×3! Just bought an 8hp outboard and plan to build one to keep the motor off the floor and aid while doing maintenance. The discussion on the wheels is helpful – I’ll probably make up a bracket for some larger wheels under the front end at least.