Hess family collection

Hess family collectionJack’s Columbia Star kit on the building jig: The numerous crosspieces make it possible to assemble the board without the use of staples or other fasters that would damage the wood.

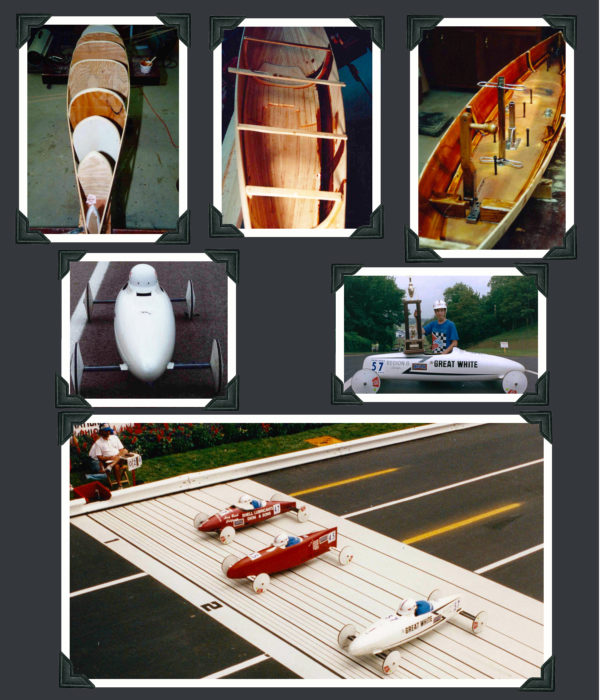

John “Captain Jack” Hess got an early start with strip-building, but it wasn’t with boats. Around 30 years ago, his sons Chris, Ben, and Jonathan, and his daughter Sara, all took an interest in Soap Box Derby racing and Jack guided them through the process of making gravity-powered Derby cars, each custom-fit to its young driver. With their sleek aerodynamic shapes and strip-built construction, the race cars were a lot like boats. The Hess kids built their cars with Sitka-spruce cove-and-bead strips either bent over ordinary molds or pressed into concave female molds. The interior surfaces were sanded smooth and sheathed with fiberglass and epoxy; after the top and bottom assemblies were finished, they were joined together and the whole body was faired, glassed, and painted.

The four kids participated in races coasting down tracks around 1,000′ long, reaching speeds around 30 mph. All four qualified for the Soap Box Derby World Championships. In 1992 Ben finished in 4th place; in 1984 Chris, at the age of 11, was the World Champion.

Hess family collection

Hess family collectionHess Soap Box Derby cars in the 1980s: spruce strips, fiberglass, and gravity.

Jack had always dreamed of building a boat and when he retired recently he had his opportunity. He thought he’d start with a plywood kit wherry and a strip-built kayak, but when he first saw a stand-up paddle (SUP) board go by his lakefront home on Lake Keowee in South Carolina, he thought: “Wow, that could really be something if made out of wood!” He put his strip-building knowledge to good use and began building SUP boards.

Hess family collection

Hess family collectionThe deck of AMERICAN STAR has a pattern that is a graphic interpretation of a totem-pole owl.

AMERICAN STAR is Jack’s first board, built around a Columbia Star frame from Cedar Boat Works. It measures 12′ by 30″ and is designed for flatwater paddling. The bottom starts out as a flat strip-built panel, later cut and curved to fit the snap-fit, interlocking 5mm plywood framework. Jack avoided the rows of staple holes often associated with strip-built boats by assembling the panel on an intricate strongback and clamping the strips together.

He also used clamps to glue deck strips to the curved sides and top of the framework. The work doesn’t go quickly applying one strip at a time and waiting for the glue to cure, but the unblemished finish was worth the extra time and effort.

Hess family collection

Hess family collectionClamping strips in place avoids the holes left by nails, but slows the work. Capt. Jack uses the time needed for the glue to cure to smooth other sections of the hull.

Jack built his second board for his dentist, an enthusiastic stand-up paddler. When Jack showed her pictures of AMERICAN STAR, she asked him to build a wooden board for her. Jack did a little research and chose the Chesapeake Light Craft kit, Kaholo, for her. Jack suspects that his dentist keeps the board displayed on a wall inside her waterside house near Charleston—she said her furniture isn’t as nicely finished as her Kaholo.

Jack Hess

Jack HessThe paddle for LOKA KAHOLO has a carbon-fiber tube at its core and the middle of its shaft has finger notches for a relaxed but secure grip.

LOKA KAHOLO is his third board. It’s another Chesapeake Light Craft Kaholo, built from a kit. The hull is stitch-and-glue sapele marine plywood but instead of using the same plywood for the deck, Jack created patterns in strips of Peruvian walnut, red mahogany, and the various colors of cedar. The deck fittings are walnut and include a lathe-turned cup holder. After the deck got its sheathing of glass and epoxy, Jack sanded the board smooth, finishing with 2000-grit wet sandpaper. A clear UV-resistant coating, polished to a high shine completed the job.

John Barnum

John BarnumLOKA KAHALO now plies the coastal waters of Maine.

LOKA KAHOLO was built for his neighbors’ daughter and her family. LOKA KAHOLO’s matching paddle was built by Jack’s good friend Tim Deppen of Deppen Paddles. It has a hollow shaft with a carbon fiber tube built in and weighs only 26 ounces.

Jack Hess

Jack HessFor Capt. Jack, paddle boards are as much a means of artistic expression in wood as they are functional watercraft.

Jack keeps AMERICAN STAR at home, but he hasn’t yet mastered stand-up paddling. He finds it rewarding enough to build boards as works of art and to watch his kids and grandkids paddling.![]()

John Barnum

John Barnum.

Have you recently launched a boat? Please email us. We’d like to hear about it and share your story with other Small Boats Monthly readers.

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.