It’s a natural impulse to protect our boats when they sit idle through the winter. We may not have the same affection for the trailers they rest on, but they also need attention while they wait for spring. Their tires, especially, benefit from protection from outdoor exposure.

Photographs by the author

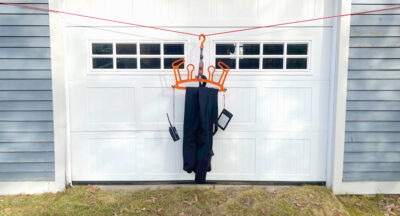

Photographs by the authorAny jack can lift a trailer carrying a small boat, but some jacks are not well suited to the work. A bottle jack (left) has a small base that’s prone to tipping. A floor jack (center) is more stable but doesn’t lend itself to being blocked up to get its arm within reach of the trailer, and the pivoting motion of the lifting arm makes the bearing pad prone to slipping out of place. The farm jack (right) has an exceptional range of adjustment and can quickly be set to contact a trailer frame before lifting begins. The upper clamp jaw can be removed to provide more clearance between the jack and the load.

Boat trailer tires don’t typically wear out. They don’t get anywhere near the same miles as a car or truck, and the time they spend out on the road doesn’t shorten their life, but rather, prolongs it: While on the road, a tire flexes, distributing the oils and other chemical compounds that are mixed into its rubber to keep it flexible and to protect it from ozone and ultraviolet light.

There are different degrees of protection for trailer tires. First is to get them up off the ground by elevating the trailer. Contact with moisture in pavement or soil can lead to dry rot in a tire’s rubber, and weight can create bulges in the sidewalls and flat spots in the tread.

A short jackstand set under the axle can hold the tire off the ground. While the jackstand is much easier to use than a stack of cinder blocks and timbers, working while under the trailer poses an element of risk that is best avoided by using jackstands that you can set beneath the trailer frame without having to crawl under it. Note the wooden shim used to keep the stand plumb on the sloped pavement and the chocks to prevent the wheel from rolling if the trailer drops.

Lifting a loaded trailer requires a jack. I started with a hydraulic bottle jack, but it only had a 3″ lift, hardly enough to raise the frame as high as I needed—as you lift a trailer, both the leaf springs and the tires decompress, effectively lowering the tires to the ground even as you’re raising the trailer. To use the jack, I had to crawl under the trailer to set it on blocks—for extra height—under the axle. After doing the lift, a precarious job at best, I dragged an assortment of blocks beneath the axle to support it so that I could remove the jack.

If the wheel is left on the trailer, a bag can be slipped over the elevated tire. To cinch the open end of the bag over the axle, tie a bowline in a length of cord. Hold the bowline on the right side of the tire and the cord on the left, then slip the cord over and behind the wheel. Circle the bowline end 360° clockwise around the tire while holding the other end stationary, paying out cord as it wraps around the axle. Slip the cord, or a bight of it, from the left through the bowline on the right, draw tight, and secure with a couple of half hitches. The red farm jack here is a 33″ version.

I switched to a floor jack, which has a long handle so I can operate it without crawling under the trailer. It has a 10″ lift but most of that range is needed just to get up to the axle, so it was not much better than the bottle jack. The arm of the floor jack pivots as it lifts and often slipped out of place. Both jacks made the chore of lifting the trailer unpleasant and risky.

The best points for lifting my largest trailer are at its back end, but they are inaccessible in its confined parking place. I trimmed a short length of 4×4 to fit inside one of the trailer’s crossbeams to provide a lifting point with clearance for the farm jack.

A farm jack makes the job much easier, safer, and faster. They’re inexpensive and come in a range of sizes. I found that a 33″ version is more than tall enough for all my trailers. With a farm jack I can quickly slide the ratcheting runner assembly under the bottom side of the trailer frame and then pump the handle to make the lift, all without crawling under the trailer. The runner’s ratchet is reversible so the trailer can be lowered with good control. However, once the pressure is off the runner, it drops to the base. I learned to keep a hand on the jack when that happens to keep it from falling over.

Taking the wheel off the trailer is the best way to protect the tire during the winter. With the wheels and tires removed, the adjustable jackstands supporting the trailer frame can be set to their lowest position for maximum stability.

Once the trailer is raised, you need to keep it raised. In the past, my trailer has overwintered on stacks of concrete and wood, but I’ve now replaced those with ratcheting jackstands. They are rated for 2 tons and their height is adjustable. If the trailer is on soft ground, I put the stands on a plywood base for a firmer footing; on my sloped driveway, I use shims to plumb the stands. Even with this finessing, setting up the stands is much easier than piling up the old cinder blocks and lumber offcuts.

With the trailer and tires elevated, you can add further protection by covering each tire with a purpose-made plastic bag and tightly sealing its opening around the axle (and the spare’s mount). This will reduce the effects of sunlight and precipitation and again slow the evaporation of the tires’ oils and antiozonants.

After the wheels have been removed, a heavy-duty plastic bag, secured to the axle with a zip tie, protects the hub and bearing from rain and snow.

A final measure is to remove the wheels, clean and dry the tires, including the spare, and store them indoors where they can be protected from temperature fluctuations and cold. Removing the wheels also provides an opportunity to inspect the wheel bearings and repack them if necessary.

Even with indoor storage, putting each clean, dry tire in a tightly sealed bag is a good anti-aging measure to take. However, when storing inside, caution is needed: tire rubber is adversely affected by ozone, and my local tire store advises keeping the tires away from “generators, compressors, furnaces, switches, sump pumps, and central vacuum cleaners”; the list could also include woodshop power tools, as their brushed motors can create the sparks that generate ozone.

After taking them off the trailer, I wrapped each of the tires in bags and used a compact electric air pump to pull air out of the bags before tying them closed with a cord. To elevate the stack of tires I made a plywood stand of interlocking rectangles and a disc to support the wheel just inside its rim.

Bagged tires can be stacked for storage. Be sure that they are inflated to their recommended pressure. To keep the bottom tire off the cold concrete floor, I made simple plywood stands to support the tires; if you have the space, you can also use a wooden pallet.

As the next boating season approaches, I’ll be eager to get my trailered boats back on the water. The farm jack and the jackstands will ease the transition, and the well-cared-for tires will have lots of life in them and give me peace of mind on the highway.![]()

Christopher Cunningham is Small Boats’ editor-at-large.

Farm jacks and jackstands are available from a wide variety of hardware and automotive retailers. I bought a 48″ jack from a local auto-parts store for $95, and the 33″ version online for $69. Jackstands, sold in pairs, cost around $30. I bought a package of eight Wheel Connect tire storage bags for $16. There are 55-gallon contractor trash bags that have the same 38″ width to fit tires with a diameter-plus-width of less than 37″.

You can share your tips and tricks of the trade with other Small Boats readers by sending us an email.

Join The Conversation

We welcome your comments about this article. To include a photo with your remarks, click Choose File below the Comment box.