After years of sailing Lake Superior and the Apostle Islands in my 30-footer, I was looking for a trailerable boat that I could sail summers in Minnesota and winters in Florida. My boatbuilding friend Jim Wagner suggested building one—an undertaking I would not have tackled on my own—and so I settled on Charles Wittholz’s “15 Foot Plywood Catboat.”

Its gaff rig allows for plenty of sail area (170 sq ft) on a mast only 20′ long. The shallow draft of 18″ (with the centerboard up) is a good match for both Florida’s shallow Gulf waters—where my wife and I sail in the winter—and the city lakes around our summer home in Minneapolis. The mast is stepped far forward, allowing for a generous cockpit that can accommodate six, and a small cuddy cabin with room for a portable head, a large cooler, and storage. A catboat’s beam is traditionally half its length, and our boat follows this rule: 7′ 4″ on her almost 15′ length. A hard chine contributes to the cockpit’s roominess and the boat’s overall stability.

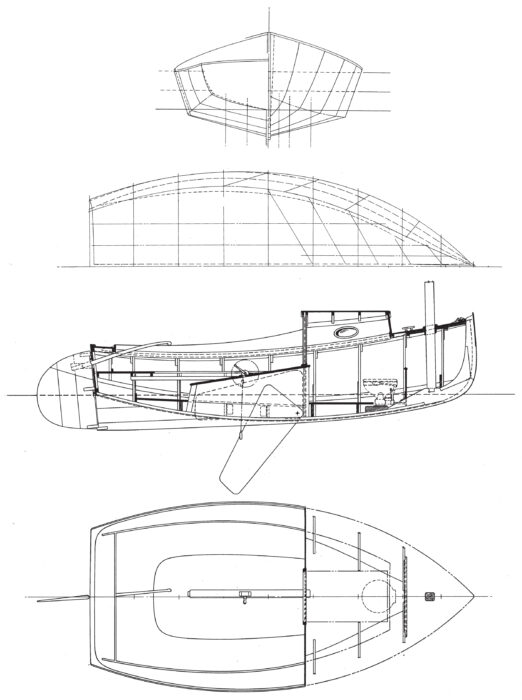

The plans, purchased from The WoodenBoat Store, include a page of notes from the designer and seven sheets of drawings with instructions, two sail plans, offsets for lofting, and options for inboard-engine and fixed-keel versions.

Al Watts

Al WattsThe hull was built upside down of 3⁄8″ okoume plywood on ash. The plans show the stem built in three pieces—stem, knee, and gripe—but we assembled it in one piece and shaped it with chisels and power planes.

Building the Wittholz 15

After Jim and I had built the strongback, we lofted the frames onto a 4′ × 8′ plywood sheet from the provided offsets. We used a different-colored marker for each frame and drew out the patterns from which to fashion and assemble the nine frames.

Once the frames were assembled, we temporarily fastened them to the strongback, then fitted the chines, sheer stringers, and keelson, for which we used ash in lieu of the Douglas fir or Philippine mahogany specified in the plans. The catboat’s stem is drawn with three pieces—stem, knee, and gripe—but we made it in one piece by stacking five layers of ash with staggered butt joints. Lots of chiseling and power planing were required to rough out the bevels for the plank ends.

While the detail of the plans and instructional notes were sufficient, some things are left to the builder’s choice. This was no problem for my boatbuilding partner, Jim, but it would have left an amateur like me scratching my head. However, under Jim’s guidance I was able to fill in the gaps in the information and even to make some of my own modifications.

Asli Iskeceli

Asli IskeceliThe plans offer lug or gaff sail plans. We chose the latter and have found the boat to be responsive, stable, and remarkably close winded.

The plans called for a 100-lb retractable 3⁄8″ galvanized steel-plate centerboard; we replaced it with one made of epoxied ash sections. We routed out a hole at the bottom of the board into which we poured 20 lbs of melted lead. I’ve found that this weight is sufficient to lower the board, and light enough that we don’t need a winch to lift it back up.

Wittholz specified traditional Sitka-spruce mast and spars, but instead, I custom-ordered a carbon-fiber mast and spars from Forte, a carbon-fiber tubing manufacturer in Ledyard, Connecticut. This reduced the mast’s weight from more than 50 lbs to around 20 lbs, which allows me to raise and lower it on my own.

The catboat’s transom is 1⁄2″ plywood framed with 7⁄8″ ash. The sides and bottom of the hull are planked with six sheer-to-chine and chine-to-keelson sheets of 3⁄8″ okoume plywood—two sheets for each side and two for the bottom. To build the hull, we first bent inexpensive thin plywood sheets onto the strongback and frame and cut them to create templates. Then, using the templates, we cut the hull bottom and side panels out of the 3⁄8″ okoume plywood. We then temporarily fastened the okoume panels into place, traced the fastening surfaces along the longitudinals, and then removed the panels.

Al Watts

Al WattsThe cuddy cabin provides shelter from inclement weather, some stowage space, and privacy when using the head.

Wittholz designed the boat in the 1960s, before the popular use of epoxy, and his plans called for bedding compound on all faying surfaces. We applied thickened epoxy to those surfaces before reinstalling the panels, again temporarily fastening them to the longitudinals with construction screws. Once the epoxy had hardened, we removed the screws. Construction of the keel followed, again using laminated ash with staggered butt joints.

About 400 hours into our build, we freed the hull from the strongback and flipped it right-side up onto the trailer for completion. This included construction of the centerboard trunk and barn-door rudder. For the rudder, the plans indicate three vertical pieces of 2″ mahogany or white oak, edge-bolted together and then tapered to a 1⁄2″ trailing edge. We edge-glued seven shaped horizontal pieces of 2″ ash, finishing the blade with a power planer and lots of sanding.

Al Watts

Al WattsSix people can sit in the cockpit in comfort and even the centerboard trunk doesn’t get in the way. Yet, when sailing singlehanded everything is within easy reach. The boom crutch has been a useful addition when raising and lowering the sail, and we fitted lazyjacks to catch the sail and keep it out of the cockpit as it comes down.

Any permanent screws used in the construction were stainless-steel, or bronze if they were visible. J.M. Reineck and Son fashioned the catboat’s gooseneck, and the rudder’s pintles and gudgeons. The Wittholz 15 plan calls for 300 lbs of ballast in small lead pigs placed between frames 5 and 6. Lead is expensive, but I was fortunate that a friend of Jim’s had just retired his larger boat and offered us whatever lead bricks we needed. We positioned ten 30-lb bricks in the bilge with ash supports to prevent ballast movement; straps secured each brick in place and allowed for easy removal for maintenance. Durable Tufnol blocks from R&W Rope were a fraction of the cost of wooden blocks and require little maintenance. The rest of the hardware and fittings were readily available from West Marine and local hardware stores.

Launching the Wittholz 15, GAVIIDAE

The catboat first touched water in a Wisconsin lake before completion and without its rig; it was watertight and glided along nicely, powered by its auxiliary Torqeedo 1103, a 3-hp electric long-shaft outboard. While trailering it to Florida for completion, hardly a stop for gas went by without drawing admiration, curiosity, and questions.

By the time we returned to Florida for our second winter there, we had completed the rig and were finally able to raise the catboat’s tanbark sails from Performance Sailing. All that remained was to paint the interior of the cabin, varnish the mahogany seats, flooring and trim, make some rigging adjustments, attach the catboat’s decorative nameboard, paint the spars, and install the homemade mahogany cleats.

Asli Iskeceli

Asli IskeceliWe christened the boat GAVIIDAE (from the Latin genus, Gavia, and family, Gaviidae, for members of the loon species) and sail her on both lake and Gulf Coast waters. Her large sail moves her in all but the slightest of breezes, and the 3-hp Torqueedo 1103 gives us good auxiliary power when the wind fails completely or we’re maneuvering alongside a dock or into a ramp.

Our Wittholz catboat took her first sail in Charlotte Harbor, Punta Gorda, Florida. In an 8- to 10-mph wind, she performed beautifully, achieving about 5 knots with a moderate heel, she was very stable and tacked surprisingly close (we estimated about 30°) to the wind. When we dropped the sail, it bunched over the boom and fell into the cockpit, limiting our visibility, so we later added lazyjacks.

On our return to the Midwest, we installed electrics including bronze navigation lights from J.M. Reineck, and a tricolor masthead light, all powered by a 12V battery. Back on Lake Superior, two other couples joined us for a sail, and we found the cockpit plenty spacious and comfortable for six people.

Building the catboat was an investment of money and time, but the experience was priceless. As a beginner boatbuilder I definitely needed the experience and assistance of my friend, as well as access to his well-appointed shop. The boat’s performance has lived up to all my hopes. If you are looking for a generous cockpit, a small cabin for storage, privacy, and shelter from bad weather, a boat that you can singlehand, that has classic lines, and is well suited to trailer-sailing, then Charles Wittholz’s “15 Foot Plywood Catboat” is the ideal boat.![]()

Al Watts tapped a lifelong interest in sailing later in life, first learning on small lake scows, then getting certified for bareboat chartering, then sailing his own sloop, LOON, on Lake Superior. He, his wife, and friends sail GAVIIDAE on Lake Harriet in Minneapolis and Florida’s Gulf Coast bays. Members of his Twin Cities Sailing Club enjoy the experience of a Cape Cod catboat, highly unusual in Minnesota waters.

Wittholz 15 Catboat Particulars

LOA: 14′ 11″

LWL: 14′ 4 1⁄4″

Beam: 7′ 4 1⁄2″

Draft (centerboard up): 1′ 6″

(centerboard down): 3′ 8″

Weight: 1,400 lbs

Sail area, gaff rig: 170 sq ft; lug rig: 157 sq ft

Plans for the Wittholz 15 Foot Plywood Catboat are available for $75 from The WoodenBoat Store; a digital study plan is also available for $1.99.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats readers would enjoy? Please email us your suggestions.

Al, as I read this the plans are on my desk in front of me! Glad you wrote this I saw your photo in Woodenboat and was dying to know more about it. I’ve been wanting to build the Wittholz Corvus 15 for years. Nice job! Dave

Thanks David, ‘glad it’s useful!