I have never been ambitious enough to master a vast array of knots. There are plenty of books filled with detailed instructions and photos for scores of complicated hitches and bends, but in practice, there are only a few simple knots that I use regularly aboard my boats. Quick-release tension knots, which can be drawn very tight and released instantly even when under load, are an extremely useful part of my repertoire.

SBM

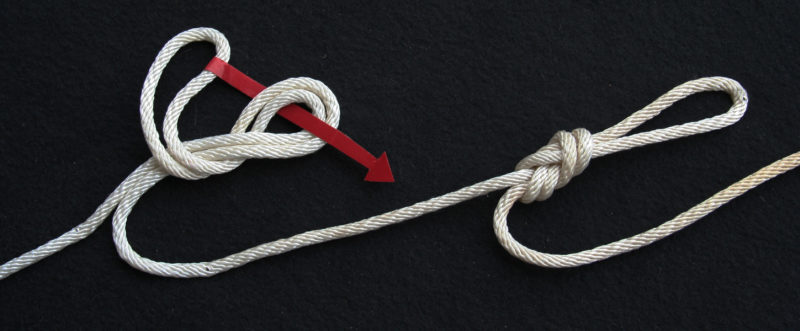

SBMThe common trucker’s hitch (shown loosely tied for clarity) has a slip-knot loop and two half hitches holding the tension.

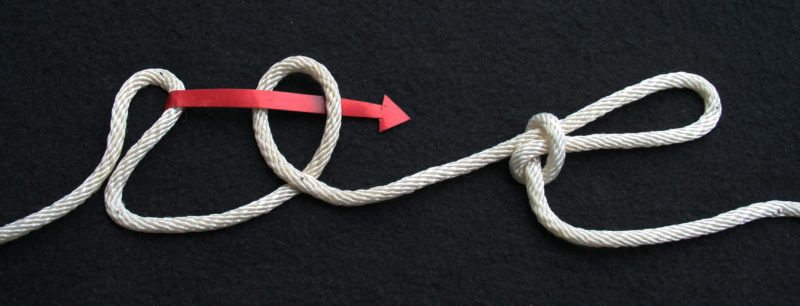

The tension knots I use are variations of the standard trucker’s hitch, which is used to secure loads on trucks or roof racks. Begin by forming a loop in the standing part of a line—a figure 8 on a bight works well. The trucker’s hitch often uses a slip knot that can be undone when it’s no longer needed, but for boat rigging, a permanent yet easily untied loop is better because for a line that has a single purpose you’ll want the loop to remain in the same place.

SBM

SBMA figure-8 on a bight forms an inline loop for repeated use.

SBM

SBMPulling the bitter end will create a lot of tension, with the loop of the slip knot and the anchor point (here, a screw eye at right). Pinching the working end of the line where it wraps around the slip knot will hold the tension as the knot is being completed.

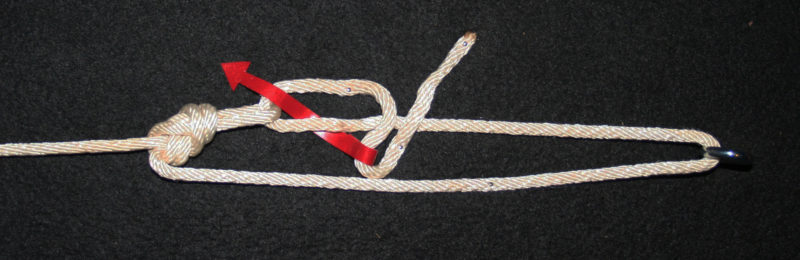

Next, take the working end of the line around an anchor point and bring it back to the loop. Pulling back on the working end after passing it through the loop creates a mechanical advantage that allows the line to be drawn very tight.

SBM

SBMThe tensioning knot is finished off with a slipped half hitch, snugged up with a pull into the figure-8 loop.

When you have the line as taut as you want it, pinch the working end of the line tightly where it wraps around the loop. With your other hand finish the knot with a slipped half hitch—a single half hitch with a bight rather than the tail of the line pulled through. Snug the hitch up by pulling the bight directly back toward the loop. If you pull in any other direction, you will lose some of the tension in the line.

SBM

SBMThe finished quick-release tension knot with a figure-8 on a bight and a slipped half hitch

This quick-release finish is especially useful on a small boat when you often have to act quickly, with one hand, or with cold fingers. The slipped half hitch can be released, even under extreme tension, simply by tugging the tail end of the line, which pulls the bight back through.

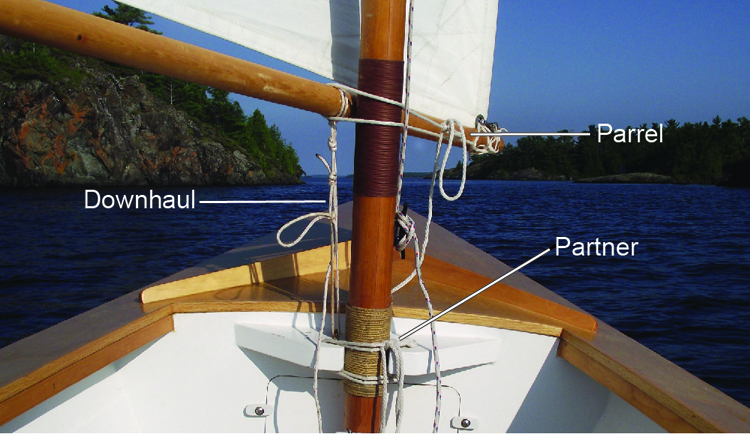

Tom Pamperin

Tom PamperinThree quick-release tension knots secure the mast and boom.

Variations on this system can be used to join two separate lines or the ends of a single line to create a very reliable high-tension attachment point. The downhaul for my balance lug rig is tied with a quick-release tension knot; the absence of blocks and fittings keeps things cheap and quiet, and tension is easy to achieve and adjust. I also use a tension knot as the parrel for the boom of my lugsail, allowing me to adjust the fore-and-aft position of the boom. A line tied off with a tension knot secures the mast in the partner, taking the place of a conventional mast gate.

SBM

SBMYou can guard against the slipped half hitch from shaking out by slipping a second bight into the first and pulling it tight. A pull on the bitter end will still release the hitch.

Tension knots tied with short lengths of line attached to the boat’s hanging knees hold the oars tightly under the side decks, where they’re out of the way but ready for instant access when needed. The ridge line I use to hang a tarp for a boat tent for sleeping aboard runs from the rudderhead around the mast, then back to a loop to finish with a tension knot. I also use quick-release tension knots on the lines holding the edges of the tarp to the side decks. For securing loose gear or bags, tension knots are often a better solution than bungee cords, which can’t be custom fit and can be difficult to secure under tension. In spite of their plastic-coated hooks, they can mar varnish and dent soft wood.

There are lots of other jobs aboard the boat and in camp that can be performed well with a bit of line, and almost nothing that can’t be secured and easily released with simple quick-release tension knots. Use the money you save on blocks and fittings to extend your cruising season instead.![]()

Tom Pamperin writes regularly for WoodenBoat. His first book, Jagular Goes Everywhere: (mis)Adventures in a $300 Sailboat, is available now at The WoodenBoat Store.

Note: The slip-knot loop of the trucker’s does come in handy when you use a line for a variety of purposes. The slip knot is easily undone with a tug on the line, but there is a a right way and a wrong way to tie it.

SBM

SBMThe wrong way to tie the slip knot for a trucker’s hitch. The bight must not be on the standing side (left here) of the loop. When trucker’s hitch is tensioned, the bight will shrink back into the loop.

SBM

SBMThe proper way to tie the slip knot is with the loop on the standing part of the line and the bight on the working side. Tied this way, the it will not collapse under tension in the trucker’s hitch.

You can share your tricks of the trade with other Small Boats Monthly readers by sending us an email.

Using a tension knot on a half pin is a easy way of giving you an instant releasing halyard, the Norwegian practice, or an instant release sheet, ( what I was taught as a doryman’s hitch. You need to lead the sheet or halyard around the pin, then tuck the loop in between the tensioned line and what ever bit of wood the pin goes through. What Ashley calls the slippery hitch #1619 or the slippery pin hitch #1620. On a small boat I like to use a recessed pin through a thwart so I can sit on it if needed, or a permanent pin cut off flush.

The Norwegians also use these tension knots on shrouds.

On my skiff with a mainsheet that leads from one quarter, through the clew then to a ring on the other quarter, I have a cut splice Ashley #2832, between the dead end of the sheet and the clew of the sail may be a foot or so above the dead end. The bight in the cut splice is sized so that I can tuck a loop of mainsheet into it. When tensioned the sheet holds the loop which can be yanked for quick release.

Tom, around 1995, I submitted to the International Guild of Knot Tyers, a knot that I used quite extensively in lieu of a Trucker’s Hitch. I called it a Z-Trucker’s Hitch and the main difference was that I used an Inline 8 instead of a full Figure 8 in the bight as you have shown. For me it was faster, repeatable and as you are using yours, quick to completely clear all bits of knots from a length of line. On the rare use that I have a need to tie and then loosen, then retie, I also use the full Figure 8 in the bight. Good article.

The Truckers hitch was originally the “Frigate hitch” long before there were trucks! It was used to secure deck cargo and barrels in the hold.

Good stuff-I’ve used a modified version that is easier to untie if hitch is subjected to a high load: after forming the initial bight and passing a loop through, simply pass the loop again-I’ve towed trucks using this approach and then easily untied the hitch.

Thanks for the comments and suggestions. There’s always another little trick to be learned with these kinds of knots, and everyone seems to find their own personal variants that work well for them. I really enjoy the minimalist, low-cost spirit of using lashings and knots instead of hardware where it’s convenient to do so. Some very old technology indeed.

I also use a variant of the trucker’s hitch; instead of going once around before putting the bight through the loop, I’ll do it two or more times – basically a figure 8, but only around the load side. I find the extra friction from the additional wraps makes untying an easier affair.