When I’m out sailing on the wide, cold waters of Puget Sound, I carry a lot of safety gear, but I’m more casual in my approach to kayaking for exercise on a slow-moving, shallow slough. A few weeks ago, I saw a couple of deadheads lurking just below the surface, and while I now steer clear of where they’re located, they got me thinking about the consequences of hitting something else hard enough to crack my kayak’s delicate mahogany hull. If the kayak took on water, it would be easy to get ashore and my safety would never be compromised, but getting back to the launch ramp overland wouldn’t be easy. I’d have a miles-long walk with a tote bag full of gear slung over one shoulder and my kayak over the other. I would spare myself a lot of misery if I could simply patch the hull and paddle back to the ramp.

Jennifer, my dental hygienist, in a one-sided conversation while a suction tube, a mirror, and an ultrasonic scaler were keeping me mum, mentioned that she carries Flex Tape aboard her sea kayak. It looked promising on the web, so I bought a roll. The label said it was for “boats and yachts, canoes and kayaks” and could be applied “wet or dry…even underwater, conforms to any shape or object,” and could seal “virtually everything.” I was, however, unpleasantly surprised the first time I tried to apply a piece of it to my kayak, which I had hosed down for the test. The tape stuck in some places but not in others and didn’t flex enough to stick to sharp inside corners. I did a bit more research and found a reference guide for Flex Tape on the manufacturer’s website. It stated that the tape is “not compatible with most paints”; to that, I’d add varnish. And then, hidden inside the roll of the tape, there was a warning I found nowhere else in the manufacturer’s literature: “Tape is not intended to remove cleanly. May damage surface during attempt to remove.” That was it for me and Flex Tape. I may give the rest of the roll to Jennifer because the tape will work on her plastic kayak.

Photographs by the author

Photographs by the authorWhile the packaging for Flex Tape makes wide-ranging claims about its abilities and applications, especially for marine uses, it didn’t take long to find out what it wasn’t able to do.

Decades ago, I’d heard that British kayakers were using Denso’s Densyl Tape for emergency leak repairs. It was manufactured in the U.K., primarily for industrial use to protect pipes from corrosion, and at that time wasn’t available in the U.S. The tape is now manufactured in Texas and available for DIY use in a 2″ × 33′ roll. Densyl Tape, according to the manufacturer, is “a cold-applied corrosion prevention and sealing tape based on a synthetic fabric, impregnated and coated with a neutral petrolatum compound.” The olive-drab petrolatum is only slightly sticky to the touch and has a texture somewhere between modeling clay and lip balm.

While Flex Tape’s rubberized backing is flexible, it does not do well with sharp inside corners or compound curves. This test patch adhered to the hull and skeg, but couldn’t adapt to the shape and seal the area.

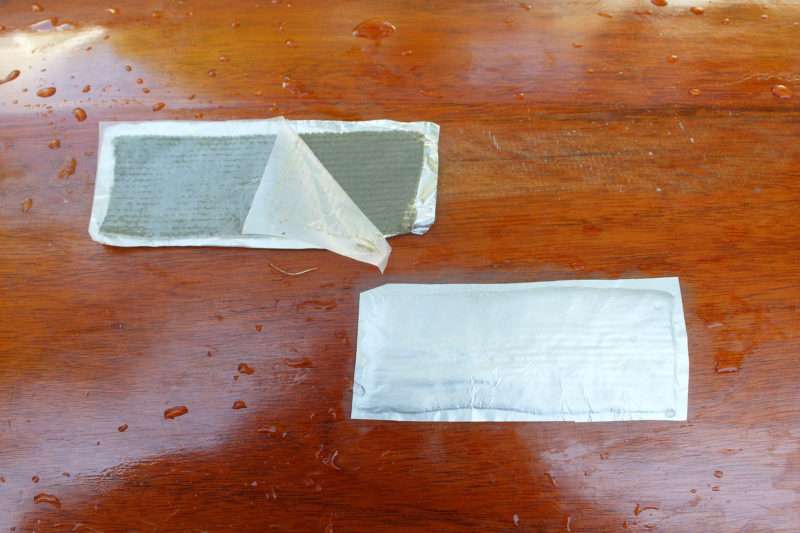

The full roll is about 5″ in diameter and much more than I’d need to carry for any outing so a few precut lengths would do. For testing, I cut 6″ pieces with scissors and, following the lead of U.K. Denso-advocates like sea-kayak instructor (and Denso-kit supplier) Howard Jeffs, I backed them with aluminum foil. The foil can stay with the tape when it is applied to a leak, preventing fingers from getting sticky with petrolatum. I put waxed paper on the other side and trimmed it and the foil around the tape with a margin of about ¼″. The prepared pieces take up very little space and would be easy to add to the minimal amount of gear I take for a two-hour paddle.

When the Flex Tape’s adhesive is able to bond to a surface, it has a tenacious grip and may need pliers to be removed.

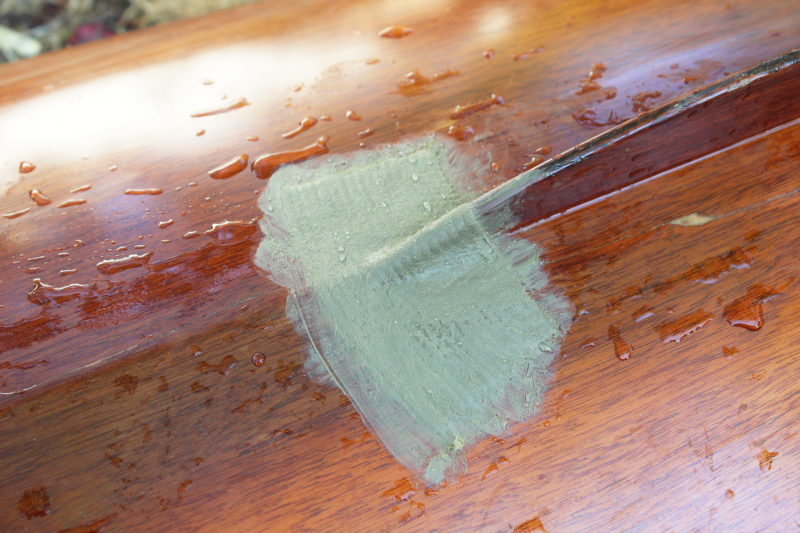

I wasn’t going to punch any holes in my kayak for the tests—it has already suffered enough after taking flight from the roof rack. Seeing how well it stuck to the hull was the important thing. After hosing down the hull, I applied one patch with the foil backing and one without it, both on the gentle curves amidships. Pressing the patch from the middle outward pushed trapped water out from under the tape. On the patch without the foil, I could see how smearing the petrolatum also forced a few beads of water through the tape but then consolidated the tape’s coating and the fabric to form a more impermeable barrier. Smeared petrolatum also created a fillet outside the fabric that seemed like it would facilitate the flow of water over the patch and prevent it from peeling. I applied a third piece of Denso, without foil, to the forward end of the skeg and it quickly conformed to the complex contour without creases or gaps.

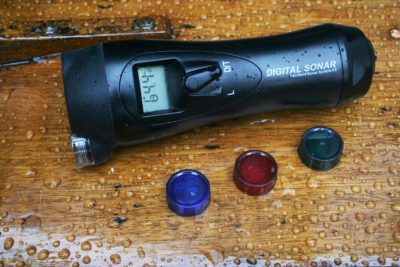

Denso’s Densyl Tape comes in a large, sticky roll. Developed as a means of preventing corrosion on metal pipes, it has been adopted by kayakers as an effective emergency patch.

With the patches in place, I paddled on a local lake for an hour, which is as long as it would take me to get back to the ramp on the slough in a worst-case scenario. All three patches stayed put and only the forward corners of the foil were dog-eared by the flow of water.

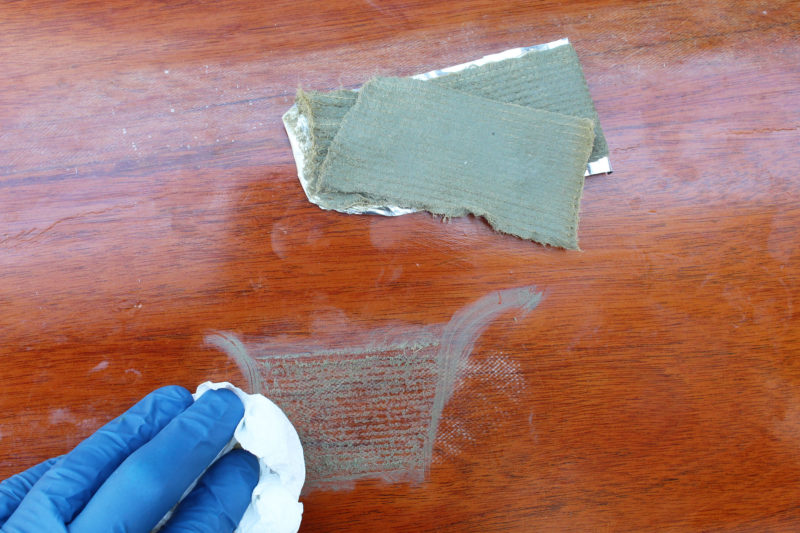

A strip of Densyl Tape can be applied right off the roll. Note how the tape’s coating feathers the edges. Gloves can keep hands clean but aren’t required.

One of the concerns I had about Densyl was for whatever residue it might leave behind after a patch is peeled off. If it were difficult to remove and perhaps contaminated the damaged area with petrolatum, it could make permanent repairs difficult. I needn’t have worried. What little goop was left behind was quickly removed with a paper towel and firm pressure. I finished up with soap and water just to make sure no oily film was left behind. The Densyl Tape I removed was as good as new and could be used again.

Strips of Densyl Tape can be sandwiched between aluminum foil and waxed paper to make ready-to-use patches. The foil backing can be left in place while the patch is pressed to the hull. It eliminates contact with the petrolatum and adds an extra measure of waterproofing to the patch.

Having the tape on the outside of the hull takes advantage of water pressure to stay in place. To see how it resisted water pressure working against the tape, I used a 4″ ABS drainpipe to hold a column of water and, for a leak, cut a 3″ kerf with a bandsaw.

Densyl Tape is exceptionally flexible and was easily applied to the complex shape at the forward end of the skeg.

Denso, without foil and applied over the kerf while water was flowing out of it, initially adhered to the pipe and stopped the leak. With 16″ of water in the pipe, the tape developed blisters that crept to the edge and then allowed water to flow. With 12″ of water, the Denso held its own against the pressure and didn’t form any blisters. None of my boats have hulls that draw even 12″, so a patch made on the inside could keep water leaking through a narrow crack. I would keep an eye on the patch and back it up to better secure it.

The three test patches on my kayak survived in very good shape after close to 5 miles, even with a few encounters with weeds like the one left draped over the stern.

The residue that Densyl tape leaves behind is easy to wipe off with a paper towel and firm pressure. The used tape can be re-covered with foil and waxed paper and reused.

Denso’s Densyl Tape is wonderful stuff: simple, effective, and well worth adding to any small-boat repair kit, and there’s enough on a roll to share it with boating friends.![]()

Christopher Cunningham is the editor of Small Boats.

Densyl Tape is manufactured by Denso. The company doesn’t appear to offer the tape directly. The 2″ × 33′ (50mm × 10m) roll is available from Amazon for $27.

Is there a product that might be useful for boatbuilding, cruising, or shore-side camping that you’d like us to review? Please email your suggestions.

Glad to see that this is available in the States now. I bought a roll years ago in the UK. It’s still good. Used to hack off pieces and put them into baggies to give to friends, students and colleagues back when I was guiding. One friend who had vacuum-sealing gear would use it for patch tape. This reminds me that I need to check and see if I still have a patch in my paddling gear.

I bet mineral spirits would be good for removing the petrolatum residue.

This photo from the Denso packaging shows the tape installed with the inside out. This is when used for wrapping pipes for corrosion protection. Is this the method you used for sealing leaks? Note this is for Denso tape not the Densyl tape. Not sure if there’s a difference.

Thanks for the review, helpful to know the disadvantages of Flex Tape.

There is no indication that one side of the tape differs from the other. The method of application in the illustration would direct users to have the reel of tape rolling around the pipe as it unwinds instead of rotating in the opposite direction, skidding against the pipe.

I would be curious to know how these two adhesive chemistries compare to Butyl tape and Silicon tape.

What is the difference between DENSO tape and PetroWrap Anti-Corrosion Tape … also sold on AMAZON?

I’ve used both in wrapping pipe. It is a petrolatum wax. It will adhere, very mildy to most shapes, but I would not put in any kind of adhesive category. It can be massaged seal well enough to keep water out at atmospheric pressures (gravity fed water).

We’ll use it in the merchant fleet to wrap hydraulic fittings after they’re hooked up. Absolute mess if you have a sloppy deckhand do it, but it’s awesome stuff. Never thought about it for small boats. Great idea!