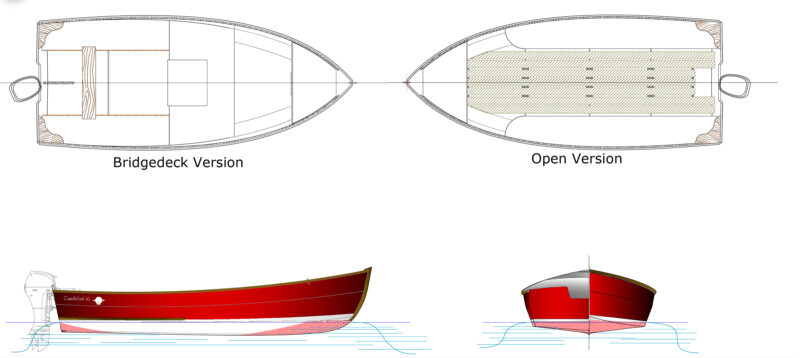

Sam Devlin’s Candlefish series—the 13, 16, and 18—was inspired by the pangas he saw while visiting Mexico. Those small workboats are sturdy but narrow, allowing them to weather rough water while still maintaining speed with a small motor. After the success of the cartoppable Candlefish 13—designed to be run with low-horsepower outboards—Sam recognized that people wanted more speed. He drew wide- and narrow-bodied versions of both the Candlefish 16 and the Candlefish 18. This “methodical uptick in sizes,” as Sam puts it, is commonplace for his design process. The narrow-bodied 16 was eventually discontinued, but the wide-bodied version has proved popular. Sam designed both a Bridge Deck Version with plenty of enclosed storage and a simpler Open Version. Drawings for both are included in the plans.

As with all of the designs from Devlin Designing Boat Builders, the Candlefish 16 is of stitch-and-glue construction. I was 12 years old in 2015 when my father and I decided to build a boat. To get a more complete boatbuilding experience, we opted not to purchase a kit, but instead to build the Candlefish 16 from the nine sheets of drawings included in the plans set. In addition, we used Devlin’s 80-page Building Instructions Booklet for Stitch & Glue Construction to guide our project.

Photographs courtesy of Lilja Hanson

Photographs courtesy of Lilja HansonLilja and her father began building their Candlefish 16 when she was 12. The stitch-and-glue construction was a good choice for introducing her to the art of boatbuilding and to the art of fixing errors—such as a chipped bottom panel at the stem—along the way.

We scarfed the okoume plywood to get the length required for the two bottom panels (each in two pieces) and the intermediate and sheer planks (each in three pieces) for the sides. The shapes for those pieces—cut from 3⁄8″ (9mm) plywood—and for the 1⁄2″ (12mm) bulkheads, decks, seats, knees and breasthooks, are given as drawings with offsets, while supporting diagrams show how to distribute the pieces on sheets of plywood. The plans illustrate mounting the four bulkheads and the transom onto a 2×6 backbone frame with vertical 2×4 supports and, for the transom, angled plywood braces.

The planks’ mating edges at the chines are given a double bevel, cut at 45 degrees both inboard and outboard, to ensure fair alignment. Then, holes are drilled and wire is used to stitch the planks and transom together. The seams are spot-glued with thickened epoxy from the inside, then the wires are removed, and the seams are sanded smooth and fair. The outer seams are taped with 17-oz biaxial tape. The hull exterior is sheathed in 5-oz Dynel cloth and epoxy before being turned right-side up; friends and family made light work of flipping the hull. Once turned, the inside of the seams could be reached, and we gave these fillets of epoxy and wood flour, 17-oz biaxial tape, and a layer of 6-oz fiberglass cloth.

We had opted for the more complex interior appointments of the bridge-deck version for the storage compartments it offered and had built the hull around the plan’s bulkheads for it. We installed the 1⁄2″ (12mm) side benches, the bridge deck, and two storage lockers, one forward and one amidships.

the Candlefish 16, trailer, and 20-hp outboard motor together weigh in at around 1,500 lbs making it the ideal boat for towing behind the average family car.

The plans specify 3⁄4″ × 1 1⁄2″ hardwood for the inwales and outwales. To bend the pieces without the use of steam, we glue-laminated their forward halves from two 3⁄8″-thick pieces of white-oak to accommodate the curve of the sheer plank at the bow. Similarly, the plans suggest horizontal kerfs in the forward end of the 3⁄4″ × 1″ keel to accommodate the bend at the forefoot.

The Candlefish 16 webpage notes that the boat can be built in about 200 hours. Our father-daughter project took 18 months of sporadic work alongside school, extracurriculars, and work. I was 14 by the time the painting was finished, and our boat was ready to launch. We bought a 20-hp long-shaft, four-stroke outboard for the boat, which is in the middle of the recommended range of 10 to 30 hp.

The storage lockers in the bridge-deck version of the Candlefish 16 offer an impressive amount of space. The bow locker is ideal for stowing anchors and docking lines, fenders and extra flotation, while the ’midship locker has room for lifejackets, cushions, coolers, and more.

The Candlefish 16 is very light for its size. I have never weighed mine, but online forums suggest that the dry-hull weight falls around 325 lbs. Add to that the 20-hp outboard and a trailer Dad salvaged from the side of the road, and the whole package is well under 1,500 lbs and easily trailerable by any car with even modest trailering capabilities.

There are two storage lockers: a smaller one under the foredeck and a larger one under the bridge deck. The smaller locker stores fenders, deck lines, two small anchors and their rodes, and foam for flotation. The larger storage area amidships can hold PFDs, flares, coolers, gear, and a storage box for smaller pieces of equipment, with room to spare for at least four totes of gear. With its hatch closed, the larger storage compartment serves as a bench. A starting battery, a 3-gallon gas tank, and more flotation foam fit under the aft end of the side benches, out of the way but easily accessible. For flotation, the plans call for inexpensive Type-II PFDs strapped under the seats. We found billets of flotation foam washed up on the beach and they do just fine.

The cockpit is easily hosed down and has limber holes in all but the forward bulkhead and a drain plug in the transom. I have found that the limber hole in the aftmost bulkhead, at about 1″ in diameter, provides for adequate and efficient drainage, but anything less than 1″ can easily clog. The drainage under the bridge deck is facilitated by a 1″ PVC conduit ’glassed to the inside of the hull between that compartment’s bulkheads.

For our family, the Candlefish 16 is the perfect little on-water pickup truck. The boat handles well in rough water, though in choppy conditions we all prefer to wear rain gear as it can get fairly wet. When we beach the boat, the keel and the runners, which we chose to add aft just a few inches inboard of the chines, are protected by a stainless-steel half oval. Rolling on fenders up and down beaches is very doable and was easy for me even at age 14. The same goes for docking and loading onto the trailer, as the boat can turn within its own length and is sensitive to any changes in speed with the 20-hp outboard.

With just Lilja on board, the Candlefish 16 tracks and trims well.

The Candlefish 16 handily carries my family of four, plus the dog, and in calm conditions can take a few additional passengers. We take the boat camping with all of us aboard along with a cooler, camping gear, and even a paddleboard or sit-on kayak strapped along one of the inwales. While that may be a tight fit, it certainly leaves plenty of freeboard remaining for open-water crossings.

With our 20-hp outboard, the Candlefish will get on plane with two people aboard, but with more weight it’s hard to get past a semi-plane. The boat moves fine at that point, but while it isn’t plowing or displacing too much water, the plane isn’t as clear and the bow doesn’t carve the water as cleanly. I wouldn’t advise going with an outboard of less power than 20 hp. The plans suggest a maximum of 30 hp, which I would be eager to try out, especially for a larger crew.

The deep cockpit and ample seating arrangements mean that the Candelfish 16 can easily accommodate a family of four, plus dog and camping gear, in most weather.

I can’t think of a better outboard skiff for an amateur or adolescent boatbuilder. The uncomplicated nature of stitch-and-glue design and the options given between open and bridge-deck versions make for the perfect balance between straightforward construction and personal customization. What’s more, the robust seaworthiness of the Candlefish 16 is well suited to exploring the Maine coast, messing around with friends on lakes, and providing simple transport anywhere you want to have an adventure. The ample storage is conducive to overnight exploration, and the size of the boat is manageable while still allowing for a group of friends or family to come aboard. Now 20 years old, I’ve had great fun using my Candlefish 16 for several years and look forward to many more.![]()

Lilja Hanson is a student at Barnard College of Columbia University studying English. She grew up on and around boats in Downeast Maine and has combined her passions for writing and boats as WoodenBoat’s editorial intern this summer.

Candlefish 16 Particulars

Length: 16′ 2 1⁄2″

Beam: 6′ 10″

Draft: 7 1⁄2″

Propulsion: 30-hp outboard, max

Plans for the Candlefish 16 are available from Devlin Designing Boat Builders for $95 (download) or $125 (printed). The WoodenBoat Store offers the plans for $85, digital or print (plus shipping).

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats readers would enjoy? Please email us!

Well done, Lilja. I’m sitting on my Candlefish 16 plans from Sam Devlin for 3 years now.

I am thinking it is time to bite the bullet on purchasing the marine plywood. I had a bit of sticker shock over last two years and it doesn’t seem as if the prices will head back down anytime soon.

You answered my question on the size outboard to use. I plan to keep the tiller model but hesitate to get too large a motor, being as I need to consider my own weight in the stern of a 345-lb boat.

Bravo, Lilja, and well done bringing your dad along for the boatbuilding ride.

Wayne Poulsen

Fremantle

Western Australia

Nice job!

A very good write up. I have a kit in storage and as I am in process to moving to the coast area Sequim of Washington, I will be constructing as soon as my work space is organized. I may add a few inches around the top to keep her even more dry as I will now be using in the ocean.

Getting the boat to plane is a problem of weak, heavy 4 (jokes). 2-strokes in good condition are available used in very good reliable condition and parts are available if necessary. 2-stroke outboards were designed to be light, powerful and get on plane fast. Boats that are slow like 4 jokes, use less fuel,

Hey, how about a cuddy cabin, sitting headroom doghouse on the 18 footer?

Very nice ,very professionally done article, BTW.