A little learning is a dangerous thing

That’s according to a poem Alexander Pope wrote more than 300 years before Dennis Ward of Riviera Beach, Florida, figured it out for himself. Reading a book on stitch-and-glue boatbuilding inspired him to design and build a boat in 2004 even though he had no experience with either skill.

Fired at first sight with what the Muse imparts,

In fearless youth we tempt the heights of Arts

Dennis’s muse was Sam Devlin and his temptation was the boatbuilding method detailed in Sam’s book, Devlin’s Boat Building. After reading the book, Dennis went straight to work to create a boat of his own: “I sketched a dinghy on paper, then glued some pieces of wood together with epoxy, and was amazed I had made a boat that didn’t sink.” Cutting out pieces of plywood, drilling a bunch of holes, and wiring and gluing the pieces together just happens to be the easy part, but the goal is more than just keeping the water out. Dennis quickly discovered that the dinghy was unsafe on the water. Pope expressed that awakening of a novice to what has yet to be learned:

But, more advanced, behold with strange surprise

New distant scenes of endless science rise!

The subtitle of Devlin’s Boat Building is “How to build any boat the stitch-and-glue way”. Sam likely intended “any boat” to encompass the sizes and types the system works for—he has designed and built boats ranging from a 6′3″ dinghy to a 45′ motor cruiser—but “any boat” could also be taken to mean good boats as well as bad boats. Sam’s boats, the result of a wealth of education and experience in boat design and construction, belong in the former category. Dennis admitted that his boat had fallen into the latter: “That dinghy has since become yard art.” The lesson he learned was “Let the professionals design the boat!”

Photographs by and courtesy of Dennis Ward

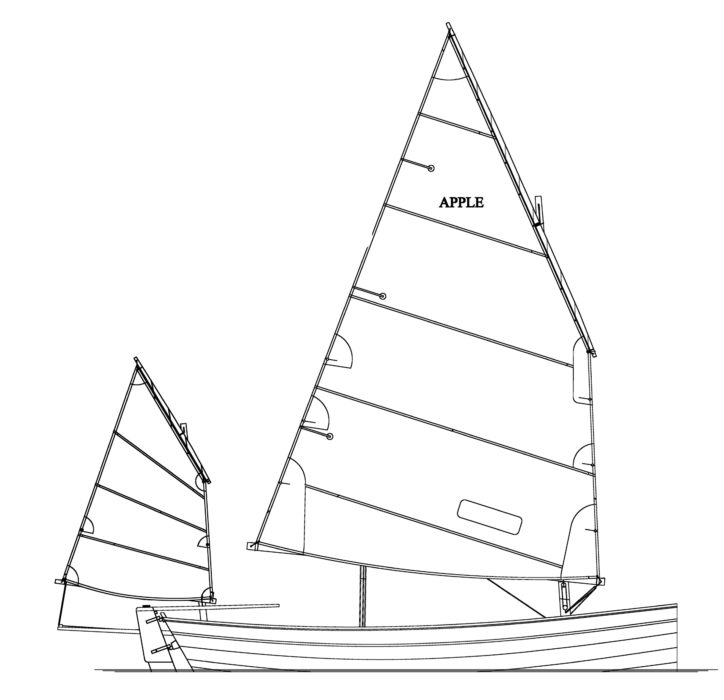

Photographs by and courtesy of Dennis WardIn October of 2021, Dennis retired after a 35-year career as a Palm Beach County ocean lifeguard, rower, rescue-boat driver at Jupiter Inlet, Boynton Inlet, and Boca Raton Inlet. A couple weeks later, he got all six of his boats in the water for some photos. At the water’s edge, from left: Dennis’s self-designed dinghy, kid’s rowboat from a thrift store, Passagemaker Dinghy, Gloucester Gull, and Ben Garvey. The Gloucester Rocker is safely away from the water. His Chester Yawl isn’t shown.

Despite the disappointing results of his first efforts, Dennis thoroughly enjoyed the time he spent building the dinghy. For his second boat, he skipped the designing and bought a kit for Chesapeake Light Craft’s 11′ 7″ take-apart Passagemaker Dinghy. He finished it in 2007 and, although it had all the characteristics that would put it in the “good boat” category, the Passagemaker was only afloat a few times before Dennis was back in his back yard under a 10′ by 20′ canopy, “making more sawdust.” His series continued with a Gloucester Gull and a partially built child’s rowboat he bought in a thrift store for $30. The Gull was afloat only a few times, and the little rowboat has yet to be launched and is waiting for an interested kid he can give it to.

The mild weather in Florida made it practical for Dennis to build the garvey outdoors under a canopy.

One of Dennis’s friends bought plans for Doug Hylan’s Ben Garvey, decided the project was more than he could manage, and gave the plans to Dennis, who started building it in 2011. After he had finished the hull and flipped it right-side up to begin work on the accommodations, he decided to do away with the center thwart. “That way I wouldn’t be stepping over it, and there’d be 8′ of space on the bottom for horizontal activities, like napping.”

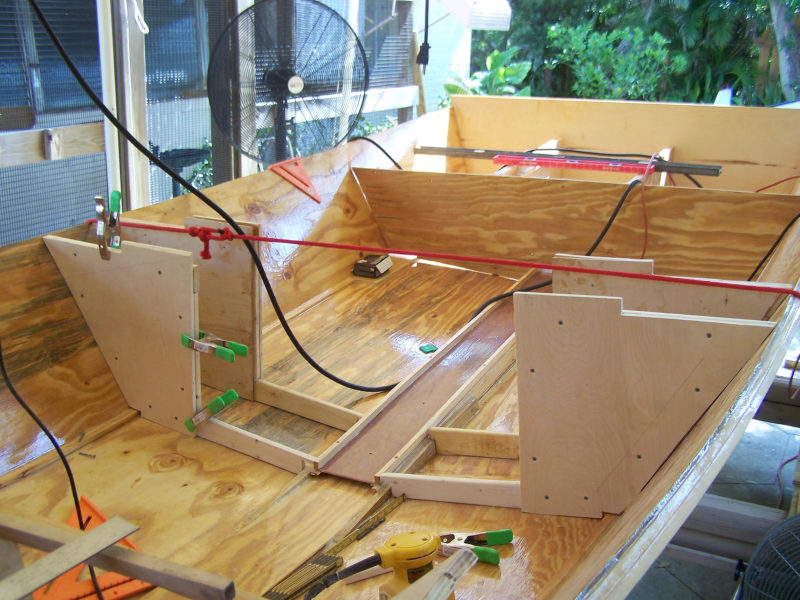

Having decided to omit the center thwart to open up the center, Dennis devised a structure that provided a walk-through passage between partial side benches and framing across the bottom.

A cockpit sole over the added interior framing provides a smooth surface for napping and enclosed spaces for flotation.

Concerned about losing the strength the thwart would have provided to the hull, he replaced it with two enclosed storage-compartment seats on either side. “I also intended to add several more frames on the bottom to add more strength to the chines and sides. The extra frames would be a tripping hazard and make napping uncomfortable; adding a cockpit sole on top of the frames seemed to be the ideal solution. I ended up with a double-hulled boat with flotation in between.”

The gunwales are teak and were initially varnished but Dennis decided “it’s like lipstick on a pig. This is basically a workboat, not a fancy piece of furniture.” He also embedded tie-dyed fabric on a pane forward and a hatch aft “because I wanted to learn how to do that. What I didn’t know at the time is that I coulda bought clear epoxy, instead of regular yellowish epoxy. So the tie-dyed bright whites turned yellow.”

Dennis finished building the garvey in 2012 but then left it on sawhorses under a canopy for several years until he could afford a trailer. A few more years drifted by as he saved enough for a 25-hp outboard for it.

Dennis worried that his weight in the stern along with that of the motor and fuel tank would cause the bow to rise too high, but It sat in the water perfectly.

While the garvey waited, Dennis’s mother gave him the plans for the Gloucester Rocker as a Christmas present. That was in 2017, and all through the following year he worked on it without telling her. The hull and rockers were straightforward work but the seat and grab bar—fashioned from walnut and holly that he had harvested on his mother’s lot—were not. The curved and beveled joints were not easy to get right and by the time he got perfect fits, the two pieces had taken more time than the rest of the boat. The next Christmas he surprised his mother with the rocker; she was delighted with it and she uses it to hold her dog’s toys.

Rob Rogerson

Rob RogersonOn the boat’s first sea trial, Dennis was “somewhat surprised how powerful the 25hp motor was. The garvey is a heavy boat but it got up on plane right away and I wasn’t comfortable going any faster than half throttle. An hour later, the garvey was back under the canopy.”

The garvey was finally ready to launch in 2020, but it wasn’t launched until this year for what Dennis says are “various lame reasons. Mostly, I’d rather build boats than go boating.”

Dennis’s 15′ Chester Yawl kit boat is being built with the help of his 86-year-old mother. She offered her basement for the project.

And he has been building boats. A Chester Yawl is in the works in his mother’s basement in North Carolina. Earlier this year, Dennis built the molds and a ladder frame for the L. Francis Herreshoff pram featured in John Gardner’s Building Classic Small Craft. The hull of the 10-footer is usually built in lapstrake cedar on steam-bent white-oak frames, but Dennis had been given a generous assortment of sapele strips and was eager to turn them into a boat.

In fearless youth we tempt the heights of Arts

Strip-building would be uncharted waters for him and, more cautious now after the experience of his first dinghy, he floated the idea of strip-planking the pram on the WoodenBoat Forum. He was dissuaded from making an attempt that could waste time, money, and valuable wood.

New distant scenes of endless science rise!

Rather than forge ahead, he bought Nick Schade’s book, Building Strip-Planked Boats. “I’ll read up some more before I decide what to do.”

Dennis is happier building boats than using them: “The prominent pleasure of wooden boats is in all the different things I learn in the building process.”

Do you have a boat with an interesting story? Please email us. We’d like to hear about it and share it with other Small Boats Magazine readers.