Tom Gruitt

Tom GruittThe International Fireball is a development class of racing sailboats that allows builders to incorporate new technology and a variety of rigging options (such as the trapeze shown in use), enabling sailors to stretch the limits of their abilities.

The International Fireball and its friendly network of members have earned the class a reputation for being competitive—but without losing its sense of fun. This two-man high-performance racing sloop (16′ 2″ LOA, 4′ 6″ beam) excels in wind conditions of 15–20 mph, conditions that make some other small-boat classes take shelter.

In 1962, Peter Milne designed the International Fireball to be an exciting and responsive one-design that could be built by an amateur woodworker. In this age of high-cost building composites, the Fireball remains one of the few high-performance one-designs that allow the builder to construct a hull from scratch using wood (prefabricated fiberglass hulls are also available). Over 15,000 boats and 50 years later, the class is everything the designer could have hoped for.

While the Fireball is still technically a one-design (a sailboat class that requires all boats to be built to the same specifications, with a few variables), some factions of it have also evolved into a development class (a class that allows the incorporation of some technical advancements). The design can take advantage of updated building and rigging adaptations, such as laminate sails and adjustable, bendable masts that give greater control of the rig while underway.

This boat is not well suited to the beginning sailor but appeals to racers and non-racers alike; anyone interested in the sheer fun of sailing a fast sailboat will love the Fireball. There are many husband-wife, boyfriend-girlfriend, parent-child, and sibling teams sailing the type. Almost all levels of competition, from the local club venue to international events hosted at exotic locations around the world, are available to racers. Many Fireballers who have explored other designs have returned to the Fireball with renewed interest, rekindling friendships and mentoring younger members.

Tom Gruitt

Tom GruittFather-and-son team, Duncan and Graham Schaefer built their boat and enjoy racing together. Their home port is Chardon, Ohio, but since the boat is easy to haul on a lightweight trailer or by cartop, they can race anywhere within driving distance.

The sail plan is large enough to drive the hull in light winds yet small enough that the average size crew of two men, approximately 165 lbs each, can hold the boat upright by hiking out on the trapeze in a stiff wind. (A trapeze is a wire that runs from the masthead that enables a crew member to extend his body out from the hull to provide outboard ballast.)

The hull is held to a minimum weight of 175 lbs and has a combined sail area between main and jib of 123 sq ft. It can easily plane upwind in 15–20-mph winds. When the boat rounds the weather mark and heads off on a beam reach, and the crew hoists the 140-sq-ft spinnaker, the Fireball can make 20 knots or more. But the original design had a problem with the boat burying its bow in these conditions.

During the 1980s a group of inventive builders began to experiment with the non-measured sections of the forward area of the hull to solve this problem. They found that by adding more volume to the forward sections, the resulting hull could be handled more aggressively in moderate wind and waves. Working within stated tolerances allowed by the class rules at the time, they developed a boat with less rocker (the fore-and-aft sweep of the boat’s bottom) and added a set of bilge panels that would enable the boat to plane sooner and in lighter winds. This modified design provided a clear advantage over the standard design Fireballs that were being built up to that point. This altered configuration became known as the wide-bow design. Although the class association will not change the original design to reflect these alterations, it does allow the wide-bow design to compete in regattas, as long as the hull passes the standard measurer’s exam for certification as an International Fireball, as outlined in the rulebook.

Building the International Fireball

From 1998 through 2006, I oversaw a boatbuilding program in my woodshop classes at Jefferson-Morgan High School in southwestern Pennsylvania. We built Fireballs during the school year and then learned how to sail and race them against other schools with similar programs. During that time, we worked closely with Fireball International and the Winder Boat Company in England, considered by many to be the ultimate builders of the wide-bow Fireball. They shared some key measurements that enabled us to build a wide-bow Fireball that resembled their hulls. We discovered that many of their altered measurements pushed tolerances to the outermost bounds of the class rules.

After discussion with Fireball International’s secretary about possible problems that might occur by pushing measurements to the edge, we decided to institute a 5mm rule to our building process. Simply stated, we would not exceed 5mm where 8mm of tolerance was allowed. Were we to push measurements to their maximum tolerances, we would not leave any room for error; even sanding and finishing the completed hull could cause a variance of as much as a few millimeters. Because the altered dimensions left so little room for error, we built a male construction form—an idea that came to us from the chairman of Fireball International’s technical committee.

David White

David WhiteStudents in David White’s shop class build the wide-bow Fireball on a setup of male molds, which help the builders remain faithful to the hull’s intended shape.

The male form holds the hull in a rigid state, giving better control during construction and ultimately providing uniformity among hulls. The form took the better part of a school year to design and build, but when we pulled our first hull off it we realized that it had taken less time than previous builds had, so we think the extra effort was worthwhile. We designed the form to be easily assembled and disassembled, as we sometimes lend out the form to like-minded programs and schools.

When we built our second hull, we gained a greater appreciation for the form’s stability. We were able to pre-measure all areas of the hull before its permanent assembly. The finished hull passed a measurer’s exam, even though we had decided to alter the dimensions of the lumber we used to keep her weight down, using 4mm-thick plywood for the bow plate and transom instead of the 15mm solid lumber as called for in the plans.

We also used a ’glass-taping method of construction between the bottom and sides to eliminate chine logs. Epoxy fillets replaced support pieces of solid lumber that were to outline the bulkheads and tank sides. The finished hull weighed 150 lbs before fittings. We documented everything and completed a set of building instructions based on our research. Our instructions cover the essential steps in building the male form and explain the ’glass-tape construction method we used to build our hulls.

Being a development class, the Fireball offers racers a wide array of rigging options. The Fireball association regularly reviews and revises their rules, allowing the class to evolve with changes in building technology and advancements in rigging, such as the introduction of spinnakers and trapezes. The Fireball became an international class in 1970 and, as a result, the hulls became more uniform due to tightened tolerances of measurements.

Tom Gruitt

Tom GruittWith 15,000 or more boats in existence, International Fireball regattas around the world draw great crowds of friendly yet competitive racers.

If you’re hoping for a high-performance sailing dinghy that offers great competition at all levels of racing, backed by a friendly social group, then the Fireball may be the boat you’re looking for. If, in addition to that, you want to build your own boat and have the satisfaction of racing something that you created, the Fireball is definitely the boat for you.![]()

Plans for the Fireball are available from the International Fireball Association, [email protected], or the Canadian Fireball Association, [email protected]. For David’s instruction booklet, contact [email protected].

Canadian Fireball Association

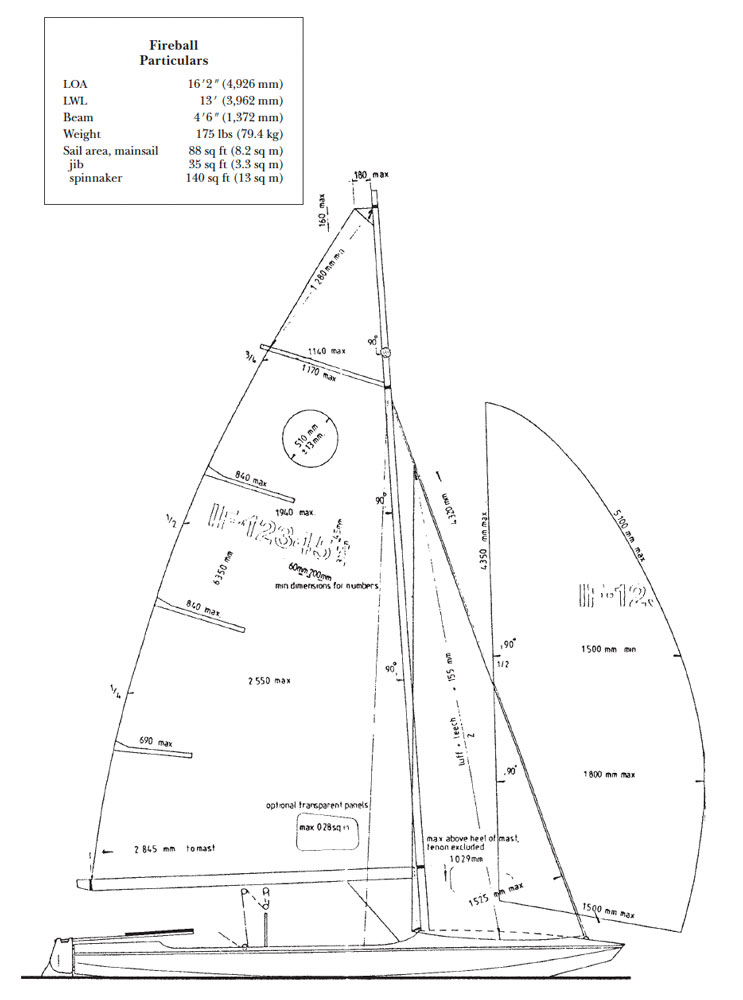

Canadian Fireball AssociationThe International Fireball’s sail plan, with its 123 square feet of measured sail area promises very lively performance for the 175-lb hull. The full-length top batten was ahead of its time when this boat was designed nearly 50 years ago. Within the dimensional limits shown, the sailmaker is free to experiment.

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.