With our small armada of boats, kayaks and a canoe, we have quite a selection of synthetic fabric, webbing, and line that needs to be cut. Many of the synthetic fabrics used for boating and camping will unravel if the ends are not sealed as they are cut or afterward. In the past, we used the open flame of a pocket lighter to sear the ends of the various materials to keep them from fraying, but when we needed to neatly cut several strips of nylon webbing for a boat cover we decided to try the Edge Hotknife sold by Sailrite.

Kent and Audrey Lewis

Kent and Audrey LewisThe Edge Hotknife will reach its maximum temperature of 752 degrees Fahrenheit within 6 seconds of pressing the trigger.

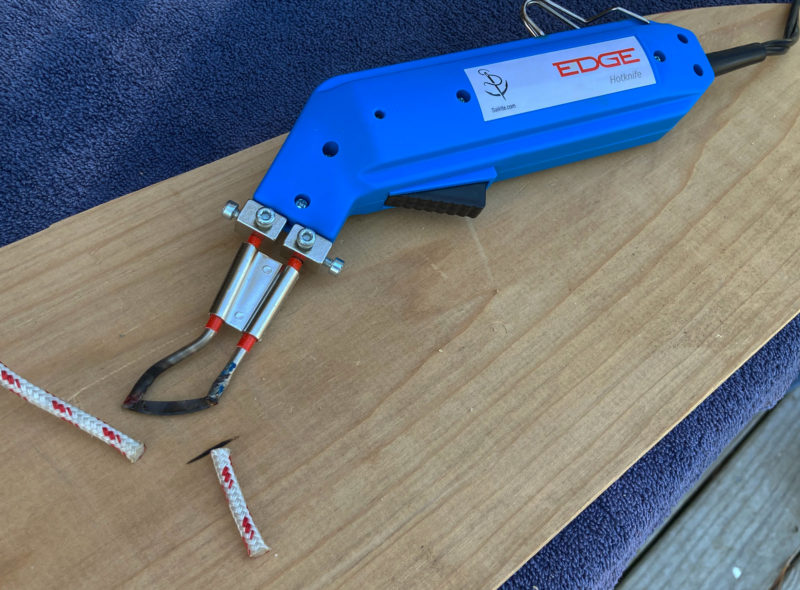

We purchased the 110-volt Edge Hotknife in a package that included the R blade, cutting foot, wire brush, hex key, and a carrying case. The Hotknife itself weighs 2 lbs and has a nice 9-1/2″ power cord that reaches a lot of spots in the shop. The Hotknife is also available in a 220—240V version and an 18V cordless version powered by a rechargeable lithium-ion battery. The Sailrite website notes that the 110V model also works well with inverters, as it draws no more than 60 watts. That makes it useful aboard a boat with an electrical system. Our Jackery 160 portable power station, with its built-in inverter, also provided the power the Hotknife needed.

With a pull of the trigger, the blade heats up to 752° F in four to six seconds, and at that temperature a lot of material can be cut in a short period of time. The cutting blade is only heated when the trigger is pulled, so you can avoid producing an open flame or drips from overheating the material. The trigger should not be continuously held on while cutting; it can be manipulated on and off as needed to keep the blade heated to the appropriate temperature, as a red-hot blade is too hot. The instructions suggest 15 seconds on, then 3 seconds off.

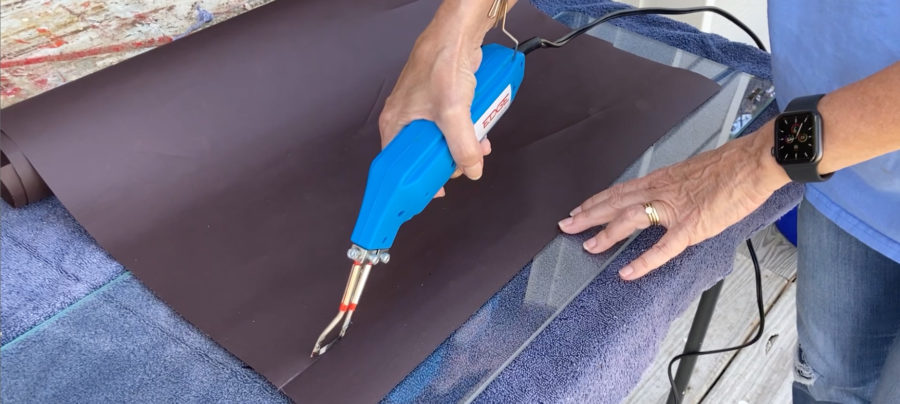

We’ve used flashing, Formica, and even scrap wood for cutting surfaces and recently purchased Sailrite’s tempered cutting glass to use with the Hotknife. The glass has the advantage of not scorching and creating smoke. The R blade is the primary knife blade and its curved edge cuts both straight lines and curves. There is a cutting foot that can be used with the R blade that raises the material and the knife above the work surface below, allowing materials to be cut on regular surfaces without damaging them. The R blade can also be set just below the bottom of the cutting foot so the foot will hold material down and prevent the cut edges curling. The blade can then create a clean sealed edge and fewer black blobs or sharp points on the ends of synthetic materials.

The Edge Hotknife makes clean, quick work of cutting and sealing the edges of webbing, line, tape, fabric, and sailcloth. We have been pleased with the results and consider it far superior, much safer, more accurate, and easier to use than our low-tech lighters. We save a lot of time using it and get nice, repeatable results. It makes cutting synthetic materials an enjoyable experience.![]()

Audrey and Kent Lewis mess about in small boats in the shoal waters of Northwest Florida, and chronicle their adventures at their blog, Small Boat Restoration.

Sailrite sells the 110-volt Edge Hotknife Package for $139.95. Other Hotknife models and accessories are available from Sailrite.

Editor’s Notes

I’ve been getting by without a hot knife since I started making my own camping gear back in 1970. For lightweight nylon fabrics, I sharpened the tips of soldering irons I used for electrical work. They weren’t at all suitable for thick fabrics like Sunbrella or for cordage. After reading the Lewis’ review, I wanted to see what else was on the market and found a few hot knives that were quite similar. I bought the Electric Hot Knife/Fabric & Rope Cutter by RoMech.

Christopher Cunningham

Christopher CunninghamThe RoMech hot knife performs well on synthetic webbing, rope, and fabric.

Like the Edge tool, the RoMech’s tip temperature is regulated by holding the trigger on for 15 seconds and releasing it for 3 seconds. I’ve using plywood, aluminum, and glass as cutting surfaces. Plywood works fairly well, though the hot blade sinks into the wood, making it hard to turn the blade to cut curves. On the aluminum, it’s best to pull the tool because the blade doesn’t slide across the metal when pushed. This makes it hard to follow fabric edges. Glass is by far the best surface for cutting. There’s virtually no friction, so the blade moves smoothly when pushed, making it easier to follow a line. The blade isn’t channeled in the glass so curves are effortless. I’ve only used single-strength window glass, the only piece I have, and the hot blade hasn’t cracked it yet.

The RoMech ($69 on Amazon) is listed as no longer available. An identical tool is available from Rongte ($65). A tool identical to the Edge is offered by DeVandy ($79).

Afterword

The RoMech hot knife I bought is made in China; I presume the identical Rongte is too. Sailrite’s Edge is also manufactured in China; and I would also presume the identical DeVandy is too. Author Kent Lewis checked with a Sailrite representative about the Edge and received this in reply:

“The Edge Hotknife is made in China. We were not able to find someone willing/with the capabilities to make it for us stateside, so were forced to source it. There are a lot of look-alikes but I can assure you ours is internally different. We wanted to design it in such a way that it would be possible to use it in a production environment.”

Ed.

Is there a product that might be useful for boatbuilding, cruising, or shore-side camping that you’d like us to review? Please email your suggestions.

These are really useful making neat cuts in kayak-covering material. I picked up a really inexpensive one at Harbor Freight. A simple blade for cutting rope in a soldering gun lives in my home shop rigging bag and gets a lot of use.

This sounds good. I have a short blade for use with my Weller pistol soldering iron. Are any of these units UL approved?

None of the four hot knives mentioned carry the UL (Underwriters Laboratories) mark, certifying independent testing. The all bear the CE (Conformité Européenne) mark, indicating a manufacturer-certified compliance with European standards. There exists a similar CE mark, with the two letters closer together—the ends of the C even with the far-left side of the rounded E—that stands for China Export, which is used, without regulation, by Chinese companies taking advantage of its similarity to the European mark. None of the hot knives appear to have the Chinese Export mark.

I’m not sure why you would worry about a UL listing. It’s not like you would be leaving it unattended. I used to work for the UW – Center for Limnology where I bought one of the Sail Rite models for use in the shop. I have used it for cutting everything from nets to heavy duty tarps and line. Basically it will cut anything that’s synthetic. I really liked the foot for cutting flat material. It can actually be used on fabric that is not on a table. It was money well spent.

After reading this article I bought an Amazon version for $65 – fabulous. I’m building a SOF Whitehall and the hot knife does a great job of giving a nice, even cut. I never leave it unattended and don’t need to, since it heats so fast.

A worthwhile $65.