I’ve built five boats, and all were truly rewarding projects. The first was an 8′ pram that I built to my own plans in about a week. Having done a lot of carpentry, I knew how to use woodworking tools, but I really didn’t have a clue about boatbuilding. The second and third boats were skiffs, an 8-footer and a 12-footer, and I paid more attention to detail as I refined my skills. I built the fourth boat, a cedar-strip Rangeley 15, from a Newfound Woodworks kit, and my latest build is another kit from the same company: the 16′ 2″ Adirondack Guideboat, based on a design by Warren Cole.

Adirondack guideboats were designed and built beginning in the 1840s for guides to take their wealthy clients fishing in the lakes and streams of New York state’s Adirondack Mountains. Guides rowed these boats from the forward seat while the client sat in the stern and cast a fly rod.

Sarah Vincenzo

Sarah VincenzoOne of the benefits of strip-plank construction is the uncluttered interior. I chose to buy the optional cane seats from Newfound Woodworks; the seats add that final touch of old-world class to the boat.

After building boats from plans, where I had to find sources for all the materials, I concluded that building from a kit (especially one from Newfound Woodworks) was the way to go. The kit came with almost everything I would need to build the boat. It included all the wood, the molds, epoxy, fiberglass, varnish, brushes, rollers, plastic trowels, hardware, and even latex gloves. The only items I had to purchase were sandpaper and vinegar (for epoxy cleanup). When I had built my Newfound Woodworks Rangely 15, I had ordered a pre-kit, which includes a book and DVD about building cedar-strip boats as well as a DVD on fiberglassing, and these I had hung on to. They are very informative, and I would recommend them to any first-time strip-plank builder. And, whenever I had questions that I couldn’t answer with the instructional materials on hand, Alan and Rose of Newfound Woodworks were extremely responsive.

The cove-and-bead cedar strips and wood for the gunwales arrived in a crate about 10″ × 12″ × 16′, which doubles as a strongback to support the molds.

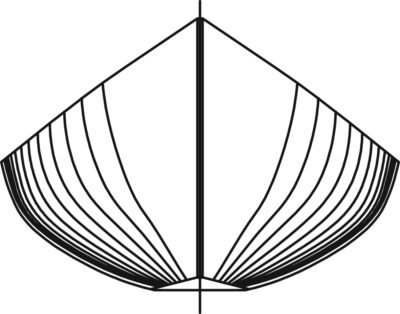

The building process is straightforward and begins with making two sets of legs to hold and level the strongback. The molds are fastened perpendicular to the strongback, and then cedar-stripping the hull can begin. The strips, with Titebond III glue applied to the edges, can be either stapled or clamped together. The forms are made with a groove paralleling the perimeter of the mold for clamping if that is your choice. While there are some who find the staple holes unattractive, I preferred the staple approach because I could staple and glue as many rows as I liked without having to take the time to apply the clamps and wait for the glue to dry before removing them.

Abby Fiske

Abby FiskeAlthough the Guideboat is designed to be rowed, I can paddle it canoe-style and it performs well.

The stripping process continued until the forms were covered. Then I had to pull the nearly 1,000 staples. I found that an old-fashioned nail-pulling/end-cutting tool is perfect for the job. As it grabs the staple and then rolls it out there is little or no gouging of the wood. With all the staples removed, I could pop the boat off the frames and start sanding and smoothing the hull prior to coating with epoxy, and then fiberglass and epoxy.

Once you have finished the fiberglassing and applied many coats of varnish, you are ready to flip the hull right-side up and start the same process on the interior before fitting the gunwales, decks, and seats. I estimate that I spent 300 to 350 hours over five months from start to finish on the build.

The Guideboat weighs only 65 to 70 lbs and is easy for me, at 76 years old, to load on the rack and tailgate of my pickup truck. It is designed with three seats: a bow seat, a stern seat with backrest, and a ’midship seat. All three and the backrest (purchased as an optional set) are caned, as many of the seats in the early Adirondack boats were—very comfortable, and attractive.

Abby Fiske

Abby FiskeThe cedar strips from Newfound Woodworks ranged in color from light gold to dark mahogany. I made the most of the variety to create symmetrical patterning in the hull, which I knew I would leave bright-finished. I bought standard 8′ oars but would recommend 7′. The Guideboat rows smoothly, feels stable, and I can comfortably maintain a 4-mph pace.

I used the formula from Shaw and Tenney to determine the length of the oars from the span of the ’midship oarlocks. It called for 7′ 8″ oars. Since I often overlap oar handles while rowing, I bought 8′ stock oars. After rowing the Guideboat with them several times I would recommend going with 7′ oars.

Designed as a boat used for fishing with the guide doing most of the work, it is very stable. To me it feels as stable as or better than a wide, general-purpose canoe. Although designed for two, it can easily carry three people. It rows beautifully, tracks well, is easy to turn, and I can comfortably maintain 4 mph. I have not had it out in choppy conditions, but it does handle well in a light to moderate breeze.

Robert Conkey

Robert ConkeyThis is how the original guideboats would have been used: the guide rowing from the bow seat while the client sat in the stern. The cane backrest in the stern provides the passenger with an added measure of comfort.

While the Guideboat is meant to be rowed, it is also well suited to paddling like a canoe, either solo from the middle thwart or tandem from the end thwarts. It’s a good way to explore narrow waterways when looking forward is an advantage and the oars are an impediment.

I have thoroughly enjoyed being out in this boat and would recommend it to beginning as well as more experienced rowers. It will be a fine boat for all those wanting to get out on ponds, lakes, and streams.

Karen Naughton

Karen NaughtonThe Guideboat rows well with three people on board. The lighter passenger should be in the bow for the best boat trim.

I’m not alone in highly recommending a Newfound Woodworks kit. I entered my Adirondack Guideboat in the 2024 WoodenBoat Show at Mystic, Connecticut, and was amazed by the number of folks who stopped by to tell me they, too, had built one of Newfound Woodworks boats and were also very happy with the outcome.

So, buy the kit, build the Guideboat, and have fun rowing.![]()

Steve Petty resides in Sherborn, Massachusetts, a small town west of Boston with access to the Charles River and Farm Pond. He grew up rowing and sailing and canoeing on both the river and the pond. He spent many summers on the North Channel of Lake Huron where boating was a necessity since camps were only accessible from the water. In the early 1980s, he, his wife, and two children motored their Albin Trawler from Cos Cob, Connecticut, to Lake Huron via rivers, canals, and lakes. Steve is an experienced carpenter and has been involved in timber framing for 50 years.

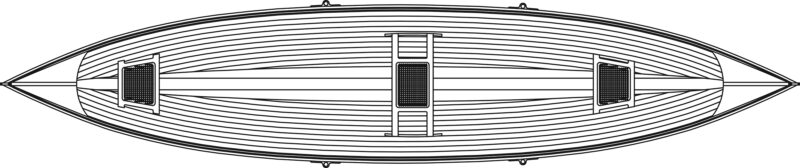

Adirondack Guideboat Particulars

Length: 16′ 2″

Beam: 37″

Weight: 70 lbs

Capacity: 480 lbs

Draft: 5 1⁄2″

Center depth: 12″

Depth at bow: 25 1⁄4″

The Adirondack Guideboat kit is available from Newfound Woodworks for $3,480. The set of caned seats are an optional kit at $183.50.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats readers would enjoy? Please email us your suggestions.

Nice project and a beautiful boat!!