22'6" Recreational Shell Kingfisher

The original print version of this article can be viewed as a PDF or purchased from the WoodenBoat Store.

Join to view PDF Purchase 22'6" Kingfisher Shell PlansThose who know the sport of rowing know Graeme King to be one of the world’s top designers and builders of wooden racing shells. The rowing shells that come out of his King Boat Works are built not only to stand the test of time, but have also put their crews and designer in the record books. The Harvard and Navy crews, as well as other outstanding crews, use King-designed boats.

Kingfisher Particulars

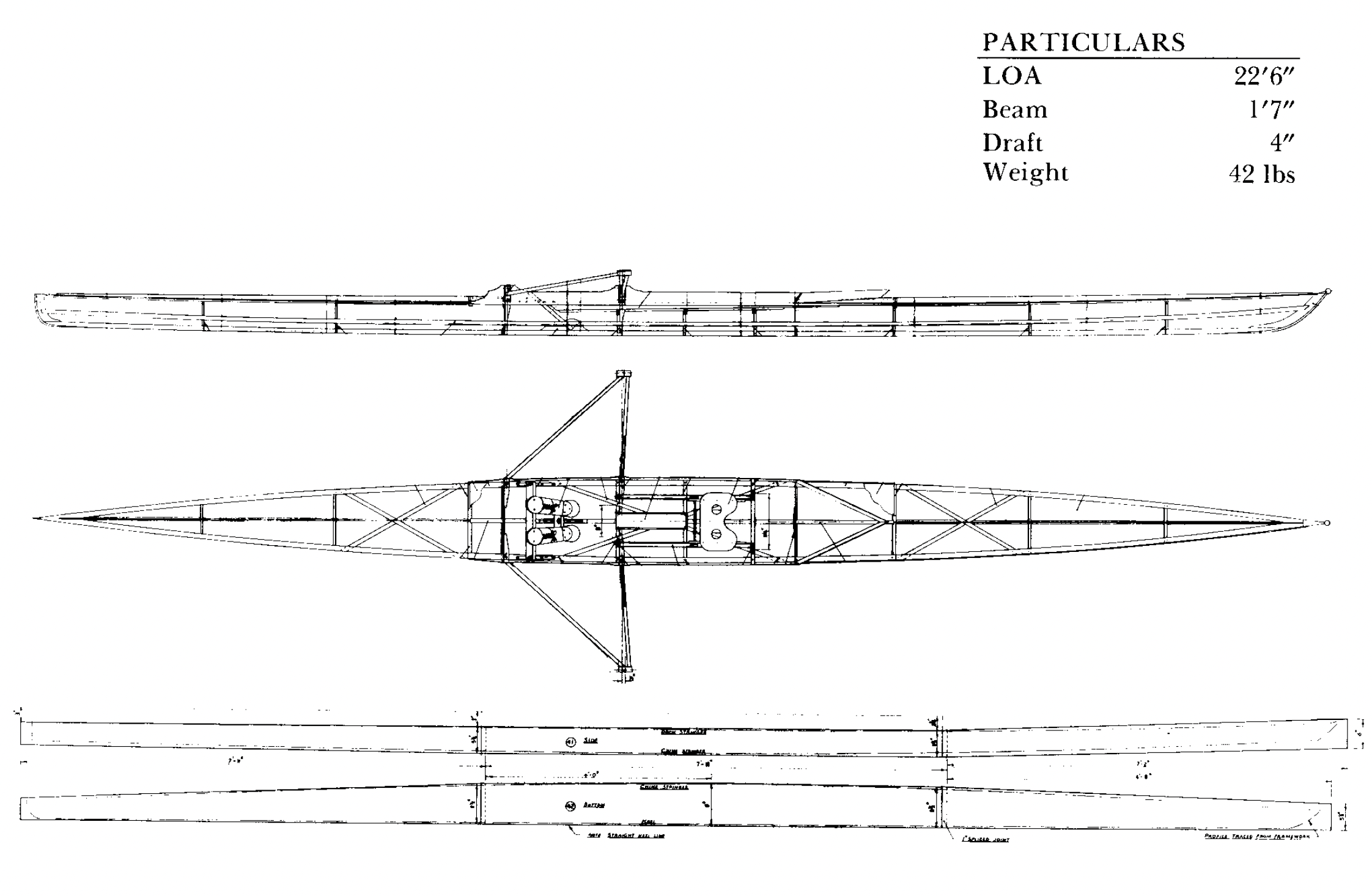

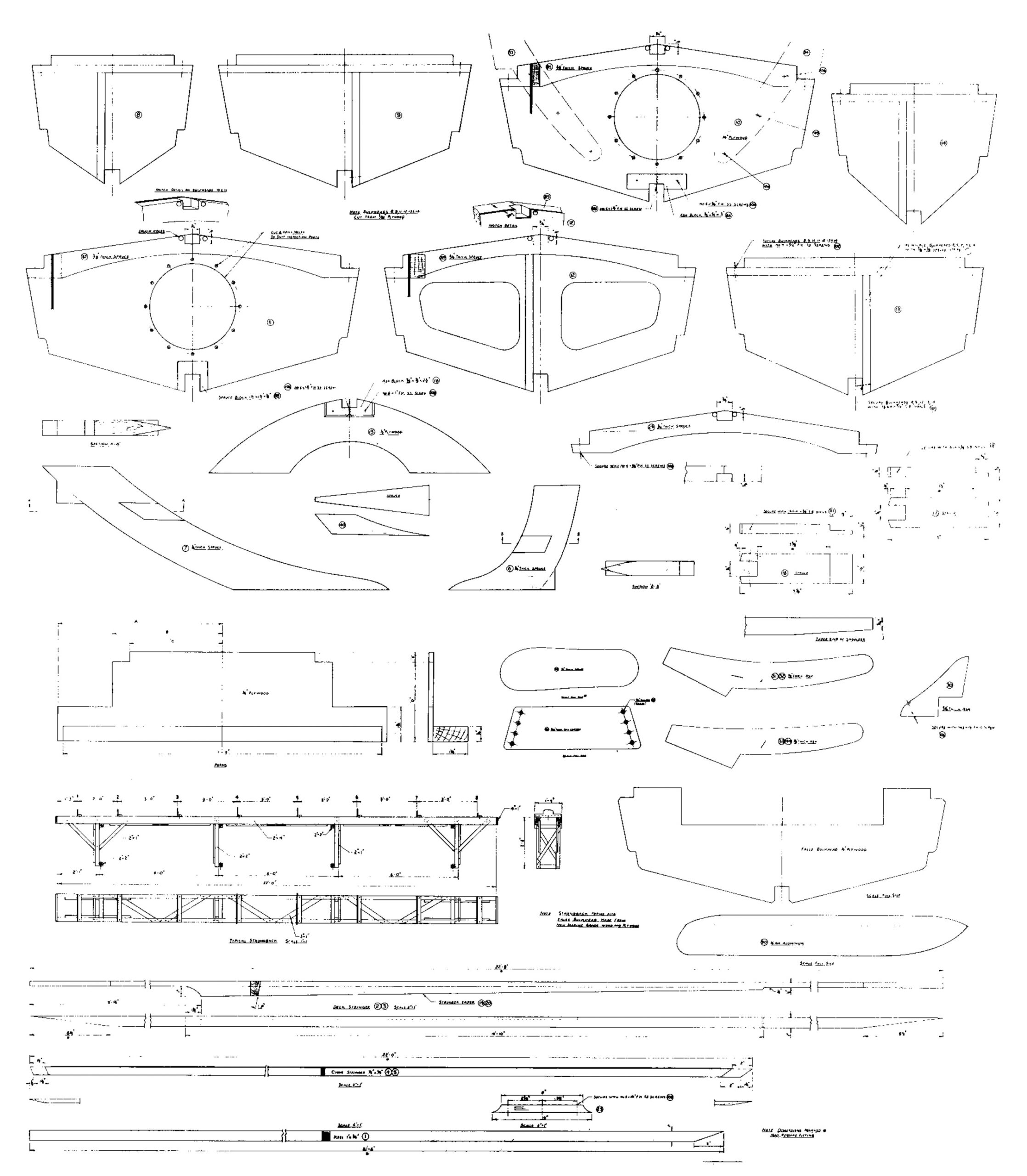

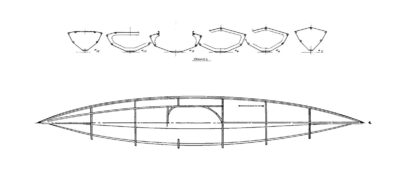

Recognizing a strong resurgence in recreational rowing today, WoodenBoat commissioned King to design a single shell that the home builder would be capable of constructing. The result is the Kingfisher Shell, a graceful, V-bottomed shell that does not require a lot of expensive jig and mold making, and is very well suited to one-off construction by the amateur builder with intermediate boatbuilding skills.

Stability is a delicate matter in a shell, as any beginner discovers when he or she first settles onto the sliding seat! Kingfisher’s 1’4″ waterline beam provides a good compromise, giving inexperienced rowers a shell they can learn to handle, but also proving to be very satisfying to the experienced oarsman. She can be rowed in a variety of conditions, ranging from a glass-smooth river to a two-foot open bay chop (only the oarsman very familiar with shells, of course, should try to row in anything but smooth water). The prototypes were thoroughly tested in two pulling boat races (which included a variety of other shell designs), one on Narragansett Bay off Newport, and one in Boston Harbor in very rough conditions. The boat proved to be excellent to row on flat water, handled chop very well, and had a surprisingly fast turn of speed; she won both races handily. Intended as a recreational rather than all-out competition boat, Kingfisher can still reach an estimated 93% of the speed of the best competition shells.

Construction is of 3/32″ or 1/8″ mahogany plywood for the hull and bulkheads, with spruce stringers and a deck of shrunk Dacron. The boat is 22’6″ overall, l ‘7″ beam, and has a 4″ draft. With a weight of only 45 pounds, she may be readily transported to your rowing site on a car roof, and is easily carried by one person. A key to comfortable and efficient rowing is the rigging, as the designer knows very well, having formerly been rigger for the Harvard crews and the U.S. National teams.

Kingfisher Patterns

The four sheets of plans for the Kingfisher Shell include general arrangement, fitting details, bulkhead details and strongback, keel and patterns. WB Plan No. 51. $75.00.

A complete construction kit for the Kingfisher is also available from King Boat Works, and the kit comes with everything you need to build your boat, except varnish and oars. For those who are building from plans, outriggers and hardware can be purchased separately from King Boat Works as well. Write to WoodenBoat for details.

Completed Kingfisher Shell Images

Photo by Karen Wales

Photo by Karen WalesGraeme King (shown) has devoted his career to designing and building wooden rowing shells. He developed the Kingfisher single for the home builder who desires a fast and elegant recreational shell.

Photos by Karen Wales

Photos by Karen WalesKing builds the specialized sliding-seat mechanism and outriggers required by the Kingfisher and Kookaburra. Lightweight oars are purchased separately.

Kingfisher Details

Photo by Karen Wales

Photo by Karen WalesHere is hull No.1 of nearly 1,000 Kingfishers that have been built over the past 25 years. Her sapele plywood hull glistens in the afternoon sun.

Photo by Karen Wales

Photo by Karen WalesThe Kookaburra is a double version of the Kingfisher. Like its predecessor, the Kookaburra double is a fast and able recreational shell. Long, quiet expanses such as straight rivers and oblong lakes provide the best conditions for this type of craft.

Great boat designed by a true craftsman and nice guy. I built a Kingfisher and enjoyed rowing it back in the 1980-1990s. Later, I visited Graham at his Vermont workshop, where I gave him some samples I made of fiberglass and carbon fiber. In return, he gave me blueprints for a racing single sized to me. Your article was nostalgic for me. I am not sure, but the King Boat Works may not be operating. Check it out before buying plans from Wooden Boat or anyone else. The custom made-metal parts, outriggers, may not be available and are not the size of other commercially available boats. You can probably find parts for the sliding seat, rails, and oarlocks from other suppliers.

I rebuilt an old Kingfisher with Graeme King’s help, and also have built three of his strip-built racing and recreational shells. No, I don’t think he is around anymore. He retired and planned to move back to his native Australia, selling his shop in Putney, Vermont. Making the seat and foot stretcher for a Kingfisher should be no problem. It is straightforward work, and special parts including the sliding seat and tracks can be purchased ready made. Wintech is one place that sells them. The riggers call for custom work by a welding shop and will cost more than Graeme charged (skilled in machine shop work, he made riggers for me in powder-coated stainless, and they are different for each of my King boats). The key thing is to get the angle correct where the rigger attaches to the topsides of the hull. That determines the height of the oarlocks above the water, and that is all important. Oarlocks are stock items. I bought from Concept 2.