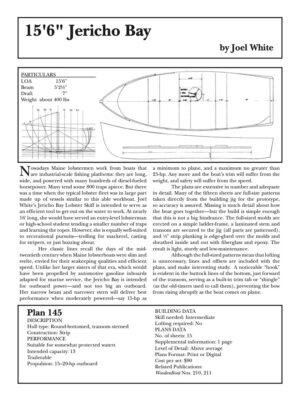

15'6" Jericho Bay Lobster Skiff

The original print version of this article can be viewed as a PDF or purchased from the WoodenBoat Store.

Join to view PDF Purchase Jericho Bay Lobster Skiff PlansNowadays Maine lobstermen work from boats that are industrial-scale fishing platforms: they are long, wide, and powered with many hundreds of diesel-fueled horsepower. Many tend some 800 traps apiece. But there was a time when the typical lobster fleet was in large part made up of vessels similar to this able workboat. Joel White’s Jericho Bay Lobster Skiff is intended to serve as an efficient tool to get out on the water to work. At nearly 16′ long, she would have served an entry-level lobsterman or high-school student tending a smaller number of traps and learning the ropes. However, she is equally well-suited to recreational pursuits—trolling for mackerel, casting for stripers, or just buzzing about.

15’6″ Jericho Bay Lobster Skiff Particulars

Her classic lines recall the days of the mid-twentieth century when Maine lobsterboats were slim and svelte, envied for their seakeeping qualities and efficient speed. Unlike her larger sisters of that era, which would have been propelled by automotive gasoline inboards adapted for marine service, the Jericho Bay is intended for outboard power—and not too big an outboard. Her narrow beam and narrower stern will deliver best performance when moderately powered—say 15-hp as a minimum to plane, and a maximum no greater than 25-hp. Any more and the boat’s trim will suffer from the weight, and safety will suffer from the speed.

The plans for the Jericho Bay Lobster Skiff are extensive in number and adequate in detail. Many of the 15 sheets are full-size patterns taken directly from the building jig for the prototype, so accuracy is assured. Missing is much detail about how the boat goes together—but the build is simple enough that this is not a big hindrance. The full-sized molds are erected on a simple ladder-frame, a laminated stem and transom are secured to the jig (all parts are patterned), and ½” strip planking is edge-glued over the molds and sheathed inside and out with fiberglass and epoxy. The result is light, sturdy and low-maintenance.

Although the full-sized patterns mean that lofting is unnecessary, lines and offsets are included with the plans, and make interesting study. A noticeable “hook” is evident in the buttock lines of the bottom, just forward of the transom, serving as a built-in trim tab or “shingle” (as the old-timers used to call them), preventing the bow from rising abruptly as the boat comes on plane.

Plan 145

DESCRIPTION

Hull type: Round-bottomed, transom sterned

Construction: Strip

PERFORMANCE

Suitable for somewhat protected waters

Intended capacity: 13

Trailerable

Propulsion: 15–20-hp outboard

BUILDING DATA

Skill needed: Intermediate

Lofting required: No

PLANS DATA

No. of sheets: 15

Supplemental information: 1 page

Level of Detail: Above average

Plans Format: Print or Digital

Cost per set: $90

Related Publications:

WoodenBoat Nos. 210, 211

Completed 15’6″ Jericho Bay Lobster Skiff Photos

Matthew P. Murphy

Matthew P. MurphyThe Jericho Bay Lobster Skiff seen here is a strip-planked, fiberglass-sheathed copy of a plank-on-frame hull designed by Joel White and built by Jimmy Steele in the 1970s.

Bulkheads under the seats enclose storage compartments and serve as framing to reinforce the glued-lap plywood construction.

James’s lapstrake version of the skiff made it lighter and easier to maintain than the carvel originals.

Photographs courtesy of Bob and Beth Burns

Photographs courtesy of Bob and Beth BurnsOn it’s inaugural outing LIBBY B lived up to her builder’s expectations.

A nice 2-stroke would be better than a 4-joke. More acceleration, more speed, way lighter, way less cost. When production costs, crankcase oil disposal, 4-jokes in the shop more often with expensive shop costs, and the small number of 2-stroke outboards compared to cars, the environmental and social costs of 2-strokes rapidly declines. Upper Midwest still has many 2-strokes, and the water is cleaner than ever, and the fish are abundant.

‘Crankcase oil disposal’ on a 4-stroke? At least it’s going somewhere under control. The 2-stroke I use at work is factory spec’d to pump a quart of oil into the water or air with every 10 gal of fuel she burns. Even when I use the boat for only 10-15 minutes. I can taste the oil on my tongue for days.

Loud too. If I want to talk to anyone off the boat I have to shut her down.

Edit- My boss told me a quart per 10gal, but jug says quart per 12gal. After I changed to 12gal, the smoke hasn’t noticeably lessened.

It really is phenomenal when considered. A full quart of oil smoked into air and water per good day on the water.

My only disagreement would be with the statement “But there was a time when the typical lobster fleet was in large part made up of vessels similar to this able workboat”

The lobster fleet started as sailboats and progressed to what we see today. At no point were a large group of fisherman using 16′ boats. I think William Frost’s early boats like Red Wing and Thoroughbred would be the closest at 33×7 with 24hp. Still a different animal. Jericho has a L/B ratio of 2.98 Red Wing is at 4.71.

Nonetheless Jericho is a beautiful boat.