From childhood, Geoff Hart has been interested in boats and boatbuilding. His father, an amateur builder of small boats, built a skin-on-frame boat that he kept upside down in the yard of the family home in Miami. “A neighborhood kid, a little older and bigger than me,” recalls Geoff, “was running up and down on the upturned boat and put his foot right through the bottom. My father was fit to be tied. After that he only ever built in plywood.” Indeed, his father went on to build a couple of sailboats, an outboard runabout, and a 9′ pram dinghy with a Bermudan rig that he built for Geoff as a Christmas gift. As a teenager, Geoff helped his father from time to time and remembers that he “never bothered with lofting but instead would work straight from the table of offsets.”

Geoff took his first class at WoodenBoat School more than 20 years ago, joining a team of students building a traditional Norwegian pram with Bob Elliott. He returned some years later for the Fundamentals of Boatbuilding and then Advanced Fundamentals of Boatbuilding with Greg Rössel. He followed those with Elements of Boat Design with Paul Gartside, and finally Bronzecasting for Boatbuilders with Michael Saari, commenting, “Casting is like snow-skiing—way more difficult than it looks.”

Geoff Hart

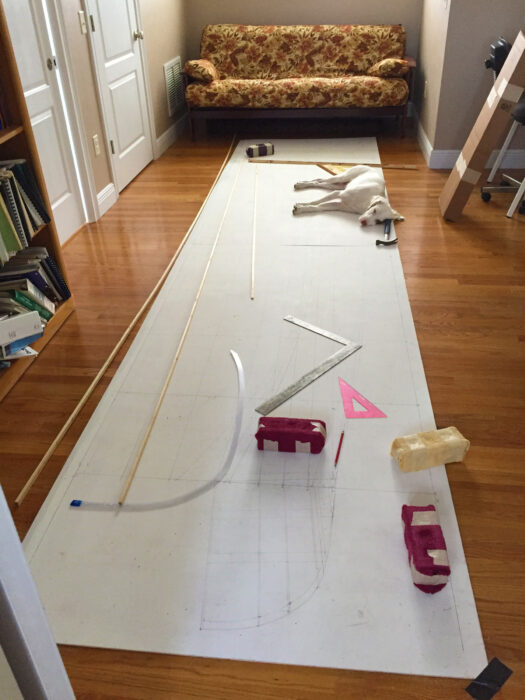

Geoff HartGeoff’s office floor became the ideal space for lofting, although the family English setter was not always the most efficient assistant.

While he was accumulating knowledge through the classes, Geoff was building and dreaming on his own. He built a strip-planked Wee Lassie but wanted to try his hand at traditional construction. He acquired some rudimentary plans for a 12′ × 4′ 7 1⁄2″ Snow Bird, a 1932 Frostbite dinghy designed by C.D. Mower. They had been published in a 1955 issue of How to Build 20 Boats by the editors of The Rudder magazine (reprinted from the April 1933 issue of the magazine itself), and consisted of offsets and drawings on two 6″ × 9″ pages along with the advice that “Anyone who has had any experience building round-bottom clinker-built dinghies will find sufficient information on these pages to enable him to build a Snow Bird for himself.”

Geoff had no “round-bottom clinker-built” experience but decided to give it a go. He enlarged the plans. “In the originals,” he says, “some of the numbers were so small you couldn’t possibly read them. Even enlarged, the plans were very basic. What was there was good, but there was almost no detail.” Geoff thought back to his father’s habit of building from offsets and decided, “There was no way. I would have to loft it full size.” He laid out several sheets of plywood on the floor of his office and spent “a couple of weeks wearing kneepads, crawling around on the floor, and shifting the sleeping English setter who kept me company.”

Once lofted, he moved the project out to a bay in the barn near the house. It would be there for the next four years. “I’d leave it for a couple of months here and there, but it was very involved and there was a steep learning curve at every stage.”

Geoff Hart

Geoff HartGeoff set up the molds and then laminated frames around them. Subsequently he set up ribbands and installed the remaining laminated frames at 8 1⁄2″ centers.

Geoff built the hull upside down on molds. The plans suggested white oak for the keel and frames and cedar for the planking. But, unable to find white oak locally, Geoff decided to laminate the frames out of bald cypress. “They’re 3⁄4″ × 3⁄4″ spaced at 8 1⁄2″ centers, and there are a lot of them,” he says. “But not as many as the original—those were narrower and spaced every 6″. I made mine wider so I could screw into them.” He also added floor timbers at every other frame. “I wanted extra strength in the bottom, mostly because the boat was going to live on a trailer.” For the planks he used 5⁄16″× 6″ cypress boards, nearly all of which had to be scarfed for length.

For Geoff, the project was constantly challenging. “I truly did spend as much time thinking as I did building. The first time I attempted to fit the garboard, it broke. I remembered Greg Rössel’s steaming tips and bought a wallpaper steamer.” But before he even started planking, Geoff had to figure out how many planks he was going to need. He drew a full-scale diagram and figured out he could use 9, 10, or 11 planks per side. “If I’d used 11, they would have been too narrow to take two screws to the stem, and nine planks would have been too wide in the garboard and at the turn of the bilge.” He settled on 10 per side.

The original boat was very lightly built, Geoff says. The planking was in cedar and Geoff’s cypress would be slightly heavier but also stronger. He decided not to rivet the entire hull. “I knew where the stress would be greatest, so I riveted the full length of the garboard and two broadstrakes, but the other planks I riveted only from the bow to just aft of the maststep.” His wife stepped in to help with the riveting in the bottom of the hull. “A little of that went a long way with her,” he says. “She told me she was going to file a grievance with the Under-Boat Workers of America.”

Geoff Hart

Geoff HartThe planking almost complete, the sheerstrake is clamped in place. Riveting has also begun in the bottom planks.

Geoff fastened all the plank laps to the frames with bronze screws (mostly inherited from his father) and, on the outside of the hull, applied adhesive caulk to the inside corners of the laps to seal the seams. “The climate here in Florida is pretty humid—wooden boats don’t dry out like they might in the Northeast if you haul them for the winter. I wasn’t worried about the planks splitting.” When he launched SNOW BIRD, Geoff says, “she didn’t leak a drop.”

Knowing that his choice of wood had added weight to the hull, Geoff sought ways to reduce weight elsewhere. The transom, he says, was designed for 3⁄4″ oak; he used 7⁄16″ cypress. He fashioned the centerboard from fiberglass, 7 lbs lighter than the specified metal. He hand-laid the board on a mold to the same basic dimensions as the original. When finished, it weighed 16 lbs, which he thought would be heavy enough to overcome its own buoyancy. “At the dock it went down just fine, but once I got going, the board just wouldn’t sink.” He took it out, cut a 6″-diameter hole near the bottom, and had a local metal shop fabricate a 3⁄8″-thick mild-carbon steel plate, which he ’glassed into the hole. It added 2 lbs of weight and, says Geoff, “worked like a charm.”

Geoff Hart

Geoff HartWith the hull fully planked up, Geoff turned the boat over and began the fit-out. He built the centerboard trunk to the plans although, knowing he would be laying up a fiberglass board with squared off bottom edge, he also squared off the aft end of the trunk.

Mower’s design adhered to the 1930s Frostbite class rules. The boats were required to have three thwarts plus a mast thwart. “In a 12′ boat that’s pretty tight. It doesn’t leave room to turn around. I took out the forward thwart. The rules also specified small buoyancy tanks. They were probably big enough to keep the boat stable and upright after a capsize, but I decided to increase them, making them as large as possible while still fitting under the center thwart.”

The rig, says Geoff, is essentially as designed, although he increased the sail’s luff by a foot, which changed the area from 72 sq ft to 80 sq ft but didn’t alter the longitudinal center of effort. He also lengthened the mast from 11′ to 12′ 6″ to accommodate the taller sail. “I built it box-section out of Douglas fir rather than the original solid spruce, so it’s lighter but stronger. It’s tapered in both directions, which made it hard to build. I had one joint that was horrible, and I decided I couldn’t live with it. I spent four hours with a heat gun popping the epoxy glue loose and taking it apart so I could clean it out and redo it.”

Patty Hart

Patty HartThe original Snow Bird design showed smaller buoyancy tanks, more frames, and a removable forward thwart, otherwise Geoff’s new build would have looked like her sisters of the early 1930s.

While Geoff has been sailing since he was a child, the lug rig was new to him and, like everything else in this project, “involved a lot of learning. I’m still fiddling with it, trying to get it just right. Every time we use the boat, I raise the sail a little higher and adjust the downhaul, looking for that perfect set.”

Sail-setting aside, SNOW BIRD has more than lived up to Geoff’s hopes. After four years in the barn, she emerged and was launched in the summer of 2023, and, two summers on, Geoff is very happy with her. “I haven’t sailed her in more than 10 knots of wind,” he says, “but she’s surprisingly fast on a close reach.” When sailing, he sits on the cockpit sole, “because that’s how I learned.” He uses the center thwart when rowing, and the sternsheets when motoring. He has made the aft thwart removable. “If I didn’t have the motor, I’d probably just take it out, but it is nice if there are two people and one is rowing, it’s somewhere for the passenger to sit. We’ll see.”

Patty Hart

Patty HartGeoff increased the sail’s luff by a foot, which increased the sail area by 8 sq ft—that extra canvas helps SNOW BIRD to move in even the lightest of breezes.

Like so many other builders of small boats, Geoff will no doubt go on tinkering and looking for things to improve, adjust, or tweak. But that is surely part of the fun. For now, SNOW BIRD sits on her trailer ready to go for a sail whenever the skipper and the riveter have some free time.![]()

Jenny Bennett is editor of Small Boats.

Do you have a boat with an interesting story? Please email us. We’d like to hear about it and share it with other Small Boats readers.

That is one very salty craft!! Great job!