I often have an awkward and anxious moment when I’ve finished a cut on my tablesaw or bandsaw and have to reach down to turn the machine off while still hanging onto the workpiece. While I’m groping for the little toggle switch beneath the table, I have to keep my eye on the racing blade, the workpiece, and my fingers. Aside from my safety, some cuts can bind and stop bandsaw and tablesaw blades, and I need to shut the motor off as quickly as I can before something gets damaged. To add an element of safety, I bought some switches that are easily and quickly operated.

Photographs by the author

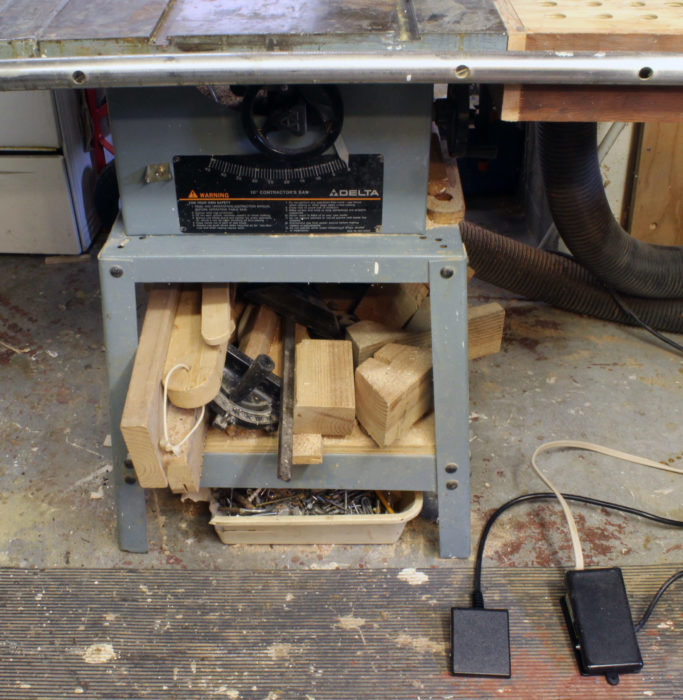

Photographs by the authorThe small toggle switch that came with the tablesaw is small and tucked under the table. It’s not set up for quick operation.

I bought two different foot switches, both “power-maintained”—push once for on, push again for off. (There are “momentary” foot switches that cut the power when you lift your foot.)

The foot switch I chose to use for my tablesaw is the prosaically named S420-1501 by SSC Controls. It has a sturdy steel housing with textured rubber pads top and bottom for a non-slip surface. The 8′ cord has a “piggyback” plug with prongs on one side to plug into the power outlet and a socket on the other side to receive the tool’s cord. The single cord is an improvement over the Two-Step’s two: one out the back and another out the side. The switch built into the S420 has a steel arm with a roller. Pressed down it connects the circuit, released it breaks it, so it is actually a momentary switch. It’s the housing that makes the S420 power maintained. The base has a spring and bullet catch. The pedal has a hole in the back to engage the catch. When the back of the pedal is pushed down, the switch closes the circuit and the catch holds the pedal. Pushing the front of the pedal frees the catch and then the spring holds the pedal up with the switch in the off position. SSC manufactures a similar foot switch, the S400-1501, in a momentary configuration and likely identical to the S420 but without the bullet catch.

The S420-1501 has a steel body and operates as a treadle: Press the high end for “on,” and the low end for”off.”

The S420 doesn’t have screw holes for anchoring it to the floor. Aside from having a concrete floor, I find it useful to move the switch. For feeding long pieces into the tablesaw, I can slide the switch out from the saw, set the workpiece up, and turn the saw on. As I feed the wood through the blade and onto the outfeed rollers, I can nudge the switch ahead of me and turn the saw off at the end of the cut.

With its piggyback plug, the S240 is easy to move to other tools—whether bench tools like a drill press or hand tools like a Dremel—where hands-free operation might be an advantage.

The Two-Step Foot Switch from Harbor Freight I use for my dust collector has a plastic body that is 1/8″ to 5/32″ thick, and seems sturdy; we’ll see how long it lasts on a concrete floor among a lot of heavy things. The switch has a 7-1/2′ cord and a grounded outlet, which the tool’s cord gets plugged into. Inside the housing is a spring and a plunger switch; one tap on the pedal turns the power on, a second tap turns it off. The base has flanges on either side and tabs front and back, all with screw holes for mounting.

The Two-Step is operated by pressing the high end, once for “on” and a second time for “off.”

The Two-Step switch for my dust collector sits next to the tablesaw foot switch for more convenient operation than moving to the collector. Both switches remain operational when those tools are no longer being used and susceptible to being tripped unintentionally, so at the end of a stint in the shop, I turn the machines’ original switches off.

I have the two pedals side by side. One on the left for the tablesaw and the other on the right for the dust collector.

My 1989 Delta 14″ bandsaw, like the tablesaw, has a small toggle switch located on the base. More recent bandsaws have magnetic switches with large on/off buttons mounted on the column, above and to the left of the table. The location is good; I wanted my new switch to be more prominent and easily operated by a quick slap of the hand or the press of an elbow. A paddle switch adds a large pivoting lever over the off button and framing the on button; hitting it anywhere cuts the power.

The large and easily operated paddle switch, bolted to the bandsaw column, replaced the small toggle switch on the tool’s stand.

I bought the Woodstock D4160 Paddle Switch. As a fixed installation, a paddle switch requires some rewiring. The toggle switch breaks the circuit at hot lead alone; the paddle switch breaks the neutral lead as well, so it needs some additional wires to function. I added two wires to the original cord cut from the toggle switch. I set the switch in a steel junction box bolted to an existing hole in my bandsaw’s column, a location that is close at hand and easy to operate, even with my elbow.

These simple switch upgrades were inexpensive and were good investments in convenience and safety.![]()

Christopher Cunningham is the editor of Small Boats Magazine.

The Two-Step Foot Switch from Harbor Freight costs $13.99. The S420-1501 by SSC Controls costs $25.25 and is available from SSC and online retailers. The Woodstock D4160 Paddle Switch is available from selected retailers and through Amazon for $11.70.

Is there a product that might be useful for boatbuilding, cruising, or shore-side camping that you’d like us to review? Please email your suggestions.

I want to add a paddle switch to my Delta 28-560 band saw that I’ve reconditioned. The current switch is just 2 prong. Can you send me a video please on how you did the rewiring?

Get the SSC Controls switch. It’s made in America.