SBM photographs and video

SBM photographs and videoThe StopLossBag system offers a way store paints and varnishes without the exposure to air that causes the contents of a partially used can to skin over.

StopLossBags provide a unique solution to a common problem. We’ve all been there. You’ve got a little bit of wear in your varnished rubrail, and it just needs to be touched up to keep it Bristol. You grab that can of varnish you know is at least half full, but you discover that it has skimmed over with a hardened amber-colored hockey puck on top. You then spend the next half hour straining what’s left of the still-liquid contents out into a new container. The quick touch-up has turned into a messy project and much of that expensive varnish has been lost.

The connection between the funnel and the bag spout is a slip fit that holds as long as both are dry and you’re careful not to pull them too far apart while pouring. Both the author and the editor inadvertently separated the connection in mid-pour, spilling some of the cans’ contents and discovering that the bag and funnel cannot be reconnected when slippery with paint or varnish. The instructional video on the StopLossBag website shows the joint being pinched by hand during the pour. A small hose clamp provides a secure hands-free connection. The clamp only needs to tight enough to gently pinch the funnel nozzle against the threads at the base of the bag’s spout.

StopLossBags are collapsible 1-liter (1.05-quart) bags that eliminate the open space, and therefore, exposure to air, which triggers curing in paint and varnish. The top of the bag has a spout with a twist-on cap. The bags are especially handy when you need only a small amount of finish. You can quickly pour out the exact amount you’ll use without fussing with a crusty lid and having the contents dribble all over the can.

Prior to the pour, the bag must be inflated for the contents to flow in from the can.

I tested the bags with Interlux Brightside Polyurethane Topside Paint and Epifanes Varnish. The collapsible, reusable funnel available with the StopLossBags simplifies transfer between a standard quart can and the bag. The rubbery funnel’s wide end stretches around the open end of the can, creating a secure seal, and its nozzle then connects around the spout of the StopLossBag. Flip the can upside down while holding the bag, and the contents transfer without the mess you’re likely to make pouring from the open can into a rigid funnel. In testing, varnish easily transferred into the bag; I had a little more trouble transferring paint. It was a little too thick to easily flow into the spout. Pumping the funnel helped coax it along.

Before putting the cap on, the bag is squeezed to push the contents to the tip of the spout, eliminating air space. Here, the clear area at the top of the bag is devoid of air; the front and back surfaces are mostly in contact with only a thin transparent layer of the product between them. The funnel was set aside to dry.

After the material flowed into the bag, I disconnected the funnel and squeezed the air from the bag per the instructions before sealing it with the twist-on cap. For cleanup, I let the funnel dry, then peeled off the dried film the next day. I used a little denatured alcohol on a rag to wipe off some residual flakes.

The interior surface of the funnel has a slick glossy finish, making it easy to remove dried paint or varnish after use.

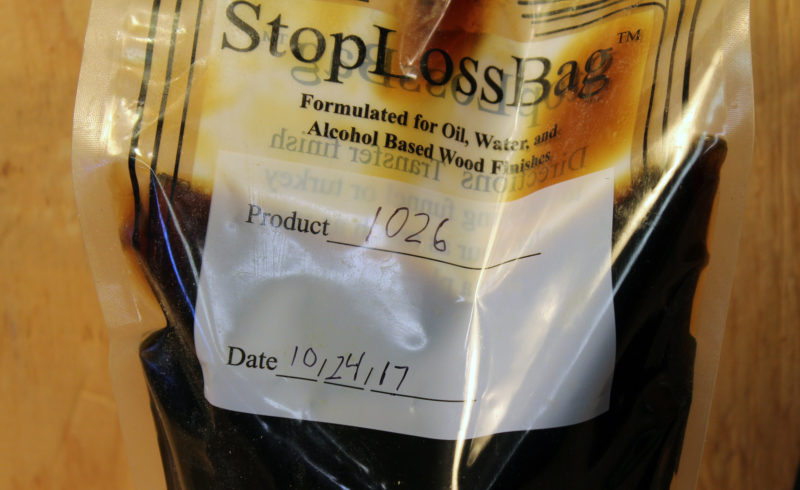

StopLossBags have a labeling area on one side so you can record what you put in it and when it was transferred. A Sharpie pen writes well on the plastic surface. The bags are stiff enough to stand up on their own, which makes them store neatly on the shelf.

One side of the bag has a space for identifying what is in the bag and when it was poured. Alcohol will remove the permanent marker when the bag is reused and requires new labelling.

At the Center for Wooden Boats, we often have multiple varnish projects going on simultaneously, and these bags organize mixes of various ratios of varnish to thinner for quick use. The bags have the added benefit of easily allowing small amounts of finish to be dispensed. Even the slow-flowing paint was easy to dispense by squeezing the bag.

On each bag is printed: “Not for use with finishes containing acetone, benzene, lacquer thinner, MEK, toluene, or xylene.” However, Interprime Wood Sealer (Interlux 1026) is a popular product containing xylene and is notorious for quickly skimming over. The StopLossBag’s manufacturer had reported that lacquer thinner and acetone have led to a softening of the bag’s plastic laminate, but when we asked about xylene they said they hadn’t specifically tested it, so we gave it a try by filling a bag with straight xylene. After a few weeks the StopLossBag was holding up perfectly with no signs of softening. Maybe now we’ll be able to use a whole can of the sealer without having a good portion of it turn gummy. The bags can be reused after cleaning. I had good results filling them with some denatured alcohol and swishing it around the bag. The alcohol can also be used to erase the Sharpie pen for relabelling.

I’ve tried an argon-gas product meant to prevent skinning, but had little success with it. Some folks on the web suggest using a circle of waxed paper to prevent skimming, but that seems like a messy solution to me. The StopLossBags are a tidy, effective way to store different types of finishes that are going to be used over a prolonged period. The cost of the bags is easily recouped when good finish is prevented from skinning over.![]()

Josh Anderson attended the Apprenticeshop

StopLossBags are available from the manufacturer and from Duckworks. Prices vary with single bags priced at $4.95 and sets of bags reducing the cost to $2.75 apiece. The funnel is priced at $5.98 and $7.95, depending on the vendor.

Is there a product that might be useful for boatbuilding, cruising or shore-side camping that you’d like us to review? Please email your suggestions.

I’ve had mixed success with filling partial cans of product with argon. So I just may give these bags a try. They do seem a bit unstable during the fill process, but small wooden support box would be easy to make and just might prevent a big mess. Thanks for showing this.

Been using these for several years for varnish and Cetol Marine and their gloss product. Work great! But rather than using a funnel which I found wasted too much of the pricey elixir, I use a 150 mL disposable plastic syringe to transfer out of the can into the bag. When finished, a quick rinse with paint thinner let’s you use the syringe many times over. Eventually the rubber tip on the plunger swells up and makes it dfficult to slide. But eBay has these syringes for very reasonable prices. Actually I also use them for transferring latex paint whenever I have the need for small amounts. No Stoploss bags required for these.

The StopLoss bag filled with xylene-based 1026 is still in great shape 8 1/2 months later and shows no sign of being degraded. The 1026 is also in great shape. If it were still in the can, a good portion of it would have been lost to skinning.

I just sent a message to Duckworks about these clever bags. I have reduced eight partial cans of varnish and boat paint to eight bags that fit in one shoebox. Great space saver, and excellent if using mixed paints with flattening agents so that the gloss is consistent for touch up until your bag runs out. Some method of support for the bag and funnel is necessary when filling, I’ve found, after cleaning a large expensive puddle from my workbench.

We have been using these bags for several years with great success. Recently I came across a bag of Epifanes varnish for 2019. I opened it, added a touch of naphtha and started varnishing. No problems at all. Great product.