Sibley family

Sibley familyPeter stands behinds JIM, its sails newly raised and sitting on the trailer he built. Above him is the sign on his shop that reads: “Optimists only beyond this point.”

Peter Sibley and his wife Carole live in Murwllumbah, New South Wales, a dozen miles from Australia’s east coast, 19 miles if you go by boat down the Tweed River. Peter had set out to build a French pilot cutter that he had redesigned with the help of the late yacht designer Ed Burnett of Devon, England.

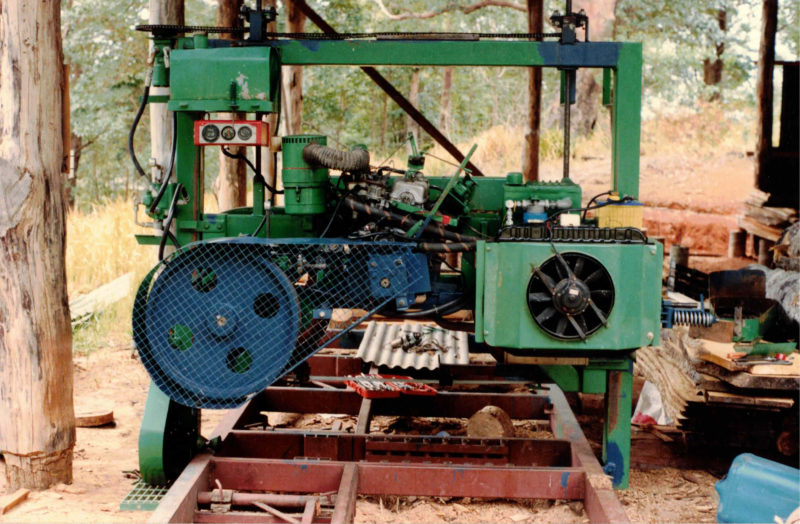

Wanting to do as much of the work as possible in his own shop, he started with logs, and that required some special equipment. He had once run a sawmill business, and for transporting logs, he had designed a gantry crane that he mounted on a flatbed truck; once he had the logs at his shop, he slabbed them with a horizontal bandsaw mill that he’d built, complete with hydraulic controls. To make his own bronze hardware for the cutter, he set up a separate foundry with a large furnace and made his own wooden patterns.

Peter had laid the keel for the cutter and was fully invested in the project when he had to bring it to a sudden and unexpected stop. One of his daughters was taken ill, and he and Carole devoted themselves to the care of their daughter and her children.

Peter still had bits of free time to devote to boatbuilding, but he needed to scale back. He shelved the cutter project and tossed around various designs as alternatives on the Woodenboat Forum, where over the past 18 years he has made over 74,000 posts and was recently elected BROTM, Bilge Rat of the Month, by his friends who inhabit The Bilge, the forum’s no-holds-barred venue. Peter didn’t find anything that was just right, so he commissioned Antonio Diaz to create a new design, the 24′ Kathleen Gee, a stout-looking little yawl drawn in the tradition of the small coastal cruisers by C.P. Kunhardt, author of Small Yachts: Their Design and Construction.

Life’s demands, as they often do, grew and occupied more of Peter’s time, and the Kathleen Gee, with a displacement of 10,000 lbs, was too ambitious a project to take on. He looked for an even smaller boat and found himself drawn to the lug-rigged yawls popular among camp-cruisers. He ultimately settled on an 18′ 4″ canoe-yawl, Jim, designed by Paul Fisher of Selway Fisher in Melksham, England. It was designed for stitch-and-glue plywood construction, but Peter preferred the more traditional look of lapstrake, so Paul advised building the design in glued lapstrake and drew up a lug sail in place of the gunter mizzen.

Duncan Gibbs

Duncan GibbsWith a crew of friends aboard, Peter takes JIM’s helm for the boat’s first sail.

Peter began work on his Jim in 2012. He put his pattern-making skills to use and had bronze rudder and stem hardware cast from wooden patterns he’d made specifically for the boat.

As 2015 drew to a close, Peter had nearly finished the build, but the project was brought to a sudden halt. Peter was given a diagnosis of an aggressive brain cancer in its final stage. He had surgery on the tumor, but not all of it could be removed. Peter received a dose of chemotherapy and radiation, but his prognosis was grim. He was given six months to live.

A sign hanging in the front of Peter’s boatshop reads: “Optimists only beyond this point.” Peter applies that directive not only to his boatbuilding, but also to living. Six months came and went. Peter needed a trailer for the canoe-yawl. None of the commercial trailers available would have been a good fit for the boat’s pronounced rocker or the hull’s wineglass cross-sections aft, and Peter wasn’t going to settle for something that didn’t meet his high standards he sets for himself and his work. He built a trailer, from scratch. Late last year, three years after his diagnosis, an MRI revealed that the tumor had grown again and was inoperable. Another round of chemo and radiation was administered, but another MRI in January showed the tumor hadn’t been stopped by the treatment.

Duncan Gibbs

Duncan GibbsOn her launch day, Peter’s canoe yawl performed beautifully and looked right. The Jim was originally drawn with a leg-o’-mutton mizzen, but the lug mizzen provides a more pleasing pairing.

After such a long struggle, to get the boat so close to the finish line and fail wasn’t an option, so two old boatbuilding friends, Nick White from Conrad Blocks and Keith Davis from Pelican Slipway, came down from Brisbane to Northern New South Wales and readied Jim for a preemptive launch. There were some cleats that had yet to be installed and the deck was ’glassed but not painted, otherwise Peter’s Jim was ready to sail. On February 13, a group of his friends gathered to rig, launch, and take Peter, now very weak, for the maiden voyage of JIM. Peter said, “The process of building was really enjoyable!” In spite of his condition he was clearly enjoying the sailing too. He had an enormous grin when he was grasping the tiller and commanding his little ship.

Duncan Gibbs

Duncan GibbsPeter Sibley, craftsman

In a recent post to the forum, Peter wrote: “I suppose it’s to be expected…. The end story after a life of reasonably high energy and the ability to do most of what I wanted to achieve. The medicos have made it plain there is no way back from a glioblastoma, they don’t go away. I’m disappointed that the game is up, but I’m 69 so can’t really complain. Here was NEXT BOAT, someone should build her!”![]()

With gratitude for the example Peter set by his devotion to boatbuilding and to family.

Thanks to Peter’s friend, Duncan Gibbs, for his help with this story.

Editor’s note, May 28, 2019: We received word that Peter passed away on this day.

Peter’s Shops

Peter Sibley

Peter SibleyThe foundry has its own building, set apart from the wood-filled main shop.

Peter Sibley

Peter SibleyThe foundry’s furnace sits on a mobile frame that has a swing arm for the lid and a device to lift the furnace’s top half for easier loading.

Peter Sibley

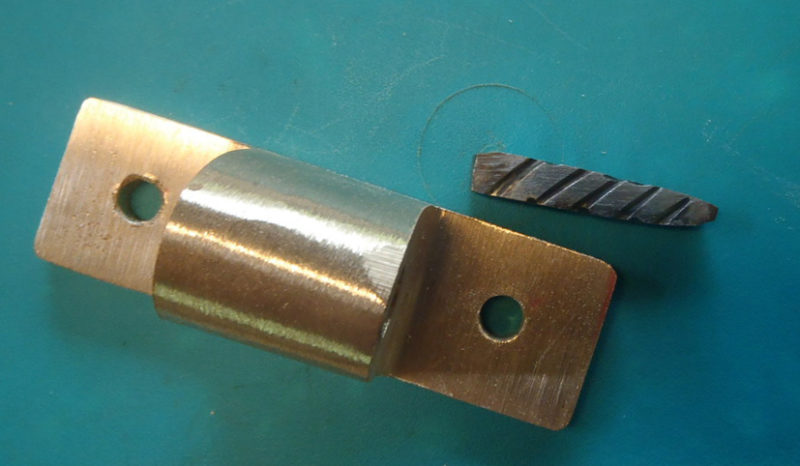

Peter SibleyThe hardware for the boat started as wooden patterns to be molded in sand and cast in bronze.

Peter Sibley

Peter SibleyThe rough castings were ready for smoothing, drilling, and polishing.

Peter Sibley

Peter SibleyFor smoothing bronze castings, Peter uses a linisher/belt grinder that he built with plywood wheels.

Peter Sibley

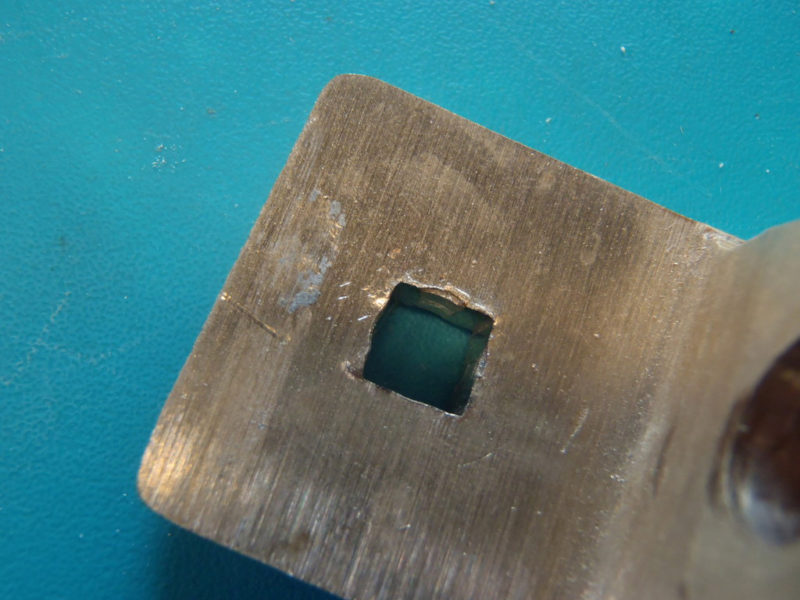

Peter SibleyAfter smoothing this gudgeon on his linisher, Peter drilled holes for the bolts. The next step was to push this shop-made broach, as it’s called, through the holes to make them square and hold the heads of carriage bolts.

Peter Sibley

Peter SibleyAfter the broach has done its job, the hole is ready for carriage bolts.

Peter Sibley

Peter SibleyThe finished fitting for the bow painter is a strong and elegant piece of hardware.

Peter Sibley

Peter SibleyThe boatbuilding shed is filled with lumber Peter milled with his horizontal bandsaw.

Peter Sibley

Peter SibleyWhen he was running a sawmill business, Peter made this gantry crane to pull logs up on his flatbed truck.

Peter Sibley

Peter SibleyThe bandsaw mill Peter built has hydraulic controls for easy operation.

Peter Sibley

Peter SibleyThe Jim nears completion. The table saw on the boat’s starboard side was mobile to make it easy to orient it for crosscutting or ripping.

Peter Sibley

Peter SibleyThe table saw is supported by four ball bearings that ride in slots on top of a wooden frame fitted with casters. A threaded rod, spun by a drill as needed, pulls the machine, and the bearings ride up the slopes cut in the slots, lifting the table saw from the floor.

Peter Sibley

Peter SibleyPeter’s homemade planking clamps are tightened with wing nuts on bolts. To spin and tighten the wing nuts quickly, he put a slot in a piece of steel tube to straddle the wings and put a rod in the tube’s other end to fit a cordless drill.

Peter Sibley

Peter SibleyThe cleats for the canoe yawl were beautifully sculpted.

Carole Sibley

Carole SibleyPeter’s friends are bonded together by something stronger than epoxy. From left to right: Gary Pick, Bruce Moffatt, Duncan Gibbs, Peter, and Tom Weiss

The sign is awesome. Quite a lot to learn in this story about boatbuilding, friends, and life from the Sibleys.

Fair winds,

Kent and Audrey

Much admiration and the very best to Mr. Sibley, whose quiet determination and courage speaks volumes.

Fair winds indeed,

Doug Lee

A very fine article about a very fine man.

I’m really glad to see this story in Small Boats Monthly. Peter has been an inspiration to many of us on the WoodenBoat Forum.

Beautiful story. May we all achieve our dreams with such grace in the time allotted to us.

A remarkable man, an inspirational story, and a beautiful boat.

Peter,

Wonderful job! Glad to see you’ve gotten to sail on your Jim.

I want to thank you for your inspiration in developing the Kathleen Gee!

Good to see you in your natural surroundings!

You keep surprising everyone. No reason to stop now!

Yours,

Tony

Peter is always inspirational and his knowledge knows no bounds, which he always finds time to share for those of us that are not gifted.

Quite a story. I’d be very interested to see the French pilot cutter he drew with Ed Burnett.

I thought that this was a wonderful article and showed a nice slice of all the talent, ingenuity, and determination that makes Peter who he is. He’s also a kind and generous man who shares what he knows and what he learns. While you may not know this about Peter, he also grows seedling trees to re-plant forest, probably something he got into when in the lumber business.

Peter inspired me with his energy he captivated me when he talked; I will remember him as a man who had a great energy and passion for life.