Christopher Cunningham

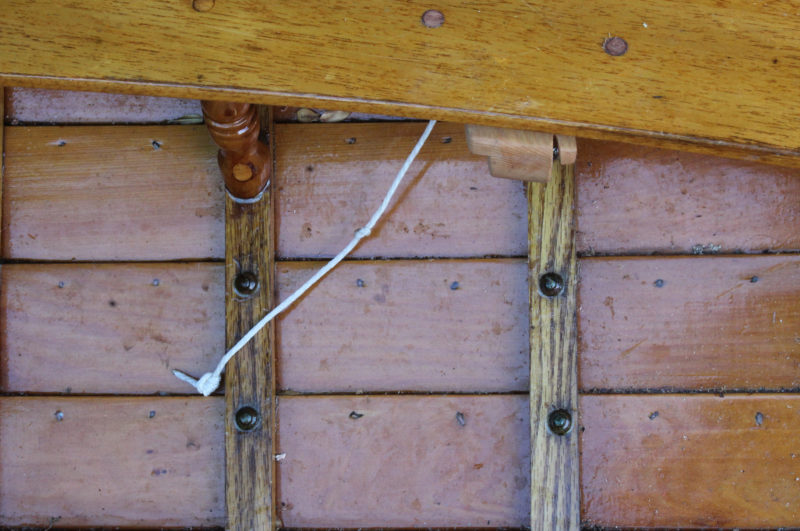

Christopher CunninghamA push-pull tiller requires a different kind of keeper than one for a conventional tiller.

Solo sailors of small open boats have a problem: While we’re sailing we’re stuck minding the helm. Occasionally there’s a need to go forward to adjust the downhaul or centerboard, use both hands to steady the binoculars, change a setting on the GPS, or eat lunch. Some boats can hold a course on their own, with the sails set to provide a neutral helm, but not always, and not on every point of sail. Some boats, like mine, have weather helm when beating and will round up if you let go of the tiller. Heaving-to takes time and brings progress to a halt.

A tiller keeper is a device to hold the tiller and maintain a course while we tend to those other chores. There are many meant for conventional tillers, available both commercially available and as do-it-yourself projects, but there are not so many for the Norwegian-style, push-pull tillers. The best I have seen was the ingenious and elegant design that Eric Hvalsoe had developed for his BANDWAGON, which Tim Yeadon also implemented on his Hvalsoe-designed HAVERCHUCK. Like their boats, my FIRE-DRAKE has a Norwegian tiller to work around a mizzenmast, so I was eager to make a tiller keeper.

Alex zimmerman

Alex zimmermanThe author’s tiller keeper is mounted on a bulkhead and has an elastic band to keep the tiller held tightly against the pin in the block shown here.

Alex Zimmerman

Alex ZimmermanThe weight of the tiller is enough to keep it in place in mild conditions; the bungee adds security when the going gets bouncy.

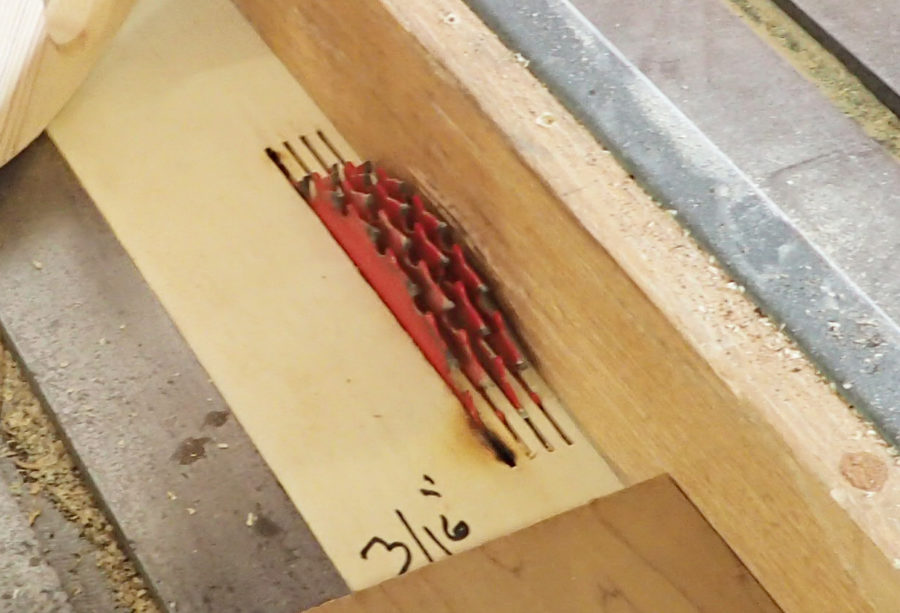

The keeper is a block of hardwood with a recess to hold the tiller from moving laterally. The wooden block I made is about 3-1/2″ wide by 3″ tall by 7/8″ thick, which nicely accommodates my 1″-square tiller arm. In the center of the saddle is a vertical stainless-steel pin. An aluminum strip, screwed and epoxied flush into the underside of the arm, has a number of holes drilled fore and aft of the rudder’s neutral position to allow for a number of positions for the tiller so I can dial in how much rudder angle I need. The pin is a 10-24 stainless-steel machine screw with the head filed to the same diameter as the shaft—just a touch larger than 3/16″—and rounded, set in epoxy about ¼” proud of the surface it sits in. The holes in the tiller’s aluminum strip are 13/64″, to make it easy to drop the tiller arm in place with the pin easily slipping into one of the holes, but not so loose as to be sloppy. The 19 holes are spaced 5/16″ on centers.

Christopher Cuningham

Christopher CuninghamThe editor’s system has the same kind of fitting set into the underside of the tiller as the author’s rig, but the block with the pin had to be mounted under the stern sheets.

Christopher Cunningham

Christopher CunninghamA light cord snugged into a V-shaped notch serves the same function as the author’s bungee.

Christopher Cunningham

Christopher CunninghamWhen not in use, the block, which has a T-shaped cross section, slides out of the way under the stern sheets, supported by a pair of notched supports.

Different tillers would have block, pin, and strip dimensions suited for their size. The pin and strip could be made of bronze or brass. There is a vertical groove at the back of the wooden block for a piece of shock cord that goes over the top of the tiller arm to a jam cleat on the other side. I have mounted the block on the forward side of the aft watertight compartment bulkhead, but it could also be mounted on a suitable thwart.

Most of the time I just drop the tiller onto the appropriate pin and let gravity hold it there. For extra security in a bit of a chop, I pull the shock cord across and cleat it. This tiller keeper is easy to make, easy to install, and it has allowed me to tend to all of those little chores underway. Now that I don’t need to mind the tiller every moment, I am not as tired at the end of a long day of sailing.![]()

Alex Zimmerman is a semi-retired mechanical technologist and former executive. His first boat was an abandoned Chestnut canoe that he fixed up as a teenager and paddled on the waterways of eastern Manitoba and northwestern Ontario. He started his professional career as a maritime engineer in the Canadian Navy, and that triggered his interest in sailing. He didn’t get back into boatbuilding until he moved back to Vancouver Island in the ’90s, where he built a number of sea kayaks that he used to explore the coast. In the early 2000s, he built his first sail-and-oar boat and he completed his latest in June of this year. He says he can stop building boats any time.

You can share your tricks of the trade with other Small Boats Monthly readers by sending us an email.

This is pretty neat. I may well add it to one of my push pull tillers. One thing they all get is a lanyard of just the right length so I can steer, but it keeps me from dropping the tiller over board. It never can get more than a few inches from the hull. The Norwegians didn’t need this; I certainly do.

This article is a great help to me. I’ve read about this style of keeper, but I just couldn’t visualize it. Thanks very much. Now I’ll have no trouble adapting it to my own Norwegian tiller.

I’m grateful to you for showing us the way, Eric. I hadn’t had time between completing the boat and setting out on last summer’s trip to make one of these, so I had to improvise with a very short sticky rubber bungee wrapped around the tiller and a longer fabric-covered bungee from the lifting padeye to hold it in place. It was both awkward and inadequate, as you say. It needed constant adjustment because of the slipping. This is so much better.

Thank you for the acknowledgment Alex.

The trick and the mental journey was to apply the idea of a tiller comb to a push-pull stick. I was aware of no previous solution. Tension from only a lashing or shock cord is inadequate and/or clumsy, in my experience. BANDWAGON’s tender is mounted on the main thwart knee which affords a less extreme angle for the pushstick across the saddle of the device. In BANDWAGON’s case, mid-boom sheeting allows me quite a long stick. Chris’s adaption makes a lot of sense as well. It is important that the device be unobtrusive. I can hardly imagine sailing without it. My pin and index plate are brass and copper.

Nice idea, a bit simpler than the “jaws” I made, attached to my outrigger canoe aft cross beam and squeezed together with a bungee to “bite” the pole. But I have generally had to just heave-to under the mizzen for the most reliable method to adjust something since my boat does not track well after I shift my weight more than a couple of feet.

Just a thought. What if instead of the pin and plate with holes, industrial Velcro was used which would give total variability. It could be glued with construction adhesive and reinforced with small brass screws.

It’s worth a try. The hook side of some types of Velcro can snag some clothing and loosely woven fabrics, so consider unwelcome attachments.

Velcro is an interesting idea. Experiment away. On the other hand the hard pin is both completely secure yet the stick lifts with a fingertip at least in light conditions. When first noodling through this idea I was also concerned about infinite adjustability. It does not now seem a problem to me with stops as close as 1/4 or 5/16″. Helm pressure and trim can, of course, be influenced by several other factors in our little boats. There is a little bit of slop built into BANDWAGON’s entire system at every part – indexing, push-stick/cross-arm lashing,

cross-arm mount to rudder, maybe even gudgeons and pintles. The rudder is free to wiggle a wee bit.

Thanks for an excellent idea. I am putting the finishing touches on SMAUG, my 15′ Viking Dragon Ship and I will definitely include the tiller keeper.